Positive infrared sensitive composition and imaging element thereof

A composition and infrared technology, which is applied in the field of imageable components for positive plate making and positive infrared sensitive composition, can solve problems such as erosion and unfavorable lithography, and achieve the effect of prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The positive infrared sensitive composition described in the present embodiment comprises:

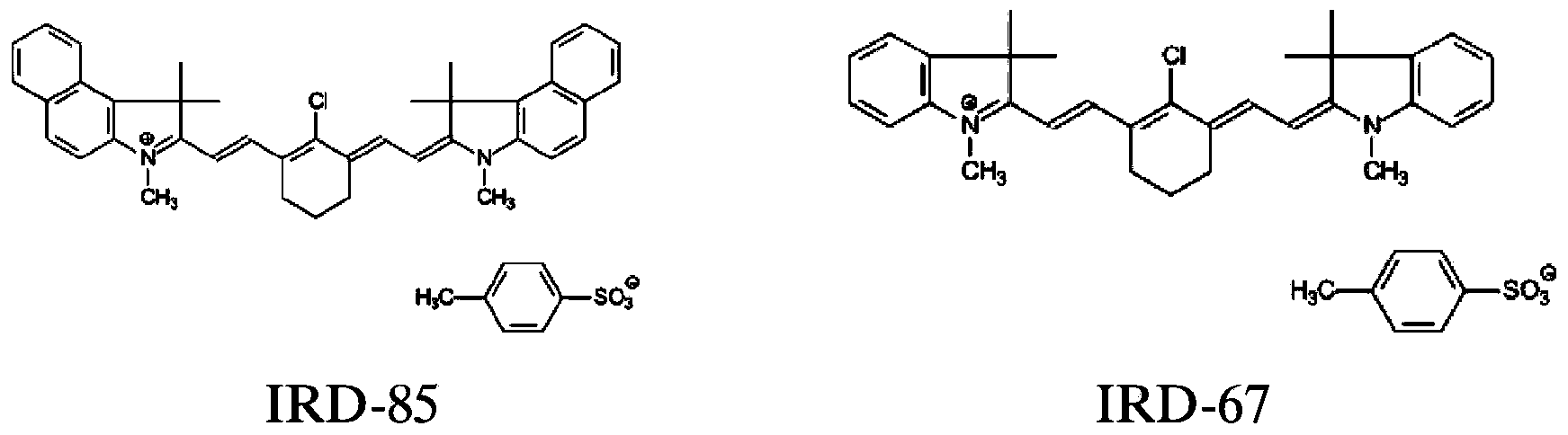

[0041] Cyanine dye IRD-85, 0.2 parts by weight, purchased from DKSH Holding Ltd.;

[0042] Methyl violet, 0.14 parts by weight;

[0043] Diphenyliodonium hexafluorophosphate, 0.20 parts by weight;

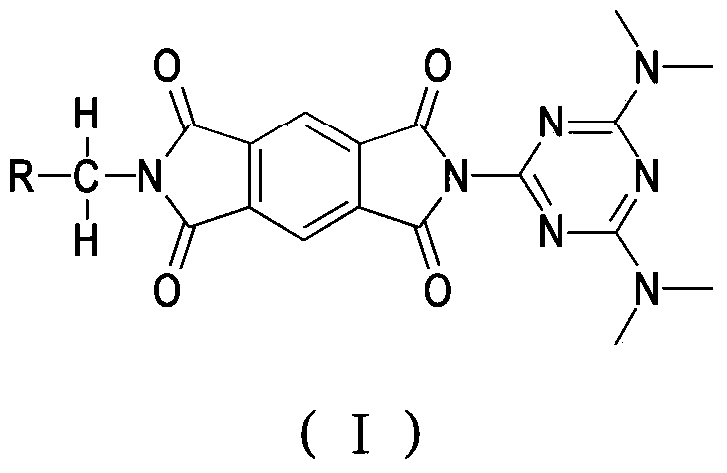

[0044] Polymer, 6.16 parts by weight; The polymer includes a main chain LB6564 resin with a phenolic repeating unit and a substituting group covalently connected with the main chain LB6564 resin, and the structure of the polymer is as shown in formula (I) Show:

[0045]

[0046] Wherein, R represents the main chain of the LB6564 resin.

