High magnetic rotational flow self power generation vacuum superconductivity quadruple effect paraffin control and viscosity reduction device

A self-generating, strong magnetic technology, applied in vibration generating devices, isolation devices, cleaning appliances, etc., can solve problems such as uneconomical and difficult, and achieve the effects of simple and convenient construction, long time period, and low investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

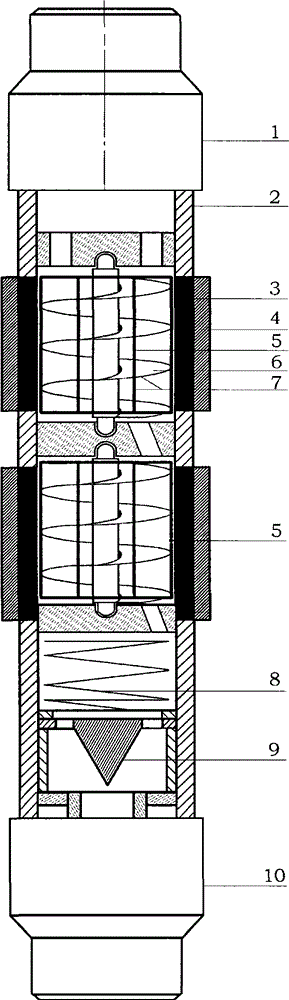

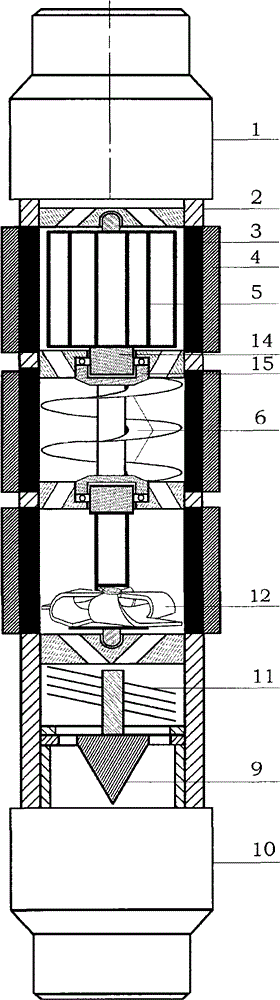

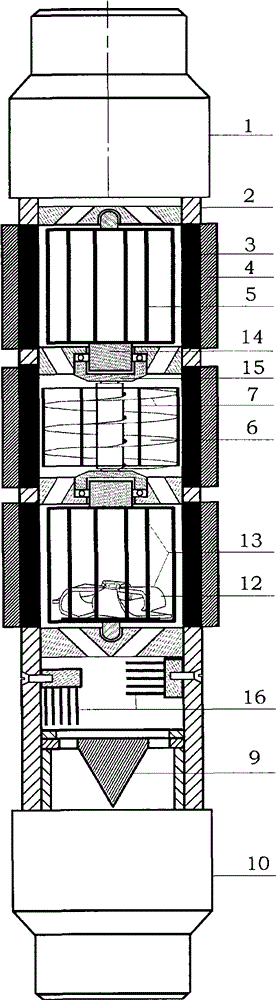

[0043] Such as figure 1 As shown: the strong magnetic swirl self-generating vacuum superconducting four-effect anti-wax viscosity-reducing device of the present invention includes single-stage or multi-stage high-frequency pulse hydraulic oscillation anti-wax viscosity-reducing devices connected in series from bottom to top with threaded fasteners, strong The magnetic swirl flow self-generating device and the upper variable button joint (1) connecting the upper part of the device to the oil well pump and the lower variable button connector (10) connecting the lower part of the device to the tailpipe, the connection positions of the above devices can be randomly combined and interchanged, and the assembled The number of stages can be adjusted according to the heating requirements, and oblique jet holes which are conducive to the formation of spiral swirl flow are arranged between the stages to communicate with each other.

[0044] The high-frequency pulse hydraulic oscillation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com