Method for measuring particle size distribution and content of globular oxide inclusions in steel

A size distribution and oxide technology, applied in particle size analysis, measuring devices, particle and sedimentation analysis, etc., can solve the problems that it is difficult to analyze small samples, it is not suitable for furnace analysis, and the collection sample capacity is small, etc., to achieve The effect of fast analysis speed, improved analysis accuracy, and small sample volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

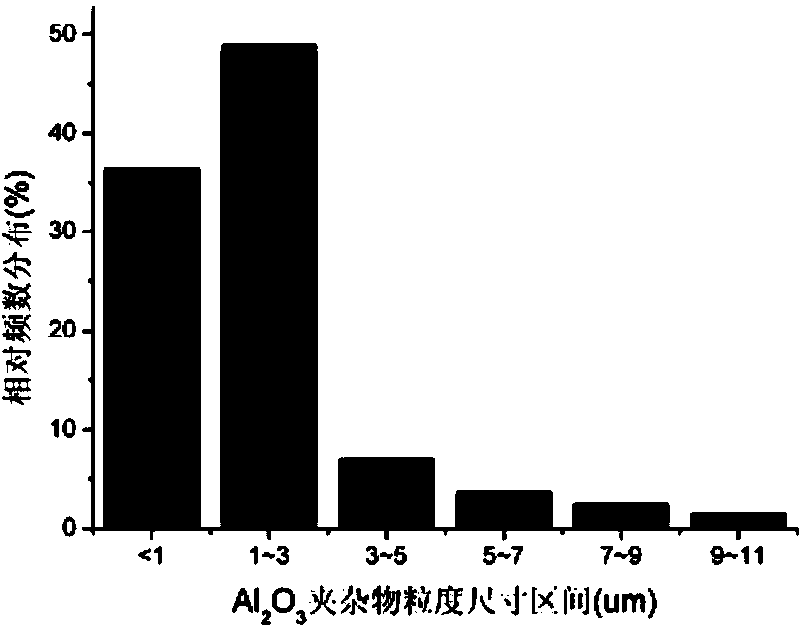

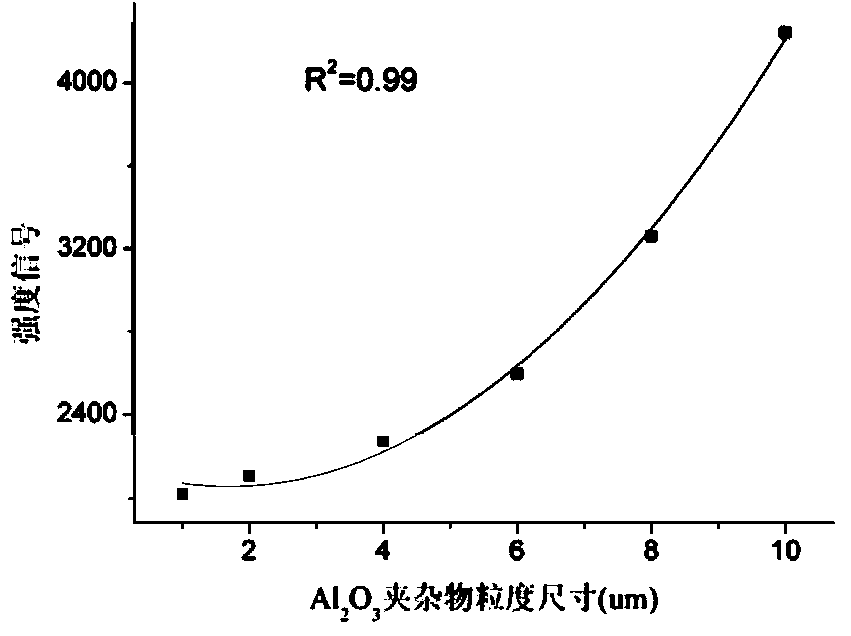

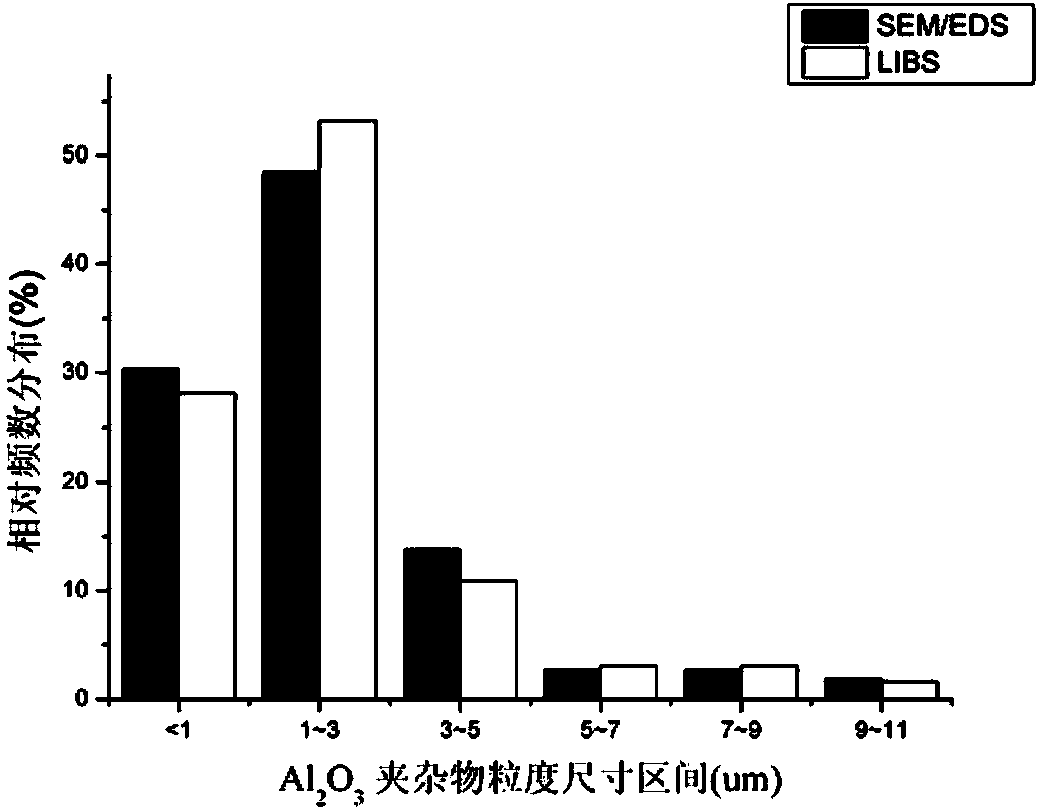

[0049] Example (Al in the grade GCr15 bearing steel 2 O 3 Characterization of particle size distribution and content of inclusions as an example)

[0050] In this example, the laser-induced breakdown spectroscopy was used to compare the Al content of the grade GCr15 bearing steel. 2 O 3 The characterization of the particle size distribution and content of inclusions is described.

[0051] Al 2 O 3 Characterization of Inclusion Particle Size Distribution

[0052] a) Sample preparation: The grade GCr15 bearing steel sample is cut according to the size of the sample box of the laser-induced breakdown spectrometer, and the surface of the cut sample is polished by rough polishing and fine polishing;

[0053] b) Determination of the marked area of the sample: use laser-induced breakdown spectroscopy to make 6 square marked areas on the polished sample surface, and the size of the marked area is 3 × 3 mm 2 ;

[0054] c) Analysis of Al by SEM and EDS 2 O 3 Relative particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com