Industrial sewage heat energy replacement device

A technology for industrial sewage and heat energy, applied in heat exchange equipment, indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of no heat energy replacement device and method, corrosion and scaling of pipelines, waste of heat energy, etc., and achieve considerable benefits. The effect of saving electric energy and fuel, and efficiently transferring heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

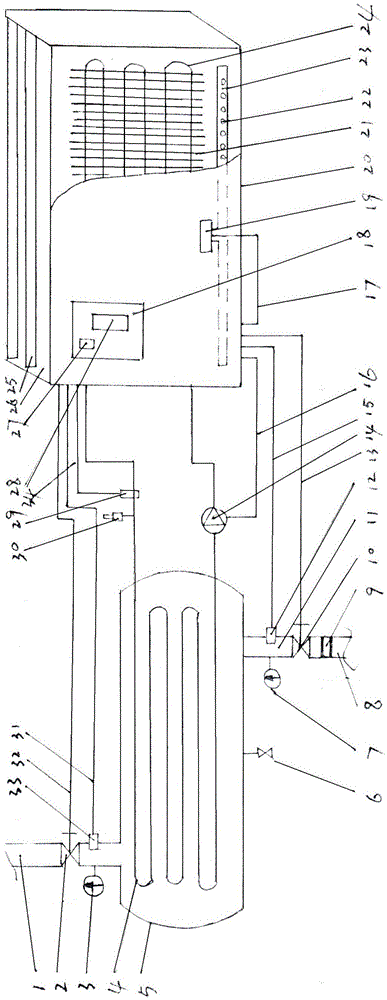

[0024] see figure 1 , an industrial sewage heat energy replacement device is mainly composed of a heat storage tank, a serpentine heat exchange tube, a temperature sensor, a heat pump, a heat dissipation box, a heat dissipation pipe, an energy analysis module and a supporting safety protection system.

[0025] The heat storage tank 5 is a cylindrical pressure vessel with a hemispherical shell sealed at both ends, and an upper pipe 11 is connected to one end of the bottom, and the pipe wall of the upper pipe 11 is connected with a pressure gauge B7 through a pressure gauge joint, and the temperature sensor A12 is directly inserted On the pipe wall, the temperature signal of the temperature sensor A12 is transmitted to the energy analysis module 18 through the temperature sensor A signal line 15 . The lower end of the upstream pipe 11 is connected with the upstream electric valve 10 , and the upstream electric valve is operated by the touch operation screen 27 of the energy anal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com