Electrolyte capacitor, and method for producing same

一种电解电容器、制造方法的技术,应用在电解电容器制造、电解电容器、电容器等方向,能够解决未能获得电解电容器等问题,达到可靠性高、耐热性优良、等效串联电阻低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

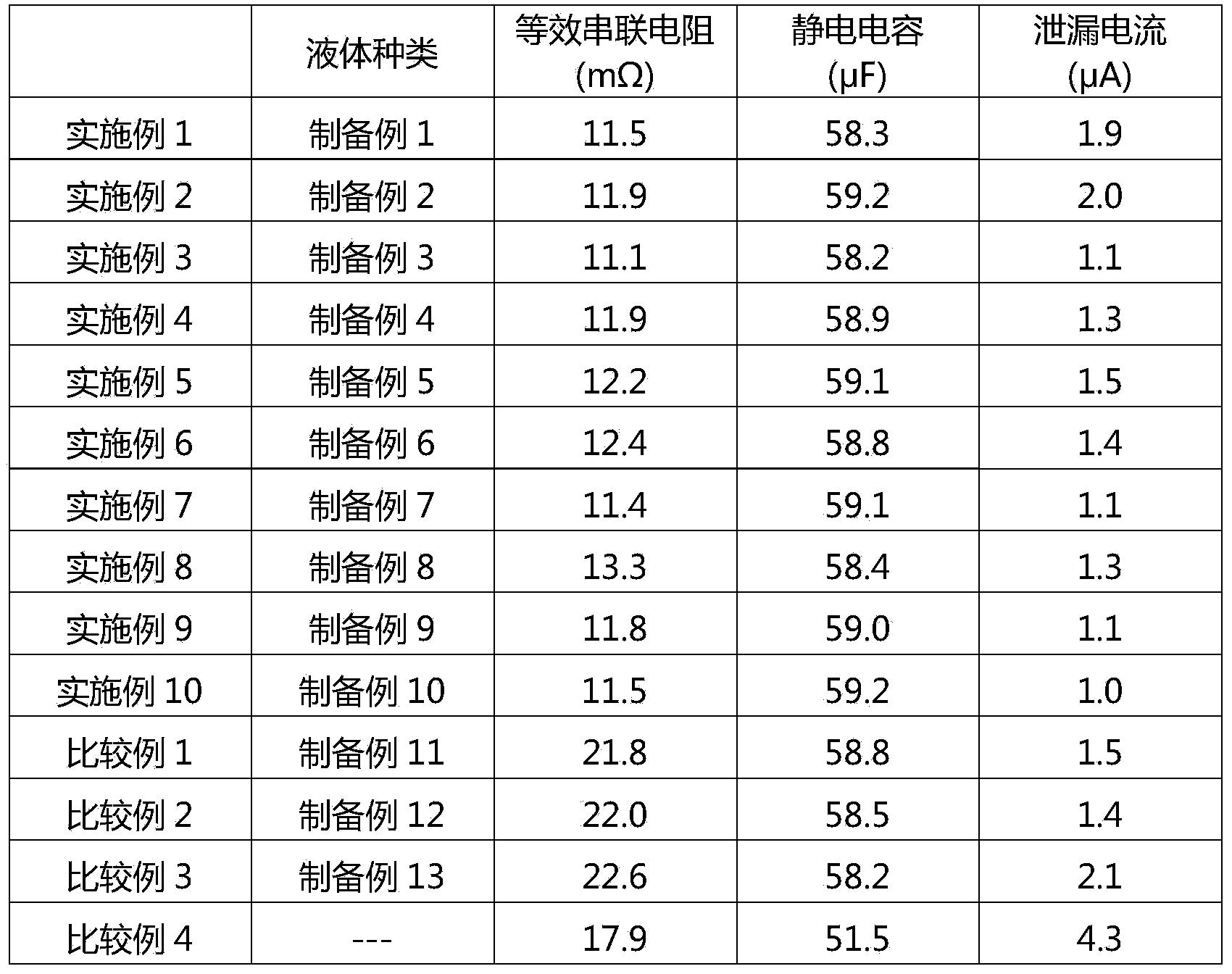

[0109] The following examples are given to describe the present invention more specifically, but the present invention is not limited to the contents illustrated in these examples. In addition, in the following examples etc., % when showing a concentration or usage-amount is a % based on a mass basis, unless the reference|standard is especially noted.

preparation example 1

[0112] Put 500 g of γ-butyrolactone into a 1 L beaker with a stirring device, add 50 g of hydroxybenzoic acid, 5 g of nitrophenol, and 1 g of 3-glycidoxypropyltrimethoxysilane, and stir 24 hours to prepare conductivity auxiliary solution.

[0113] The conductivity of the conductivity-assisting liquid was measured at 25° C. with a conductivity measuring device (F-55) manufactured by Horiba, Ltd., and the conductivity of the conductivity-assisting liquid was 16 μS / cm.

[0114] The above gamma-butyrolactone has a boiling point of 203°C, which is equivalent to a high-boiling organic solvent with a boiling point above 150°C. Hydroxybenzoic acid and nitrophenol are equivalent to aromatic compounds with at least one hydroxyl group. The concentration of aromatic compounds in the conductivity auxiliary liquid is about 9.9%, and the ratio of hydroxybenzoic acid to nitrophenol is 10:1 in terms of mass ratio. Moreover, 3-glycidoxypropyltrimethoxysilane is equivalent to the binder, and th...

preparation example 2

[0116] Put 500 g of γ-butyrolactone into a 1 L beaker with a stirring device, add 50 g of hydroxybenzoic acid, 10 g of nitrophenol, and 5 g of 3-glycidoxypropyltrimethoxysilane, and stir 24 hours to prepare a conductivity assisting liquid.

[0117] The conductivity of the conductivity-assisting liquid was measured at 25° C. with a conductivity measuring device (F-55) manufactured by Horiba, Ltd., and the conductivity of the conductivity-assisting liquid was 16 μS / cm.

[0118] The above gamma-butyrolactone has a boiling point of 203°C, which is equivalent to a high-boiling organic solvent with a boiling point above 150°C. Hydroxybenzoic acid and nitrophenol are equivalent to aromatic compounds with at least one hydroxyl group. The concentration of aromatic compounds in the conductivity auxiliary liquid is about 10.6%, and the ratio of hydroxybenzoic acid to nitrophenol is 5:1 in terms of mass ratio. And 3-glycidoxypropyltrimethoxysilane is equivalent to the binder, and the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com