Anti-transport stress composite preparation for beef cattle

A technology of anti-transportation stress and compound preparations, which is applied in the field of animal husbandry, can solve the problems of affecting meat quality, decreased immunity of beef cattle, and large stress response, and achieve the effect of suppressing anxiety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

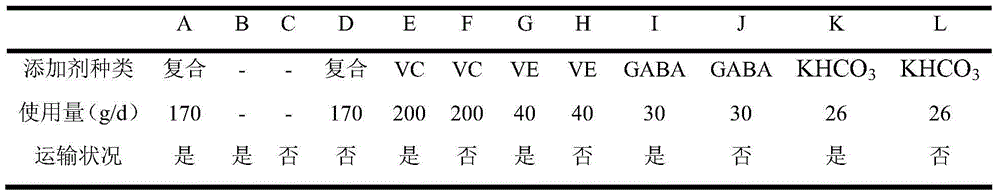

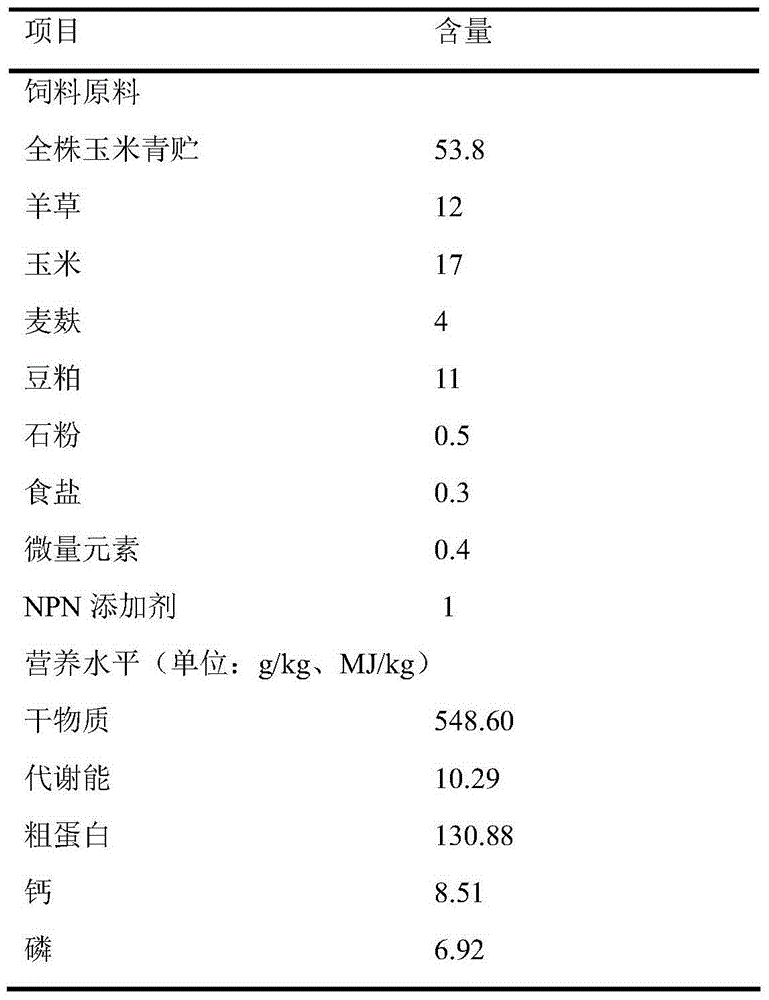

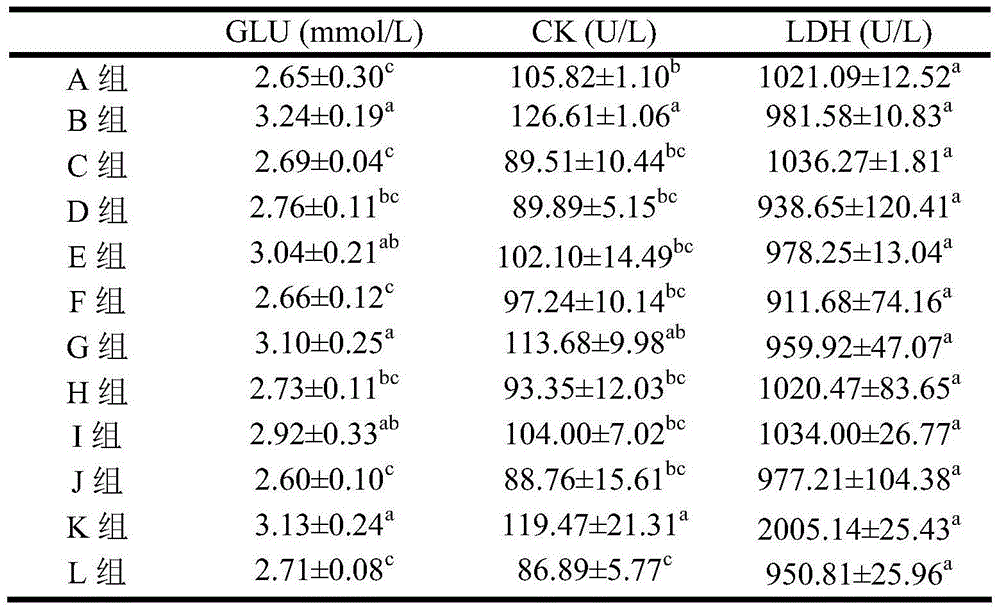

Method used

Image

Examples

Embodiment 1

[0023] Take 15g of vitamin C phosphate, 2g of ethyl cellulose, 82.6g of cyclohexane, and 0.4g of polyethylene, adopt the rumen passing technology, and go through the conventional methods of mixing, stirring, cooling, initial encapsulation, capsule wall solidification, filtration, and spray drying. The step is coating vitamin C phosphate into vitamin C sulfate microcapsules. Take 35g of vitamin E, 0.3g of sucrose ester (S1570), 43g of gum (GUM2000), and 21.6g of sucrose, and use the rumen-passing technology to coat vitamin E into vitamin E microcapsules through high-pressure homogenization and spray drying. Take 45g of γ-aminobutyric acid and 55g of maltodextrin, and use the rumen-passing technique to coat γ-aminobutyric acid into Gamma-aminobutyric acid microcapsules. Take KHCO 3 55g, ethyl cellulose 45g, using the rumen technology, through conventional steps such as mixing, stirring, cooling, initial encapsulation, capsule wall solidification, filtration, spray drying, etc....

Embodiment 2

