Heat insulation method for bottle washing machine or sterilization machine in beer or beverage industry

A bottle washing machine and sterilizing machine technology, applied in chemical instruments and methods, devices for coating liquid on surfaces, coatings, etc. beautiful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (1) LEADER TM The production process of industrial heat insulation coils is as follows:

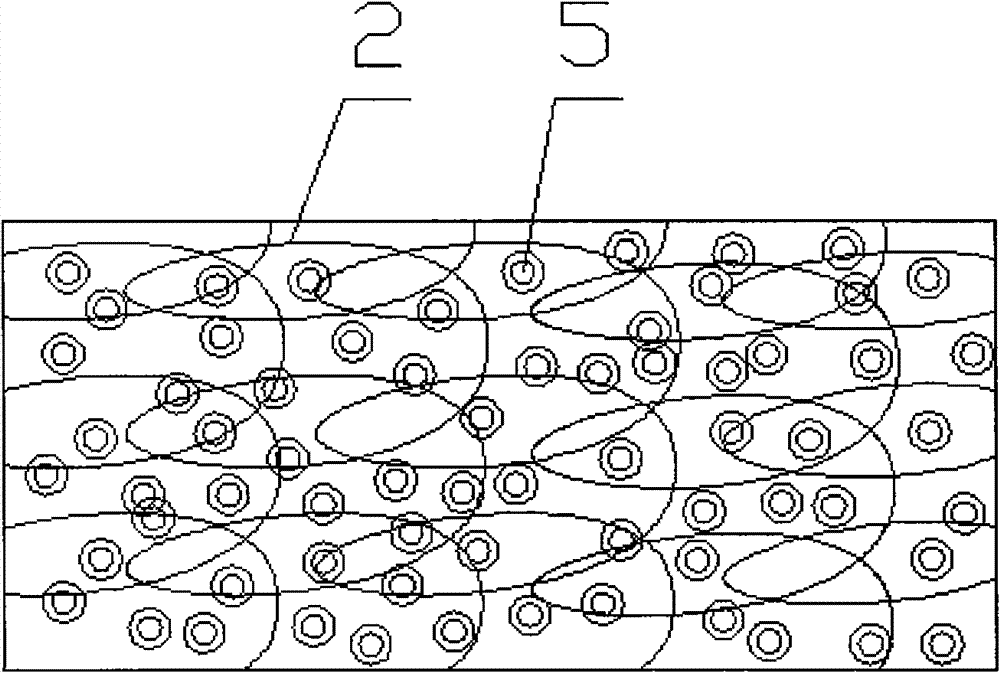

[0058] A. Make the slurry: first, add silica silica sol, high temperature resistant inorganic ceramic hollow microspheres with a pore size of 50-60 nanometers, deionized water and diluent (acetonitrile) in a weight ratio of 1:2:1.5:0.5 to disperse Fully disperse in the reactor to make a slurry.

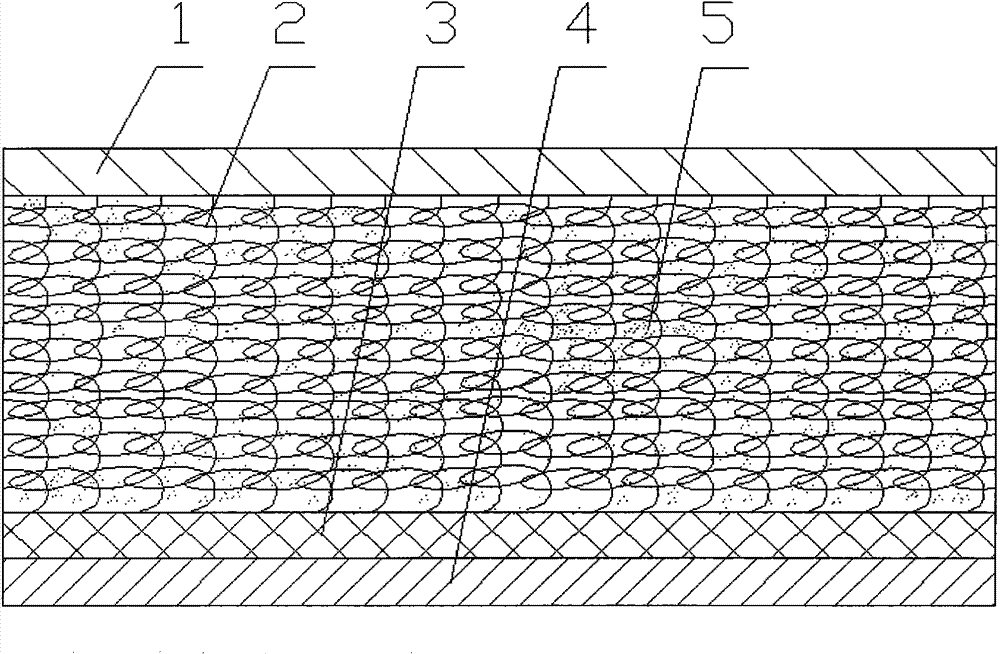

[0059] B. Coil base material sizing: inject the slurry into the slurry tank, and intrude the aluminum silicate needle-punched fiber coil base material with a thickness of 2.5mm to 3.0mm into the sizing tank, and at the same time use the diaphragm pump to circulate the slurry and Spray it onto the aluminum silicate needle-punched fiber substrate through a nozzle to ensure that 5kg of slurry is attached to each square meter of coiled material. Cut the sized aluminum silicate needle-punched fiber substrate into a length of 15M, and tightly roll it on a stainless steel target frame with a di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com