Method for removing nitrogen oxides in industrial waste gas

A technology of nitrogen oxides and industrial waste gas, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of great influence on the effectiveness of urea reaction and secondary pollution, and achieve easy management, clean production, The effect of easy response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

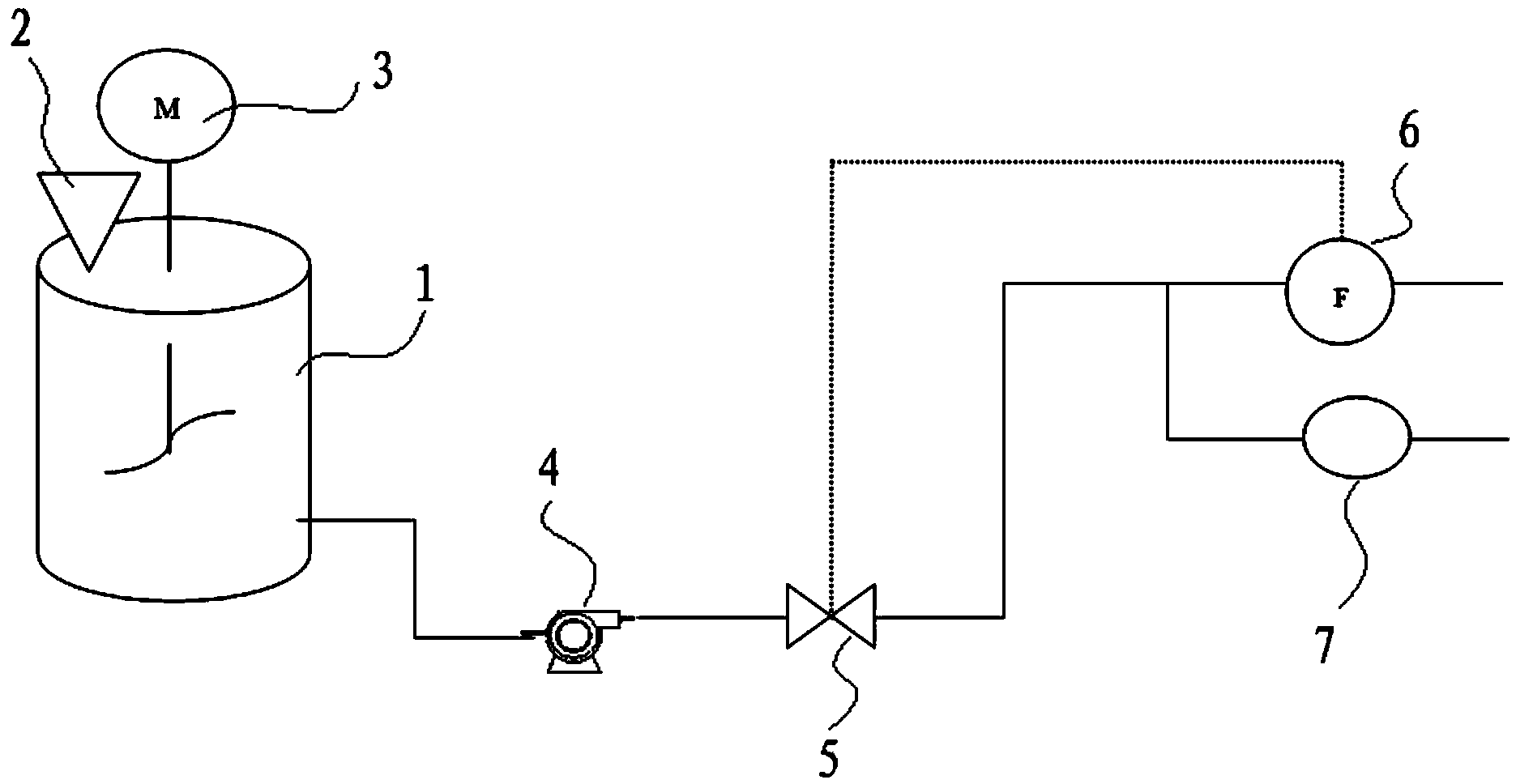

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] see figure 1 , a method for removing nitrogen oxides in industrial waste gas according to the present invention adopts a special device for removing nitrogen oxides in industrial waste gas. 5. Flow meter 6 and exhaust gas generator;

[0023] A kind of method of removing nitrogen oxides in industrial waste gas of the present invention adopts ammonium bicarbonate as reactant and comprises the following steps:

[0024] In the step of preparing the solution, solid ammonium bicarbonate is added to the mixing tank 1 filled with industrial water through the hopper 2, and mixed with industrial water under the agitation of the mixer 3 of the mixing tank 1 to generate a 20% concentration of ammonium bicarbonate solution;

[0025] In the delivery step, the ammonium bicarbonate solution is first delivered to the feed point 7 by the delivery pump 4, and then the flow meter 6 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com