A method and device for absorbing hydrazine gas in a closed space

A gas absorption and confined space technology, which is applied in separation methods, chemical instruments and methods, and dispersed particle separation, etc., can solve the problems of increasing the gas-liquid contact area, large size of the device, and complicated operation, so as to increase the gas-liquid contact area, Small structure and the effect of increasing adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

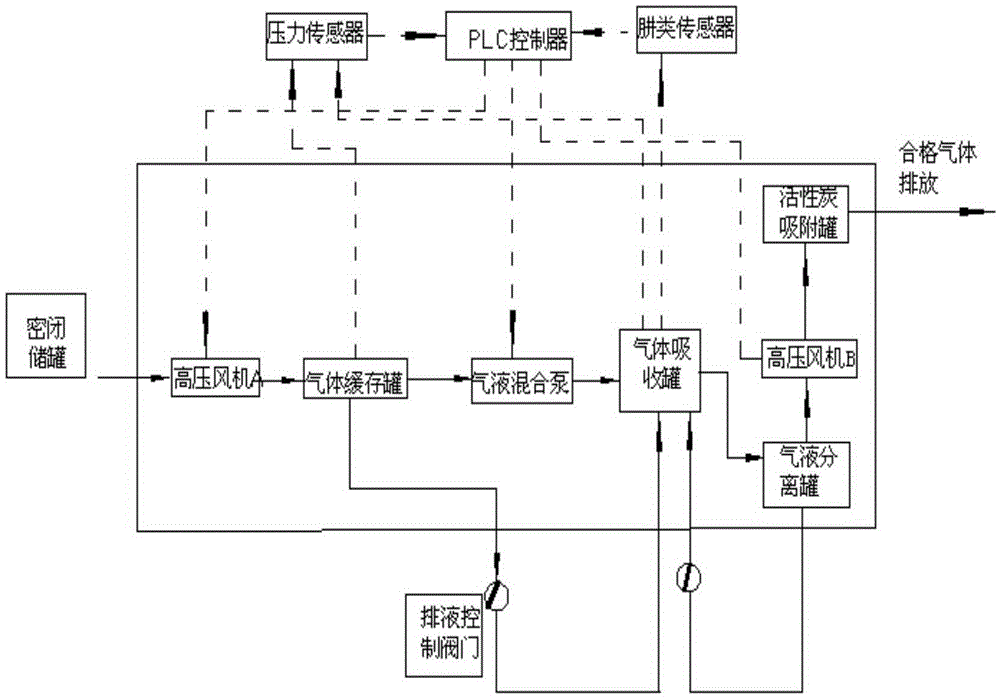

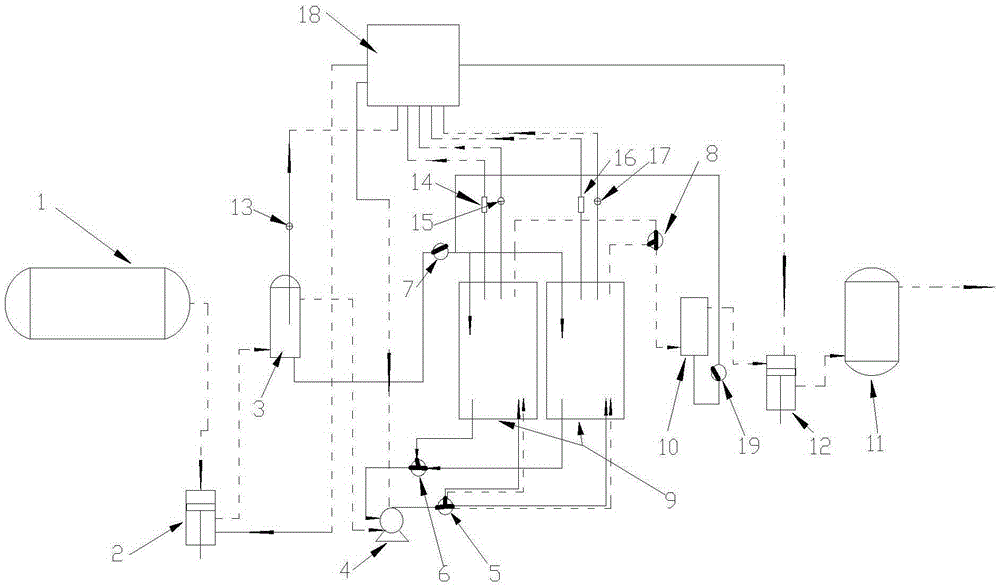

[0043] A method for absorbing hydrazine gas in a confined space, please refer to figure 1 ; includes the following steps:

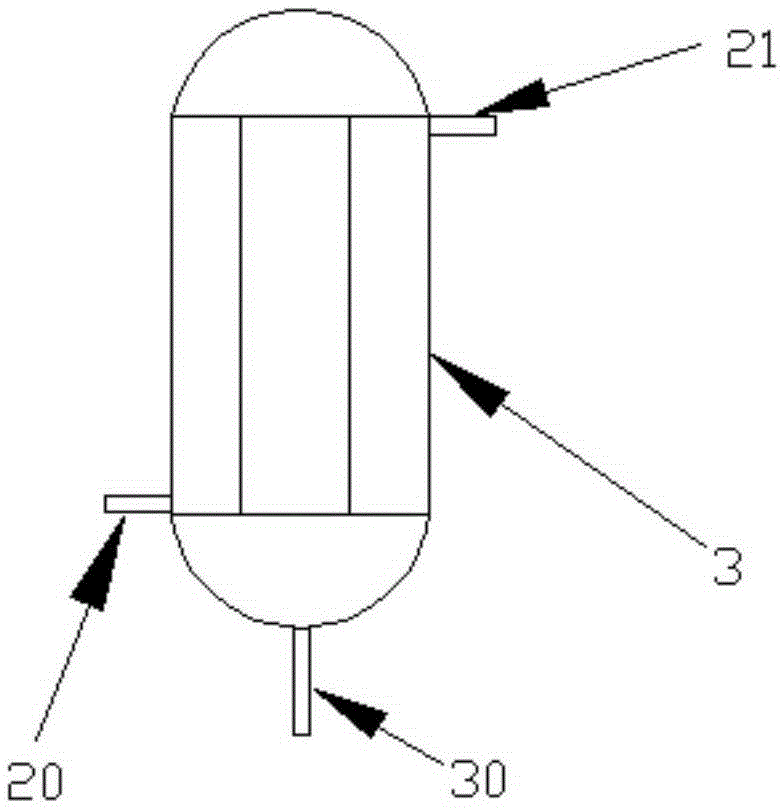

[0044] Step S100, using the high-pressure blower A2 to blow the hydrazine gas in the airtight storage tank 1 into the gas buffer tank 3, the gas buffer tank 3 is provided with a pressure sensor 13 to control the hydrazine gas to be kept within the pressure range of 0.11-0.13 MPa , the pressure sensor 13 is connected to the PLC controller 18; the gas buffer tank 3 is a stainless steel tank, or other materials, but the strength is greater! Security must be high! The height to diameter ratio of the gas buffer tank 3 is generally designed to be 2:1 to 4:1, preferably 3:1; the volume of the gas buffer tank 3 is controlled at 0.5m 3 ~0.8m 3 .

[0045] Step S200, using the gas-liquid mixed gas in the gas buffer tank 3 in step S100, using the gas-liquid mixing pump 4 to control the ratio of the flow rate of the absorption liquid in the gas absorption tank 9 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com