Method of preparing carboxymethylcellulose by use of manioc waste

A technology of carboxymethyl cellulose and cassava residues, applied in the field of preparation methods of carboxymethyl cellulose, can solve problems such as inability to handle rationally, cassava residues pollute the environment, etc. The effect of increasing income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

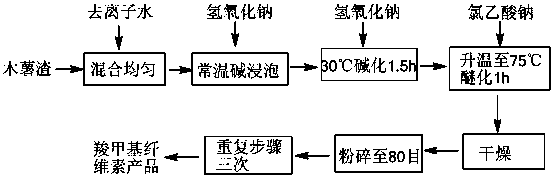

Method used

Image

Examples

Embodiment 1

[0010] Example 1: Measure 50.0 ml of deionized water and add it into a reaction vessel, weigh 10 g of cassava residue, and add the cassava residue under constant stirring. Weigh 0.823g of sodium hydroxide and dissolve it in 5ml of deionized water. After the heat release is complete and the sodium hydroxide is completely dissolved, add it to the reaction vessel and soak for 6 hours, then raise the temperature to 30°C for 1.5 hours of alkalization under constant stirring, accurately Weigh 2.40g of sodium chloroacetate and dissolve it in 10ml of deionized water, raise the temperature to 75°C, slowly add the above solution under stirring to etherify for 1h, dry and crush to 80 mesh, repeat the above steps three times to obtain carboxymethyl with a substitution degree of 0.20 Cellulose-based products;

Embodiment 2

[0011] Example 2: Measure 50.0 ml of deionized water and add it into the reaction container, weigh 10 g of cassava residue, and add the cassava residue under constant stirring. Weigh 1.00g of sodium hydroxide and dissolve it in 5ml of deionized water. After the exotherm is complete and the sodium hydroxide is completely dissolved, add it to the reaction vessel and soak for 6 hours, then raise the temperature to 30°C for 1.5 hours with constant stirring, and make it alkaline for 1.5 hours. Weigh 3.595g of sodium chloroacetate and dissolve it in 10ml of deionized water, raise the temperature to 75°C, slowly add the above solution under stirring to etherify for 1 hour, dry and crush to 80 mesh, repeat the above steps three times to obtain carboxymethyl with a substitution degree of 0.29 Cellulose-based products;

Embodiment 3

[0012] Example 3: Measure 50.0 ml of deionized water and add it into the reaction vessel, weigh 10 g of potato residues, and add the potato residues under constant stirring. Weigh 1.235g of sodium hydroxide and dissolve it in 5ml of deionized water. After the heat release is complete and the sodium hydroxide is completely dissolved, add it to the reaction vessel and soak for 6 hours, then raise the temperature to 30°C for 1.5 hours under constant stirring, and make it alkaline for 1.5 hours. Weigh 2.40g of sodium chloroacetate and dissolve it in 10ml of deionized water, raise the temperature to 75°C and slowly add the above solution under stirring to etherify for 1h, dry and crush to 80 mesh, repeat the above steps three times to obtain carboxymethyl with a substitution degree of 0.38 Cellulose-based products;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com