Preparation method for puffed food named as Xianbei

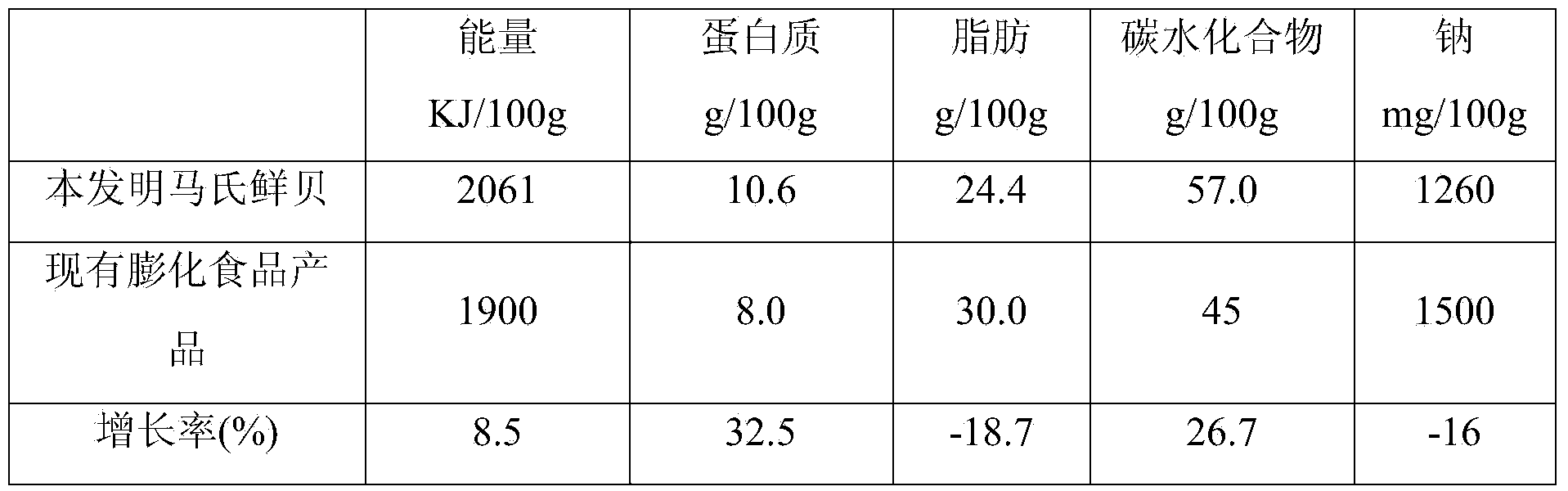

A fresh scallop and mixing technology, which is applied in the food field, can solve the problems of incomplete nutrients, high unit cost, and difficult quality assurance, and achieve the effects of rich nutrition, good quality and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The preparation method of fresh shellfish comprises the following steps:

[0027] 1. Preparation of primary mix:

[0028] 1.1 Do a good job of preparation before ingredients, clean equipment, containers and utensils, and do a good job of disinfection;

[0029] 1.2 Weigh the raw materials correctly according to the recipe requirements; the parts by weight of the raw materials for the primary mix are: 61.5 parts of rice flour, 33 parts of corn flour, 1.2 parts of calcium carbonate, 4 parts of water, 4 parts of chicken paste, and 0.3 parts of salt.

[0030] 1.3 Put rice flour, corn flour and calcium carbonate into the mixing tank, stir for 5.5 minutes,

[0031] 1.4 Put water, chicken paste and salt into the mixing tank after mixing, and continue stirring for 18 minutes to obtain the primary mixture;

[0032] 2. Expansion molding

[0033] 2.1 Turn on the main power switch of the extruder, set the temperature of each zone of the extruder, 60°C for zone I, 120°C for zone I...

Embodiment 2

[0047] The preparation method of fresh shellfish comprises the following steps:

[0048] 1. Preparation of primary mix:

[0049] 1.1 Do a good job of preparation before ingredients, clean equipment, containers and utensils, and do a good job of disinfection;

[0050] 1.2 Correctly weigh the raw materials according to the formula requirements; the weight parts of the raw materials for the primary mix are: 62 parts of rice flour, 34 parts of corn flour, 1.5 parts of calcium carbonate, 3 parts of water, 3 parts of chicken paste, and 0.2 parts of salt

[0051] 1.3 Put rice flour, corn flour and calcium carbonate into the mixing tank, stir for 5 minutes,

[0052] 1.4 Put water, chicken paste and salt into the mixing tank after mixing, and continue stirring for 20 minutes to obtain the primary mixture;

[0053] 2. Expansion molding

[0054] 2.1 Turn on the main power switch of the extruder, set the temperature of each area of the extruder, the I area is 55°C, the II area is 130...

Embodiment 3

[0068] The preparation method of fresh shellfish comprises the following steps:

[0069] 1. Preparation of primary mix:

[0070] 1.1 Do a good job of preparation before ingredients, clean equipment, containers and utensils, and do a good job of disinfection;

[0071] 1.2 Correctly weigh the raw materials according to the formula requirements; the weight parts of the raw materials for the primary mix are: 61 parts of rice flour, 32 parts of corn flour, 1.0 parts of calcium carbonate, 5 parts of water, 5 parts of chicken paste, and 0.4 parts of salt

[0072] 1.3 Put rice flour, corn flour and calcium carbonate into the mixing tank, stir for 6 minutes,

[0073] 1.4 Put water, chicken paste and salt into the mixing tank after mixing, and continue stirring for 15 minutes to obtain the primary mixture;

[0074] 2. Expansion molding

[0075] 2.1 Turn on the main power switch of the extruder, set the temperature of each zone of the extruder, 65°C for zone I, 110°C for zone II, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com