Light steel structure anti-seismic house

A technology for light steel structure and earthquake-resistant houses, which is applied in building components, building structures, building types, etc., can solve the problem of integration of structure and energy saving, the lack of implementation plans for light steel structure houses, and the vast number of village and town houses. Difficult to apply etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0126] The present invention will be described in further detail below in conjunction with the accompanying drawings.

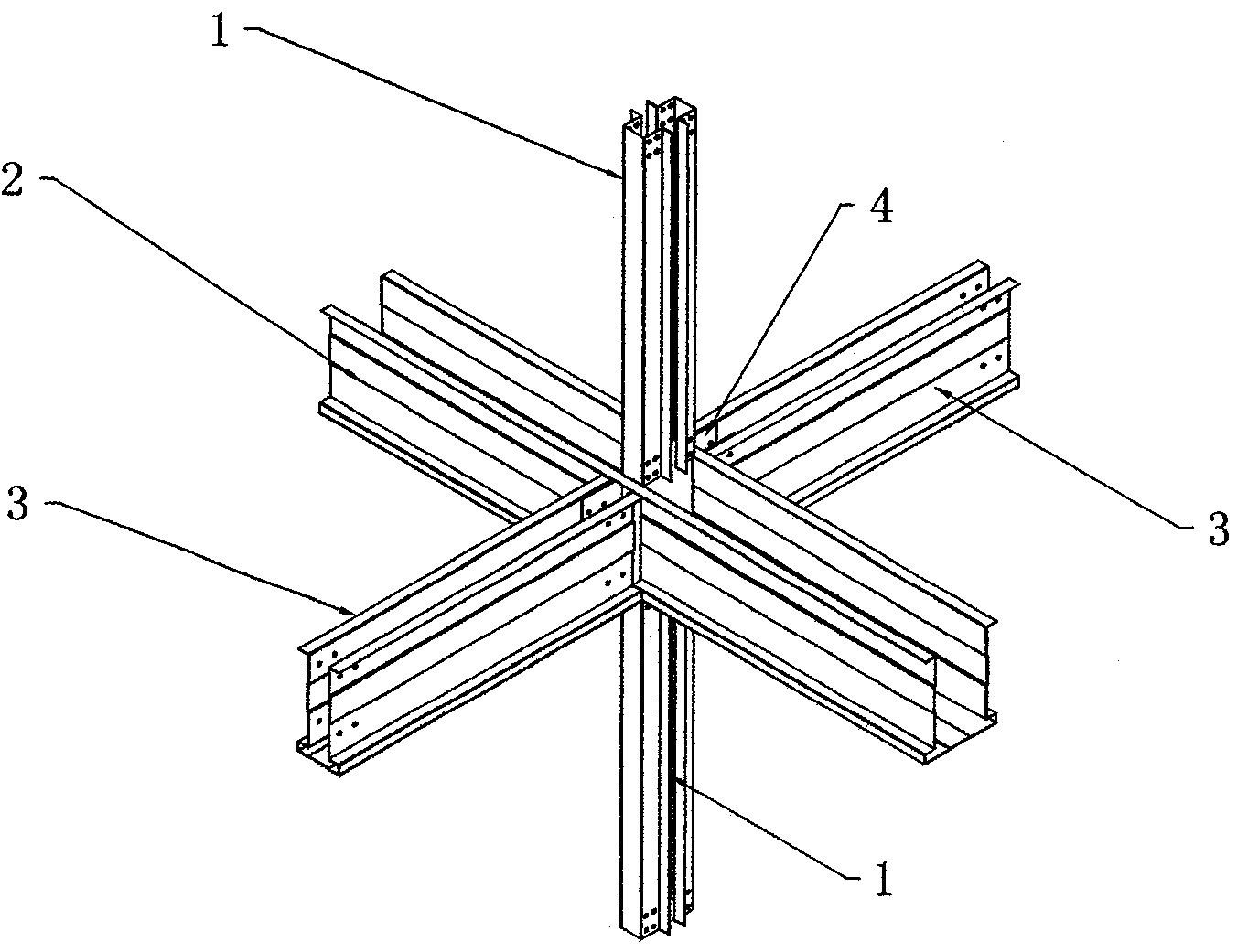

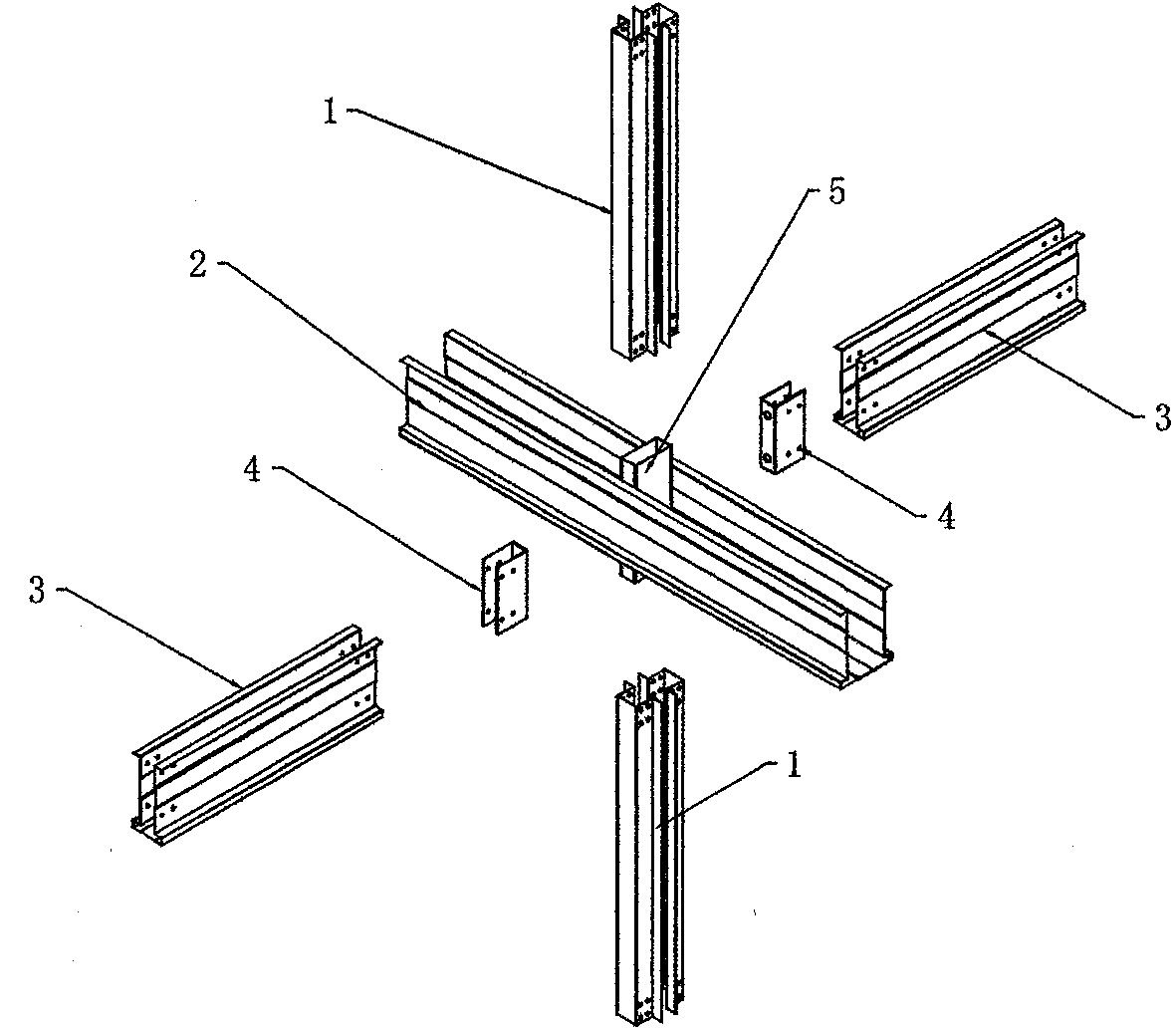

[0127] In the anti-seismic house with light steel structure according to the present invention, its wall adopts light steel keel as the wall structure system (wall structure load-bearing skeleton), and its floor adopts light steel keel as the floor structure system (floor structure load-bearing skeleton), wherein, Such as figure 1 , 2 Shown:

