A kind of graphene ceramic composite material prepared by sol-gel method and preparation method thereof

A technology of ceramic composite materials and ceramic materials, which is applied in the field of composite material preparation, can solve problems such as poor dispersion and easy agglomeration of graphene, and achieve the effects of not being easy to agglomerate, solving easy agglomeration, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

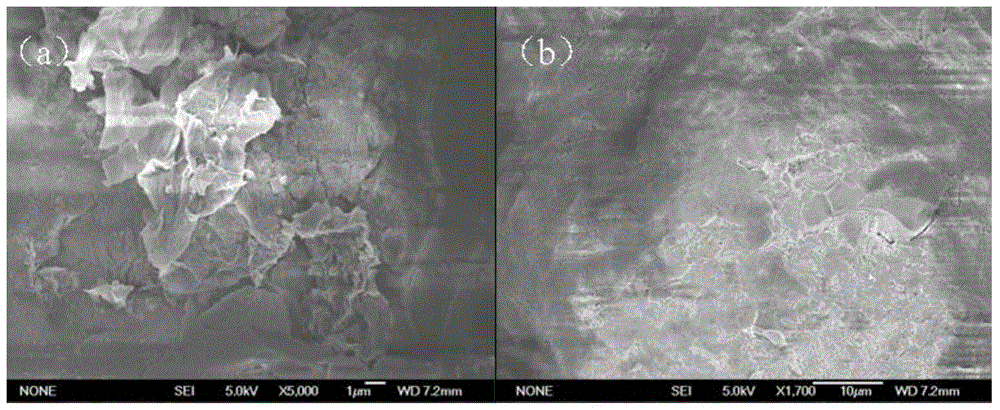

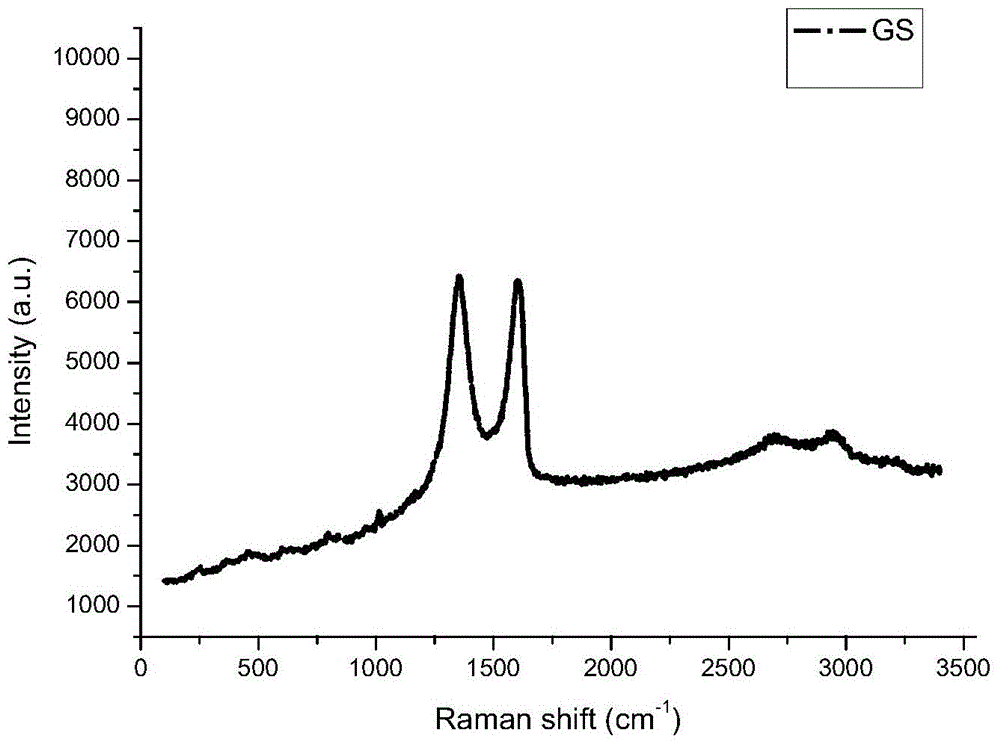

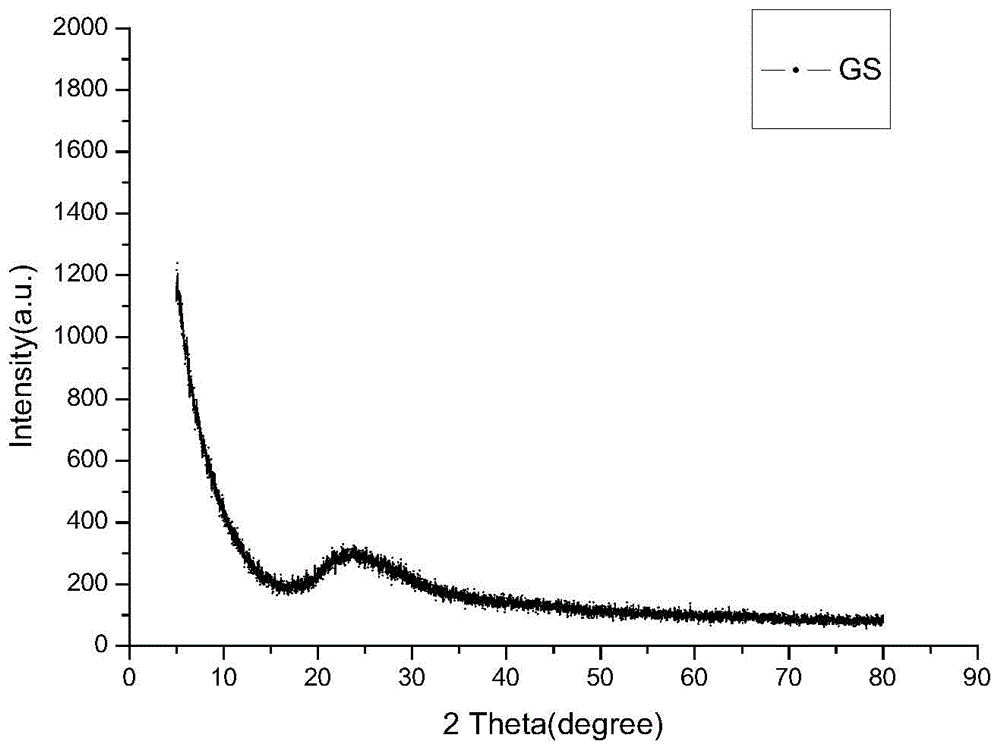

Image

Examples

Embodiment 1

[0043] In this embodiment, tetraethyl silicate is used as a ceramic precursor, and a graphene ceramic composite material is prepared according to the following steps:

[0044] a. Dissolve 0.15 g of graphene oxide in 20 mL of distilled water, and disperse ultrasonically for 2 hours to obtain a graphene oxide suspension;

[0045] b. Add 20 mL of tetraethyl silicate (TEOS) and 10 mL of absolute ethanol to the graphene oxide suspension obtained in step a, stir at room temperature for 2 h, then add 40 mL of distilled water to obtain a solution to be reacted;

[0046] c. In a cold water bath with a temperature of 10°C, add 1M HCl to the reaction solution obtained in step b while stirring until pH = 1, then continue to stir in a cold water bath for 1 hour, and finally add 30 mL of absolute ethanol Continue to stir for 10 minutes;

[0047] d. Remove the cold water bath, and then heat and stir the solution obtained in step c at 50° C. for 7 days, and the solution becomes a black jelly; ...

Embodiment 2

[0055] In this embodiment, aluminum sec-butoxide is used as a ceramic precursor, and a graphene ceramic composite material is prepared according to the following steps:

[0056] a. Dissolve 0.3g of graphene oxide in 20mL of distilled water, and ultrasonically disperse to obtain a graphene oxide suspension;

[0057] b. Add 20 mL of aluminum sec-butoxide and 10 mL of absolute ethanol to the graphene oxide suspension obtained in step a, stir at room temperature for 2 h, then add 40 mL of distilled water to obtain a solution to be reacted;

[0058] c. In a cold water bath with a temperature of 10°C, add 2M NaOH to the solution to be reacted in step b while stirring until pH = 8, then continue to stir in the cold water bath for 1 hour, and finally add 30 mL of absolute ethanol to continue stirring 10min;

[0059] d. Remove the cold water bath, and then heat and stir the solution obtained in step c at 50° C. for 3 days, and the solution becomes a black jelly;

[0060] e. Bake the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com