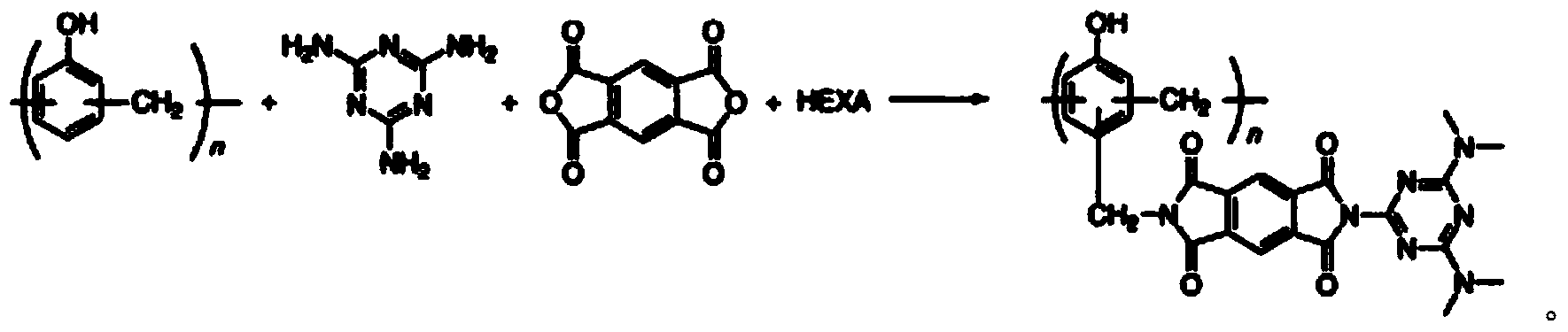

[0047] The preparation method of described polymer is as follows:

[0048] In a closed fume hood, add 5 parts by weight of dry LB6564 resin (purchased from German Bakerite Company) and 40.8 parts by weight of DMF to a four-necked round bottom flask equipped with mechanical stirring, thermometer, reflux condenser and constant pressure funnel. ...

Embodiment 2

[0052] The positive infrared sensitive composition described in the present embodiment comprises:

[0053] Cyanine dye IRD-67, 0.2 parts by weight, purchased from DKSH Holding Ltd.;

[0054] Methyl violet, 0.14 parts by weight;

[0055] Diphenyliodonium hexafluorophosphate, 0.20 parts by weight;

[0056] Polymer, 6.16 parts by weight; The polymer includes a main chain BX-10 resin with phenolic repeating units and a substituting group covalently connected with the main chain BX-10 resin, and the structure of the polymer is as follows: (I) as shown:

[0057]

[0058] Wherein R represents the main chain of the BX-10 resin.

[0059] The preparation method of described polymer is as follows:

[0060] In a closed fume hood, add 5 parts by weight of dry BX-10 resin (purchased from Ruishida Chemical Co., Ltd. company) and 40.8 parts by weight of DMF, stirred until the BX-10 resin was completely dissolved. After the DMF solution of the BX-10 resin is clarified, add 0.5 parts b...

Embodiment 3

[0063] The positive infrared sensitive composition described in the present embodiment comprises:

[0064] Cyanine dye IRD-85, 0.2 parts by weight;

[0065] Methyl violet, 0.14 parts by weight;

[0066] Triphenylsulfonium hexafluorophosphate, 0.20 parts by weight;

[0067] Polymer, 6.16 parts by weight; The polymer includes a main chain BTB-225 resin with phenolic repeating units and a substituting group covalently connected with the main chain BTB-225 resin, and the structure of the polymer is as follows: (I) as shown:

[0068]

[0069] Wherein R represents the main chain of the BTB-225 resin.

[0070] The preparation method of described polymer is as follows:

[0071] In a closed fume hood, add 5 parts by weight of dry BTB-225 resin (purchased from Tiancheng Chemical Industry Co., Ltd. Co., Ltd.) and 40.8 parts by weight of DMF, stirred until the BTB-225 resin was completely dissolved. After the DMF solution of the BTB-225 resin is clarified, add 0.5 parts by weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com