A Reduction Reaction Shaft Furnace Waste Heat Recovery and Recycling System

A waste heat recovery and shaft furnace technology, applied in shaft furnaces, furnaces, waste heat treatment and other directions, can solve the problems of large heat energy waste and low waste heat recovery efficiency, and achieve the effects of high waste heat recovery and utilization efficiency, reduced emissions, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

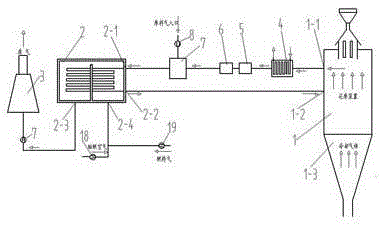

Embodiment 1

[0022] like figure 1 As shown, a reduction reaction shaft furnace waste heat recovery and recycling system includes a shaft furnace 1, a reformer 2 and a waste gas discharge device 3, and the shaft furnace 1 is provided with a first exhaust port 1-1 and a reducing gas inlet 1 -2, the reformer 2 is provided with a raw material gas inlet 2-1 and a reducing gas outlet 2-2, and a first gas is sequentially connected between the exhaust port 1-1 and the raw material gas inlet 2-1 Water heat exchanger 4, scrubber 5, carbon dioxide absorption device 6 and the first mixing chamber 7, the first pressurizer 8 is arranged between the feed gas inlet and the first mixing chamber 7, used for feeding the feed gas To pressurize, the first mixing chamber 7 mixes the raw material gas and the exhaust gas in the shaft furnace 1 and then transfers it to the reformer 2; the reducing gas inlet 1-2 is connected to the raw material gas inlet 2-1; The reformer 2 is also provided with a first gas port 2...

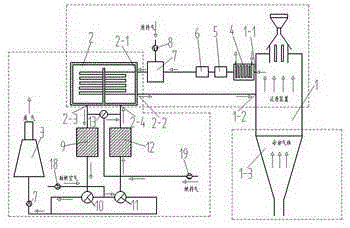

Embodiment 2

[0025] like figure 2 As shown, this embodiment is based on the technical solution of the first embodiment, and the following technical solution is added: between the first gas port 2-3 and the exhaust gas discharge device 3, a first regenerative heat exchanger is connected. Heater 9, a first reversing valve 10 is also provided between the first regenerative heat exchanger 9 and the exhaust gas discharge device 3; between the combustion air inlet and the second air port 2-4 A second reversing valve 11 and a second regenerative heat exchanger 12 are provided in sequence, and there is a pipeline communication between the first reversing valve 10, the second reversing valve 11 and the exhaust gas discharge device 3; A third reversing valve 13 is connected between the fuel gas inlet and the second gas port 2-4, and the third reversing valve 13, the first gas port 2-3 and the second gas port There is pipeline communication between 2-4.

[0026]The working process of this embodime...

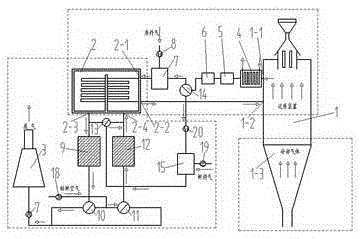

Embodiment 3

[0029] like image 3 As shown, this embodiment is based on the technical solution of the second embodiment, and the following technical solution is added: a fourth reversing valve 14 is also provided between the carbon dioxide absorption device 6 and the first mixing chamber 7, A second mixing chamber 15 is connected between the fourth reversing valve 14 and the fuel gas inlet, and a fifth pressurizer 20 is arranged between the fourth reversing valve 14 and the second mixing chamber 15 , the mixing chamber 15 mixes the gas passing through the reversing valve 14 with the fuel gas and then sends it to the reformer 2 .

[0030] The working process of this embodiment is: the pressurized combustion-supporting air and fuel gas are sent into the reformer 2 through the second gas port 2-4 for combustion to generate high temperature, and the raw material gas is passed into the reformer 2 for cracking reaction to generate High-temperature carbon monoxide and hydrogen (about 900 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com