Dual-metal thrust sliding bearing blank preparation method and tooling used by same

A technology of sliding bearings and bimetals, which is applied in the field of centrifugal casting of bimetallic thrust sliding bearing blanks, can solve the problems of difficult control of the process and difficulty in meeting the performance requirements, and achieve the advantages of simple operation, long service life and good bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

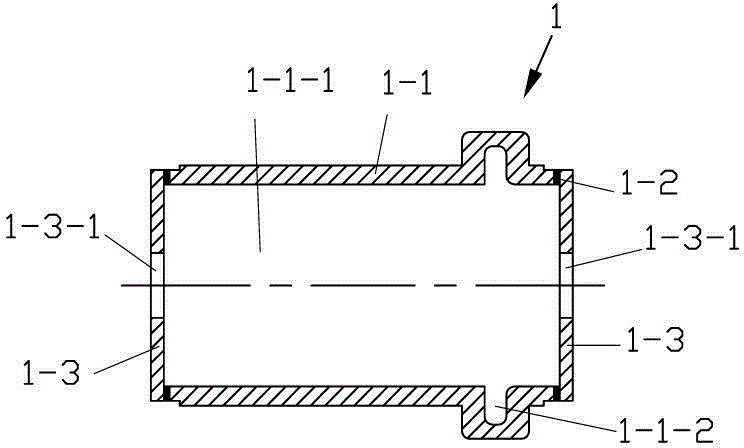

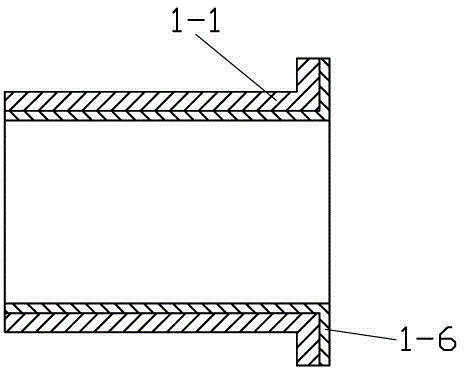

[0033] Such as figure 1 As shown, a mold 1 for preparing a bimetallic thrust sliding bearing blank of the present invention includes a steel billet 1-1 and a first asbestos board 1-3, and the steel billet 1-1 has an inner hole 1-1-1 and The annular groove 1-1-2, the annular groove 1-1-2 is arranged on the hole wall of the inner hole 1-1-1, the inner hole 1-1-1 communicates with the annular groove 1-1-2, the Both ends of the steel billet 1-1 are adhered with a corresponding first asbestos board 1-3 through a high temperature resistant adhesive 1-2, and the first asbestos board 1-3 has a central hole 1-3-1, and the second A central hole 1-3-1 of an asbestos board 1-3 communicates with an inner hole 1-1-1 of a billet 1-1.

[0034] The groove 1-1-2 is U-shaped, and one side of the U-shaped mouth is connected with the axial direction of the steel billet 1-1 by a circular arc, which is convenient for slag removal. The steel billet 1-1 needs to be treated with oil removal, rust remo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com