A device and method for removing uranium hexafluoride contamination from a measuring sensor

A technology for measuring sensors and uranium hexafluoride, used in radioactive purification, nuclear engineering, etc., can solve the problems of out-of-control measurement standards, adverse effects on the environment, and expansion of the scope of influence of operators, so as to reduce the possibility of contamination and reduce The generation of waste liquid, the effect of avoiding adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

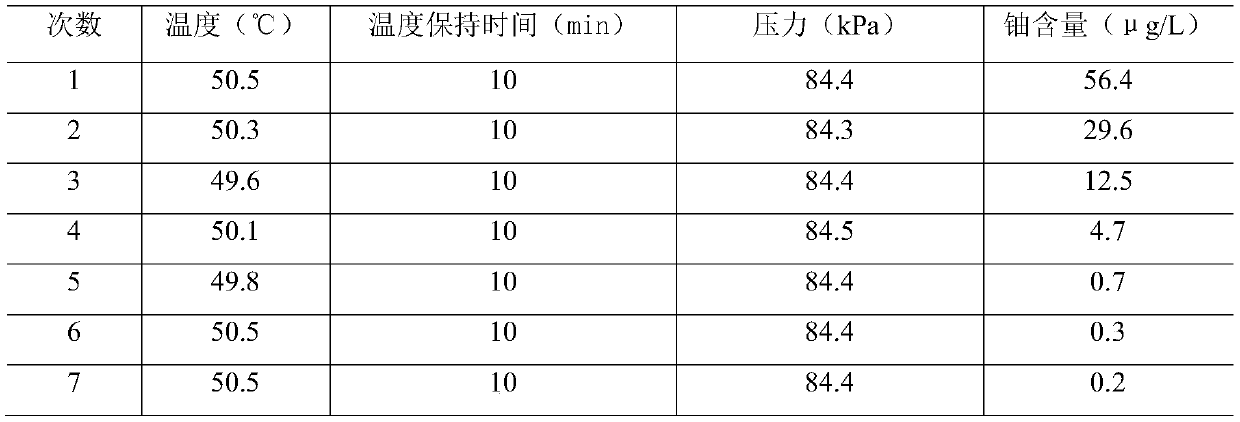

Examples

Embodiment Construction

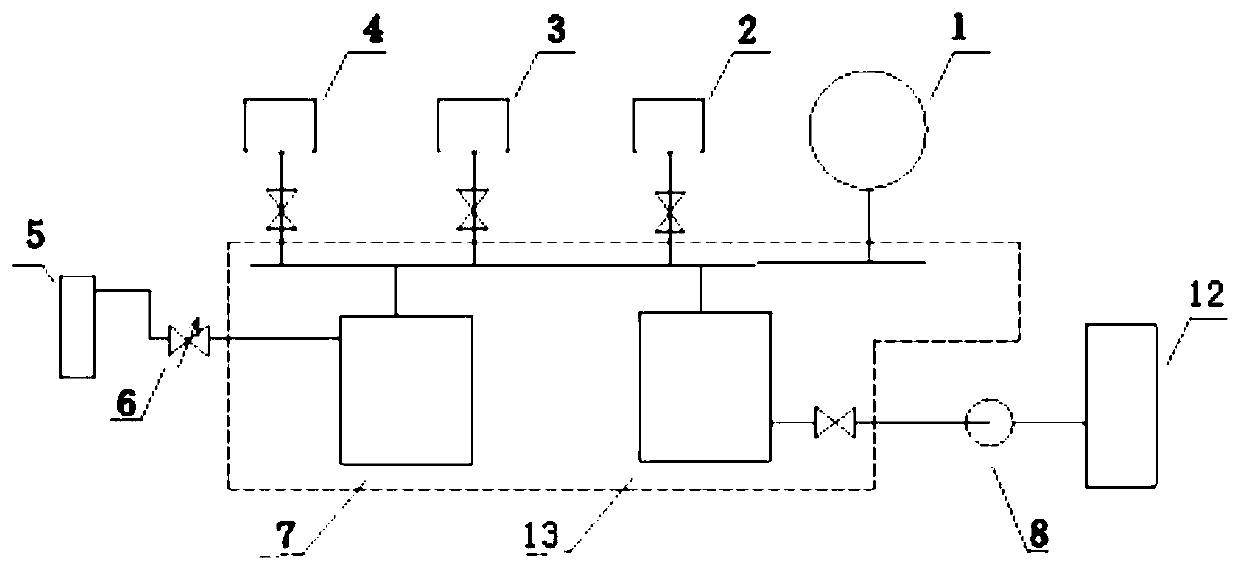

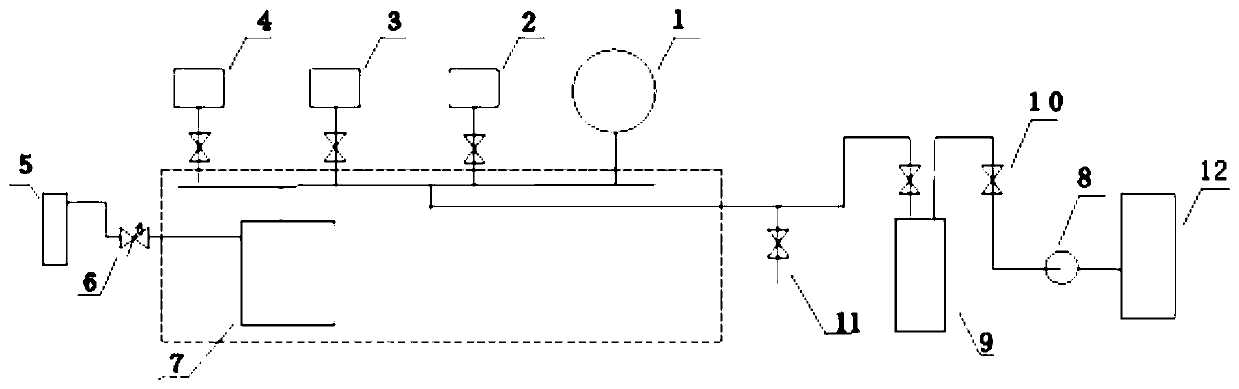

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0043] A device for removing uranium hexafluoride contamination from measuring sensors, capable of simultaneously cleaning three or less than three uranium hexafluoride measuring sensors, the three uranium hexafluoride measuring sensors are respectively set as a sensor to be decontaminated 2. The second sensor to be decontaminated 3 and the third sensor to be decontaminated 4, the device includes a main pipe, a branch pipe, a connecting pipe, a pressure monitoring and measuring instrument 1, a nitrogen cylinder 5, a pressure reducing valve 6 and a buffer tank 7.

[0044] The pressure monitoring and measuring instrument 1 is connected to the main pipe, and three branch points are successively arranged on the main pipe at the rear of the pressure monitoring and measuring instrument 1, each of which leads to a connecting pipe through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com