Ground gas turbine using pulse knocking combustion

A pulse detonation, gas turbine technology, applied in gas turbine devices, deflagration combustion chambers, combustion chambers, etc., can solve the problems of complex combustion chamber structure, narrow combustion stability area, small air ratio, etc., and achieves low requirements for materials and cooling technology , The effect of short residence time and fast burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

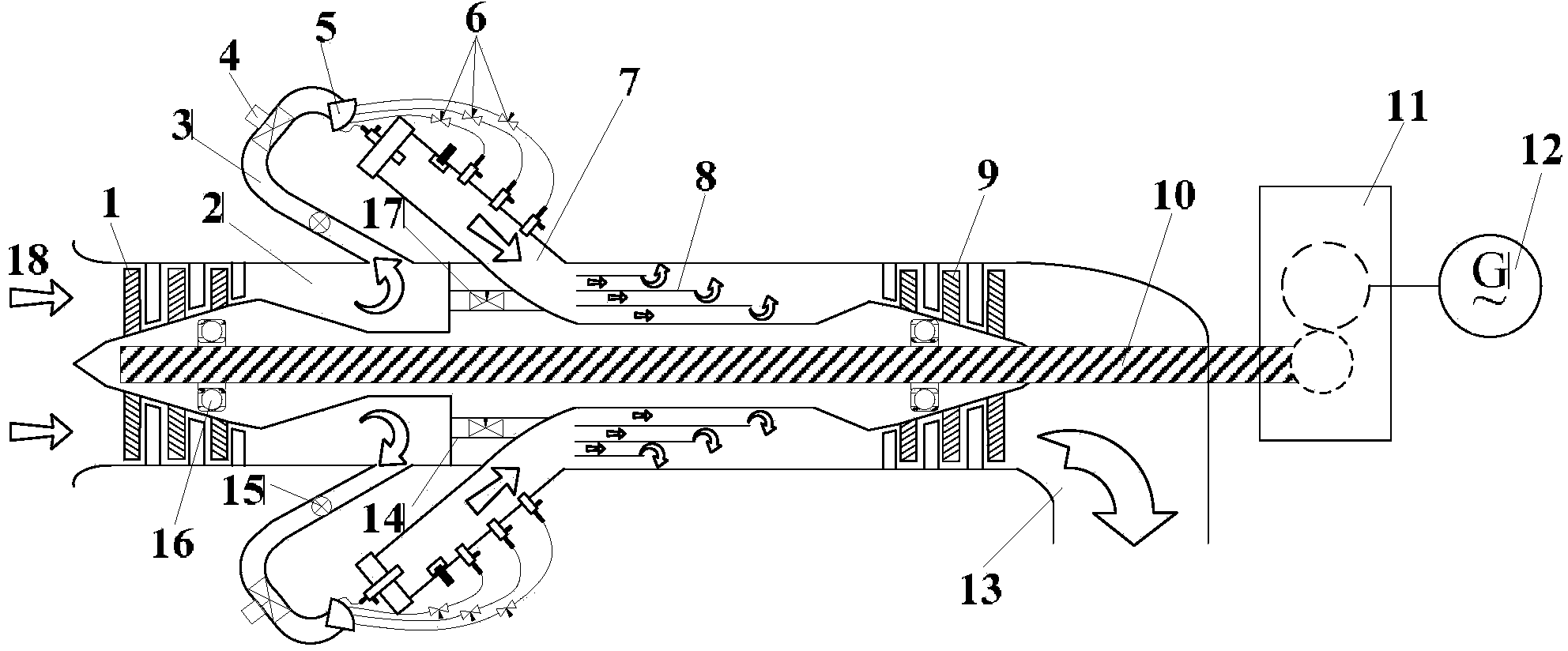

