Surface pit texture subjected to edge profile modification and processing method thereof

A processing method and surface texture technology, which are applied to the surface pit texture and its processing field, can solve the problems of instability, enhanced abrasive wear, increased dual wear, etc. The effect of edge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for processing a surface pit texture through edge modification, comprising the following steps:

[0023] a. Select a piece of 4Cr13 steel (diameter 40mm, thickness 10mm) for surface polishing, and its roughness is Ra0.02~0.025μm.

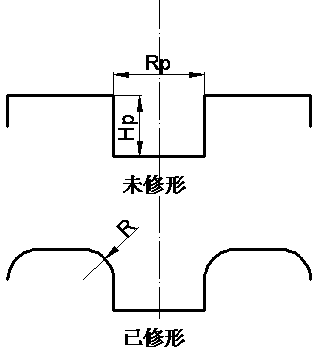

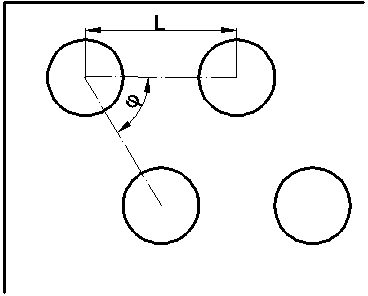

[0024] b. Use a laser to evenly punch circular pits with a diameter of Rp=50μm, a depth of Hp=20μm, a distance between centers of L=100μm and an inclination angle of φ=60° on the polished surface.

[0025] c. Use sandpaper to polish off the burrs produced by laser processing, then use a rotary grinding and polishing machine, place a rubber pad under the polishing pad, apply oily diamond polishing paste on the polishing pad, and polish the pitted stainless steel surface. In the secondary direction, the right-angled edge of the pit will be ground first after polishing, and the edge will be rounded.

[0026] d. After polishing, perform ultrasonic cleaning in n-hexane and absolute ethanol for 10 minutes, and dry naturally.

Embodiment 2

[0028] A method for processing a surface pit texture through edge modification, comprising the following steps:

[0029] a. Select a piece of 4Cr13 steel (diameter 40mm, thickness 10mm) for surface polishing, and its roughness is controlled at Ra0.02~0.025μm.

[0030] b. Use a laser to evenly punch circular pits with a diameter of Rp=100μm, a depth of Hp=20μm, a distance between centers of circles of L=200μm, and an inclination angle of φ=90°.

[0031] c. Use sandpaper to polish off the burrs produced by laser processing, and then electropolish the processed surface. After electropolishing, the right-angled edge of the pit will be dissolved first, and the edge will collapse into a circular arc.

[0032] d. After polishing, perform ultrasonic cleaning in n-hexane and absolute ethanol for 10 minutes, and dry naturally.

Embodiment 3

[0034] A method for processing a surface pit texture through edge modification, comprising the following steps:

[0035] a. Select a piece of polystyrene (diameter 40mm, thickness 10mm) and polish the surface with a roughness of Ra1μm.

[0036] b. Use a laser to evenly punch circular pits with a diameter of Rp=100μm, a depth of Hp=20μm, a distance between centers of circles of L=200μm, and an inclination angle of φ=90°.

[0037] c. Use sandpaper to polish off the burrs produced by laser processing, and then use a rotary grinding and polishing machine, place a rubber pad under the polishing pad, apply oily diamond polishing paste on the polishing pad, and polish the polystyrene surface with pits. After changing the direction several times, the right-angled edge of the pit will be ground first after polishing, and the edge will be rounded.

[0038] d. After polishing, perform ultrasonic cleaning in n-hexane and absolute ethanol for 10 minutes, and dry naturally.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com