Method for removing bitterness of linseed oil by enzymatic process

A linseed oil removal technology, applied in the direction of edible oil/fat, food science, application, etc., can solve the problems of lack of market competitiveness of products, high cost of bitterness removal, etc., and achieve easy promotion, low environmental requirements, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

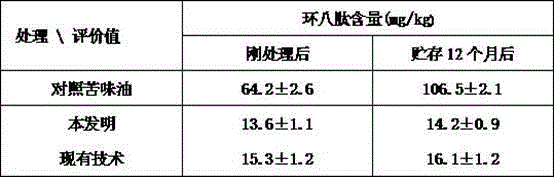

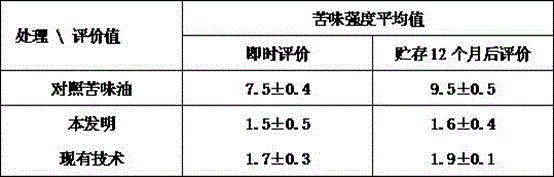

Examples

Embodiment 1

[0021] First, take 1000ml of bitter linseed oil and heat it to 50°C; then take 1g of neutral protease with an enzyme activity of 200,000 u / g and dissolve it in 8ml of drinking water at 50°C, and adjust the pH value of the solution to 7; then prepare The neutral protease solution was added to 1000ml of hot oil while stirring, and the stirring was continued for 3 hours, then the oil was heated to 85°C to inactivate the enzyme for 30 minutes, the oil and water were separated by centrifugation, and finally the centrifuged oil was dehydrated to obtain Debittered flax oil. After accounting, the reagent cost for debittering treatment is 0.1 yuan / kg linseed oil.

Embodiment 2

[0023] Take 1000ml of freshly squeezed linseed oil and heat it to 55°C; then take 0.1g of neutral protease with an enzyme activity of 200,000 u / g and dissolve it in 2ml of drinking water at 55°C, and adjust the pH value of the solution to 7.2; Add the prepared neutral protease solution into 1000ml of hot oil while stirring, keep stirring for 4 hours, then raise the temperature of the oil to 80°C to inactivate the enzyme for 30 minutes, centrifuge the oil and water, and finally dehydrate the centrifuged oil, That is to get off the bitterness of linseed oil.

Embodiment 3

[0025] Take 1000ml of bitter linseed oil and heat it to 40°C; then take 2g of neutral protease with an enzyme activity of 200,000 u / g and dissolve it in 20ml of drinking water at 48°C, and adjust the pH value of the solution to 7.2; then prepare the Add the neutral protease solution into 1000ml hot oil while stirring, keep stirring for 2 hours, then raise the temperature of the oil to 82°C to inactivate the enzyme for 30 minutes, centrifuge the oil and water, and finally dehydrate the centrifuged oil to obtain dehydration Debitter flax oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com