Electron beam acceleration power device and control method

A technology of power supply control and electron beam, which is applied in the direction of control/regulation system, output power conversion device, electrical components, etc. It can solve the problem of small capacitance value of high-voltage capacitor, ineffective filtering effect of inductance, and reduced ability to eliminate peak and sag voltage And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

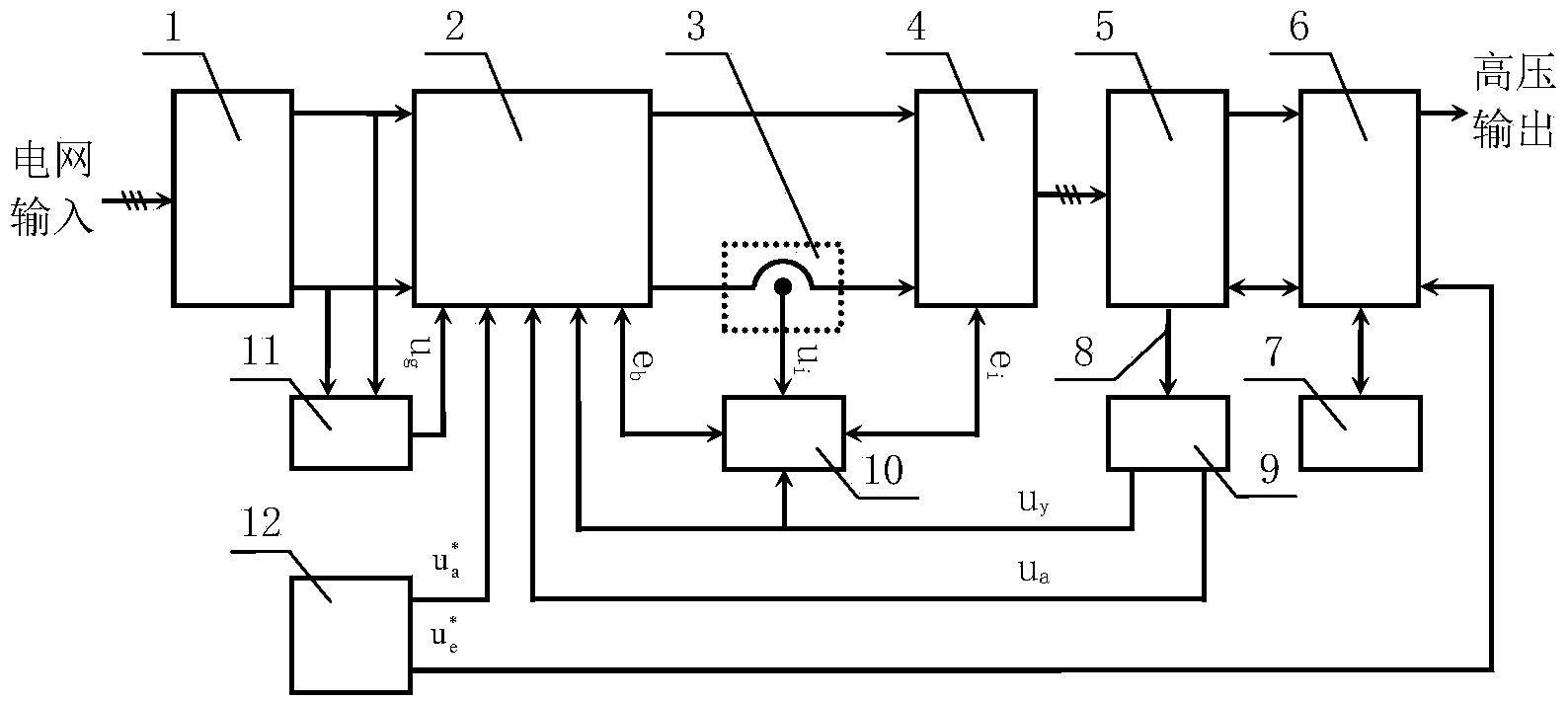

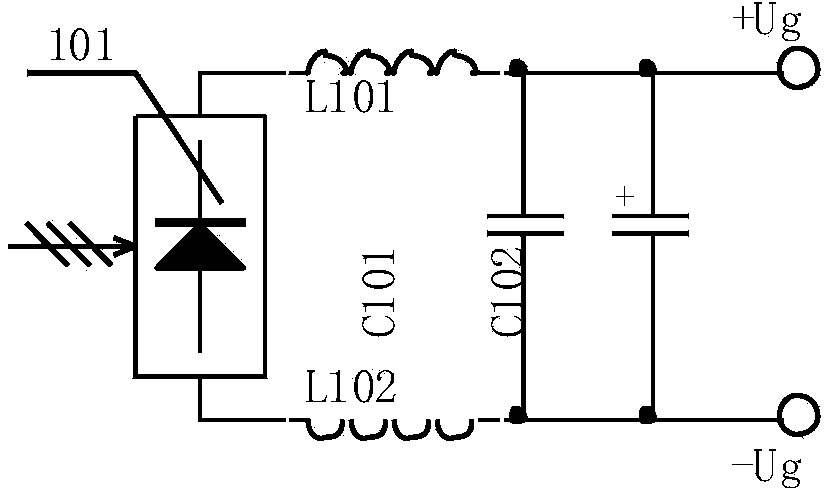

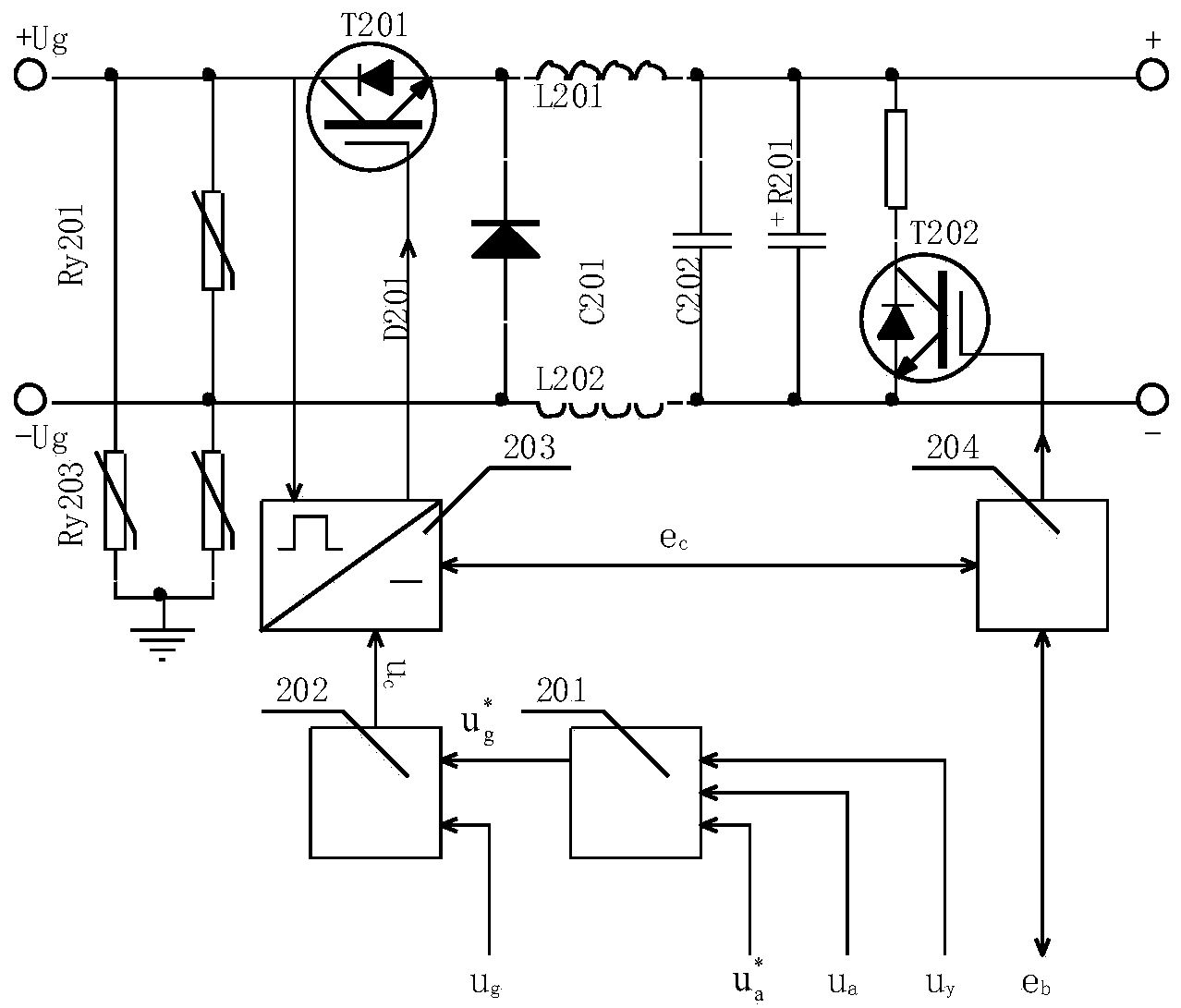

[0065] Such as figure 1 As shown, an electron beam accelerated power supply control method adopts a double closed-loop voltage stabilization control method. The pre-stage voltage stabilization system uses a DC-DC converter 2 for voltage regulation, a three-phase rectangular wave inverter for 4 inverters, and a multi-phase rectangular wave inverter. Wave high-voltage AC rectification and filtering, parallel voltage stabilization at the output of high-voltage stabilizing components, comprehensive feedback of sampling signals for outputting high-voltage and stabilizing component currents, and low-voltage power supply DC feed-forward compensation to suppress ripples. , Negative feedback control of output voltage samplin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com