Treatment and Reuse Method of Sewage from Oil Refining-Ethylene Combined Unit

A technology of combined device and mixed sewage, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, natural water treatment, etc. Unsatisfactory, large investment in sewage reuse, etc., to achieve the effect of reducing the amount of difficult-to-treat sewage, covering a large area, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

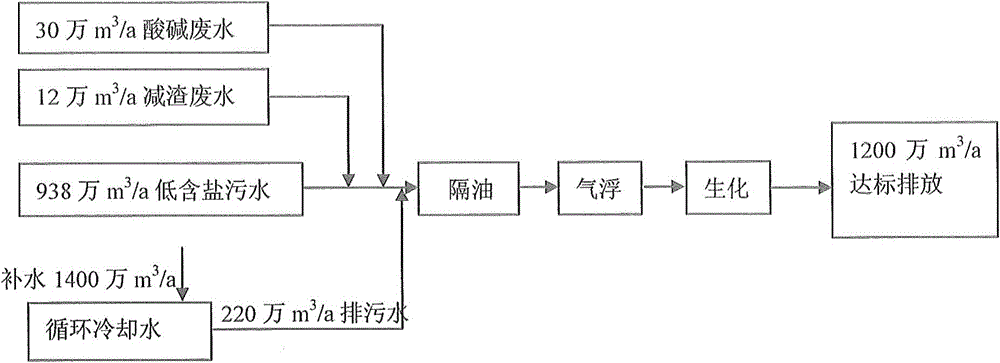

[0056] The conditions of the ethylene production unit and various sewage are the same as those of Comparative Example 1.

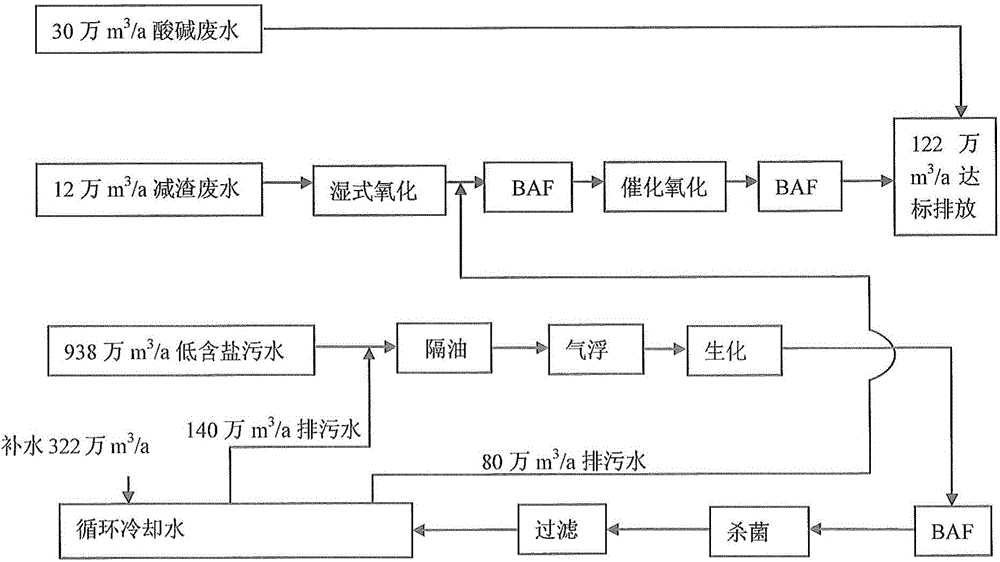

[0057] Such as figure 2 As shown, the alkali slag wastewater, acid-base wastewater and part of the circulating cooling water sewage are cut out from the wastewater treatment system; 120,000 m 3 / a of alkali slag wastewater after wet oxidation treatment, and 800,000 m 3 / a of circulating cooling water and sewage mixed, the mixed COD3 / a acid-alkali wastewater is mixed and discharged, the COD of the discharged sewage is <60mg / L, and the water quality reaches the national environmental first-level discharge standard; among them, after the first BAF treatment, the B / C of the sewage is <0.3, and the COD<200mg / L L.

[0058] 9.38 million m3 with salt content less than 500mg / L 3 / a waste water and 1.4 million m 3 / a The sewage from the circulating cooling water system is mixed. After being treated by the sewage treatment system in Comparative Example 1, the B...

Embodiment 2

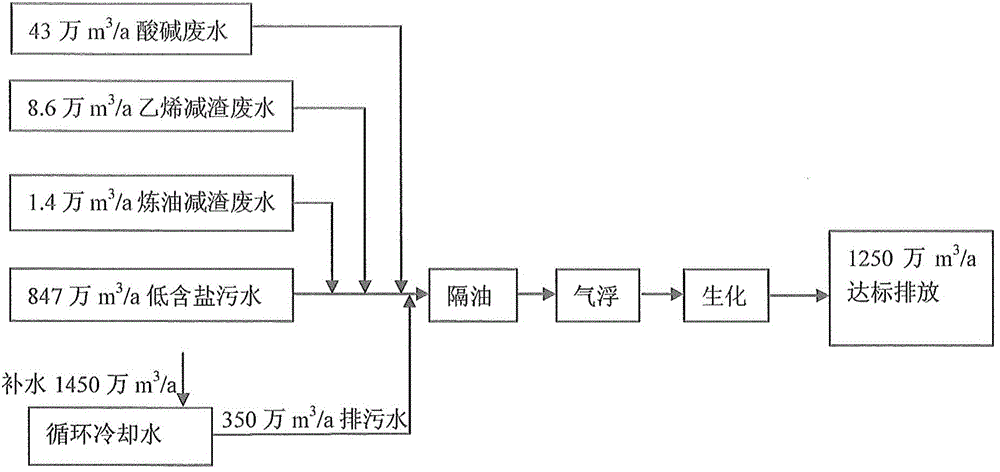

[0063] The situation of the production device and various sewage is the same as that of Comparative Example 2.

[0064] Such as Figure 4 As shown, the oil refining alkali residue wastewater, ethylene alkali residue wastewater, acid-base wastewater and part of the circulating cooling water sewage are cut out from the wastewater treatment system, and the 14,000 m3 treated by "wet oxidation + SBR" 3 / a Refinery alkali slag wastewater, 86,000 m of wet oxidation treatment 3 / a Ethylene alkali slag wastewater and 1.5 million m3 of salt containing 1800mg / L 3 / a The sewage from the circulating cooling water system is combined and treated with the "BAF + catalytic oxidation + BAF" process, and the effluent is then combined with 430,000 m 3 / a The acid-base wastewater is combined and discharged, the COD of the discharged sewage is less than 60mg / L, and the water quality reaches the national environmental first-level discharge standard; among them, after the first BAF treatment, the B...

Embodiment 3

[0070] The conditions of the ethylene production unit and various sewage are the same as those of Comparative Example 3.

[0071] Such as Figure 6 As shown, the alkali slag wastewater, acid-base wastewater and part of the circulating cooling water sewage are cut out from the wastewater treatment system; 45,000 m 3 / a Alkaline slag waste water after wet oxidation treatment, with 800,000 m 3 / a The sewage from the circulating cooling water system is mixed, and the COD after mixing is 3 / a The acid-base wastewater is mixed and discharged, the COD of the discharged sewage is less than 60mg / L, and the water quality reaches the national environmental first-level discharge standard; among them, after the first BAF treatment, the B / C of the sewage is 0.1-0.4, and the COD is less than 200mg / L.

[0072] 2.545 million m with salt content less than 500mg / L 3 / a Waste water is treated by the sewage treatment system of Comparative Example 3, and then treated with BAF process. The salt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com