[0026] Take 25g of Vitamin C Phosphate, 1.9g of Ethylcellulose, 72.8g of Cyclohexane, and 0.34g of Polyethylene, and use rumen-passing technology, and go through mixing, stirring, cooling, initial encapsulation, capsule wall solidification, filtration, spray drying, etc. In conventional steps, vitamin C phosphate is coated into vitamin C sulfate microcapsules. Take 30g of vitamin E, 0.35g of sucrose ester (S1570), 46.45g of pure gum (GUM2000), and 23.2g of sucrose, and use rumen-passing technology to coat vitamin E into vitamin E microcapsules through steps such as high-pressure homogenization and spray drying. Take 45g of γ-aminobutyric acid and 55g of maltodextrin, and use the rumen-passing technique to coat γ-aminobutyric acid into Gamma-aminobutyric acid microcapsules. Take KHCO 3 50g, ethyl cellulose 50g, using the rumen technology, through conventional steps such as mixing, stirring, cooling, initial encapsulation, capsule wall solidification, filtration, spray drying,...

Embodiment 3

[0029] Take 20g of vitamin C phosphate, 2g of ethyl cellulose, 77.64g of cyclohexane, and 0.36g of polyethylene, adopt the rumen-passing technology, and go through conventional methods such as mixing, stirring, cooling, initial encapsulation, capsule wall solidification, filtration, and spray drying. The step is coating vitamin C phosphate into vitamin C sulfate microcapsules. Take 25g of vitamin E, 0.37g of sucrose ester (S1570), 49.75g of pure gum (GUM2000), and 24.88g of sucrose, and use rumen-passing technology to coat vitamin E into vitamin E microcapsules through high-pressure homogenization and spray drying. Take 40g of γ-aminobutyric acid and 60g of maltodextrin, and use rumen-passing technology to coat γ-aminobutyric acid into Gamma-aminobutyric acid microcapsules. Take KHCO 3 55g, ethyl cellulose 45g, using the rumen technology, through conventional steps such as mixing, stirring, cooling, initial encapsulation, capsule wall solidification, filtration, spray drying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com