Low-molybdenum high-titanium 590MPa-grade fire-retardant steel plate for building and preparation method of steel plate

A construction and refractory technology, applied in the direction of temperature control, to achieve the effect of low process cost, uniform and fine structure, and improved welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

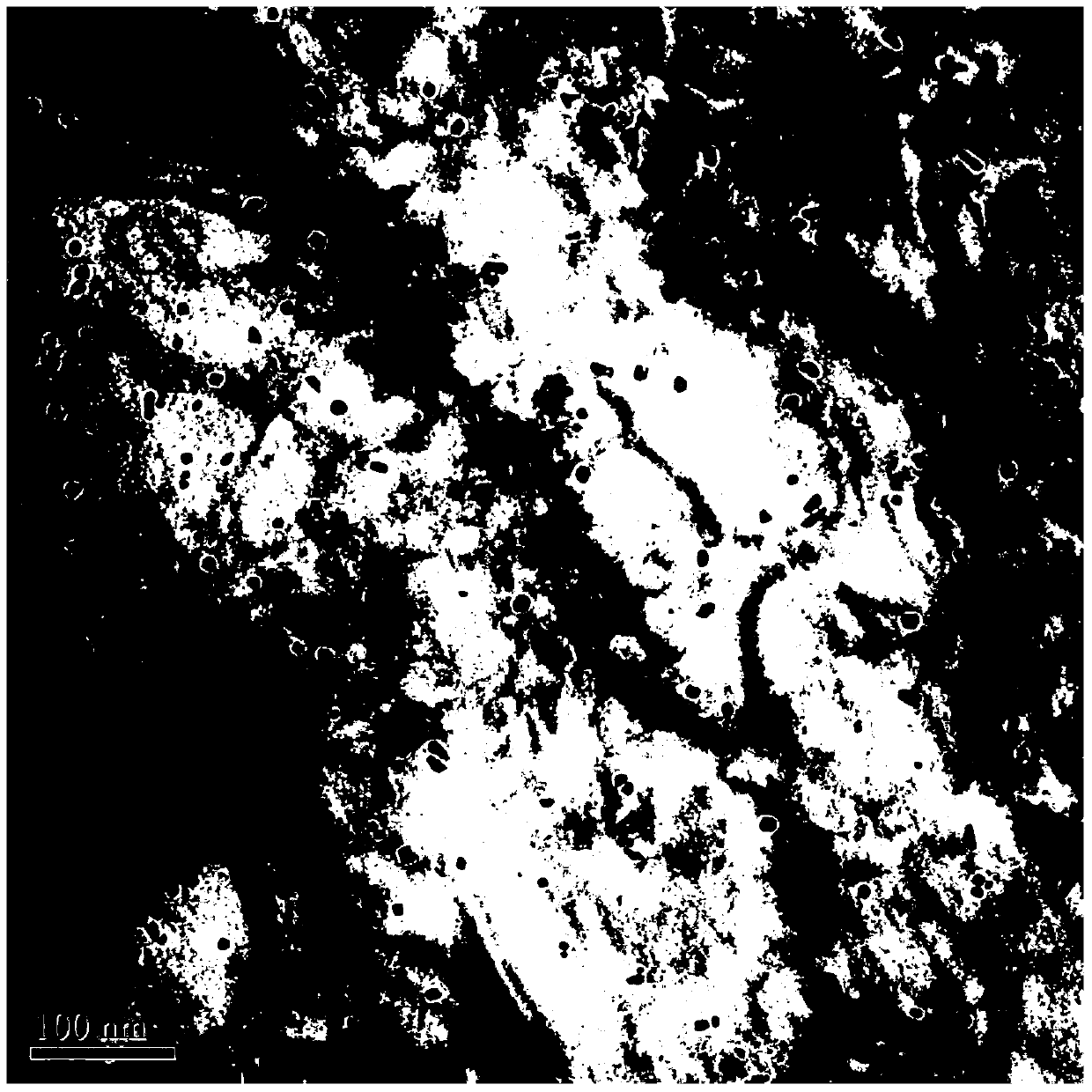

Image

Examples

Embodiment Construction

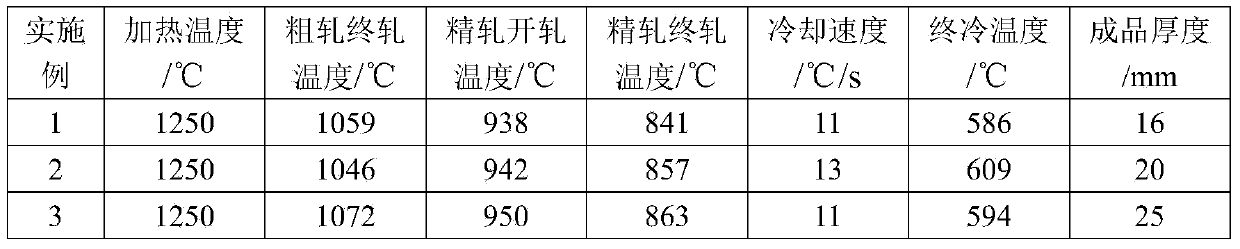

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and several embodiments, but are not limited thereto.

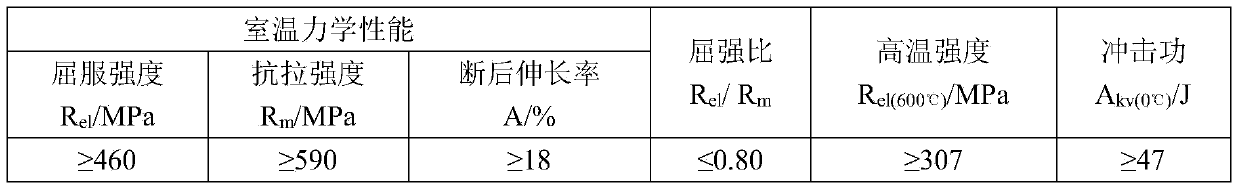

[0033]According to the chemical composition and smelting process requirements of the fire-resistant steel of the present invention, the chemical composition of the smelted steel is shown in Table 1, and the balance is Fe and unavoidable impurities.

[0034] The chemical composition (wt.%) of the embodiment of the present invention of table 1

[0035] Example

C

Si

mn

P

S

Al

Cr

Mo

Nb

Ti

O

1

0.06

0.23

0.78

0.009

0.0037

0.041

0.28

0.13

0.018

0.11

0.001

2

0.08

0.22

0.95

0.011

0.0042

0.038

0.32

0.12

0.023

0.08

0.002

3

0.09

0.27

0.82

0.012

0.0039

0.035

0.37

0.15

0.021

0.06

0.002

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com