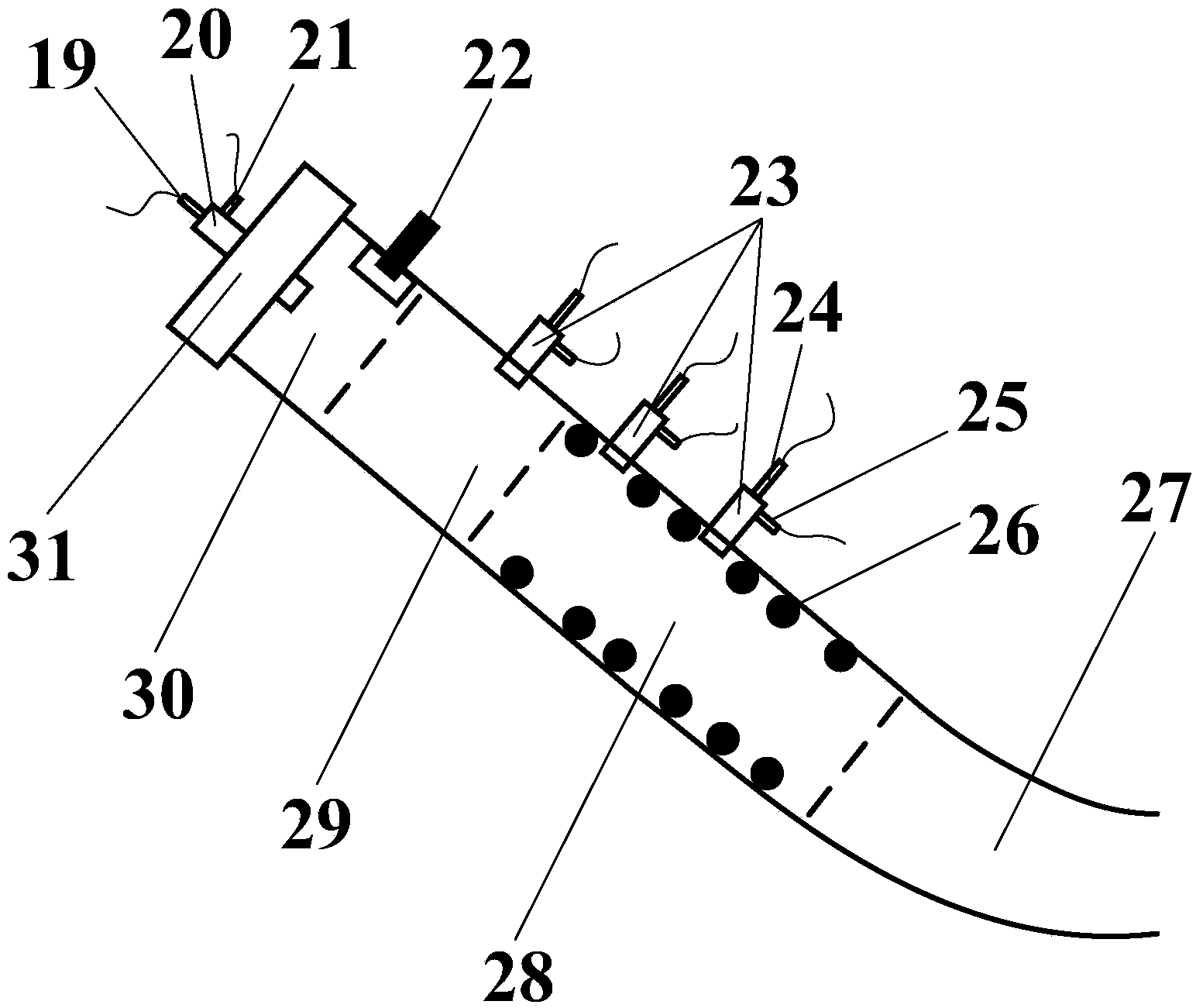

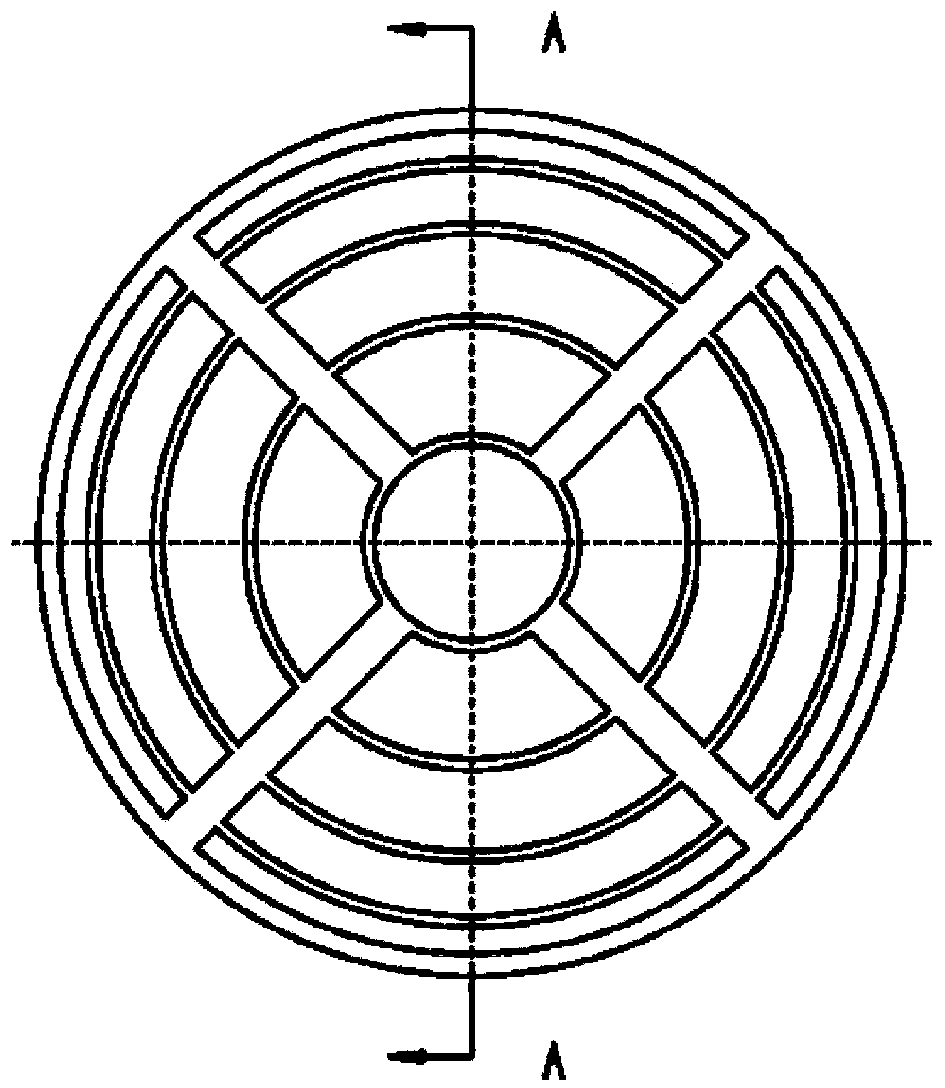

[0029] see figure 1 , a ground gas turbine using pulse detonation combustion in the present invention, comprising a compressor 1, a gas storage chamber 2, a plurality of gas supply pipelines 3, a plurality of pulse detonation combustion chambers 7, a pressure shaping chamber 8, a turbine 9, and a rotor 10 and tailpipe 13, and formed as figure 1 The flow path of the combustion gas passing through them indicated by the middle arrow, that is, the combustion gas flow path 18 .

[0030] Among them, the compressor 1 is arranged at the front end of the ground gas turbine, the gas outlet of the compressor 1 is connected with the gas storage chamber 2, the pressure shaping chamber 8, the turbine 9 and the tail nozzle 13 in sequence, and the rotor 10 is arranged between the compressor 1 and The center of the turbine 9 is connected to the compressor 1 and the turbine 9 respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com