[0128] The floor structure system and the wall structure system share the main keel 2, and the main keel 2 is usually arranged at least along the wall. Set the main keel 2 in the area without walls,

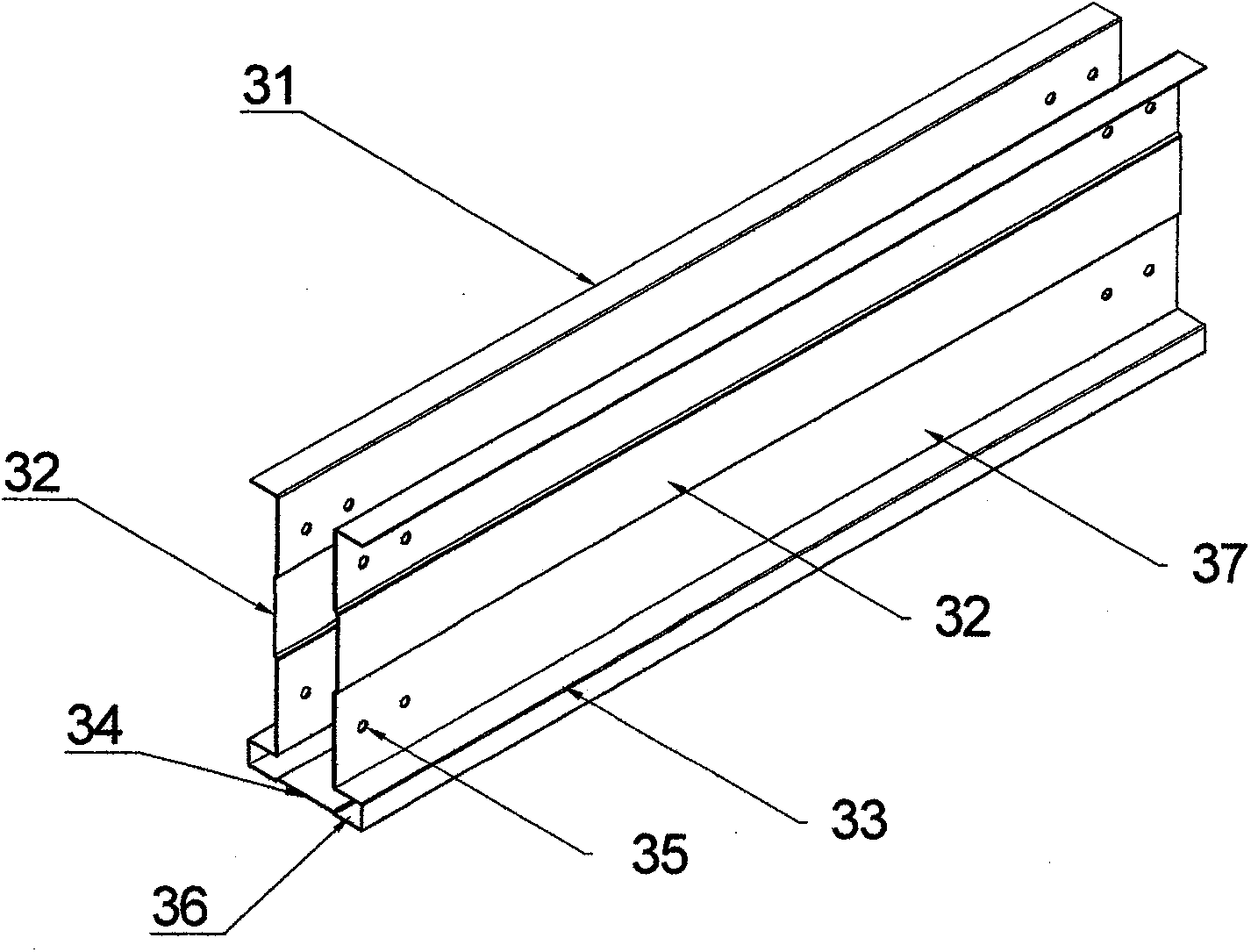

[0129]The floor structure system also includes a sub-keel 3, the sub-keel 3 is arranged between two adjacent main keels 2, the sub-keel 3 is vertically connected to the main keel 2, and the sub-keels 3 are parallel to each other, or between the sub-keels 3 Depending on the size of the building area of each area in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com