Solar distilling device and preparation method thereof

A distillation device and solar energy technology, applied in the field of solar energy products, can solve the problems of reducing the intensity of sunlight reaching the absorption layer, reducing the heat absorption efficiency of the heat absorption layer, dense water droplets, etc., achieving continuous and efficient distillation work, reducing scattering loss, and reducing contact. corner effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

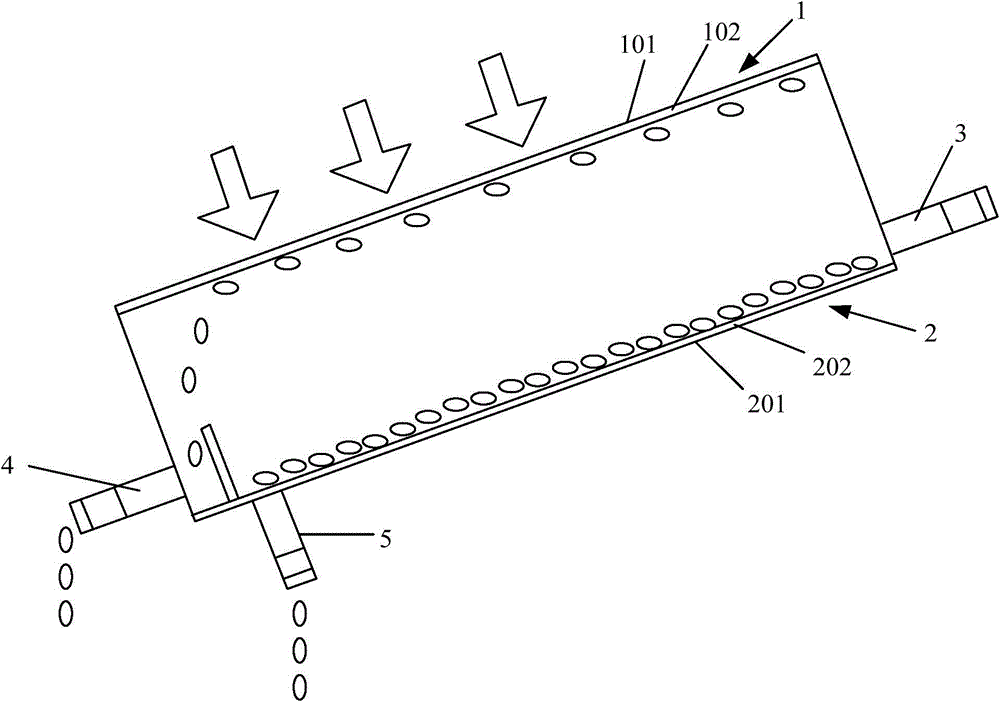

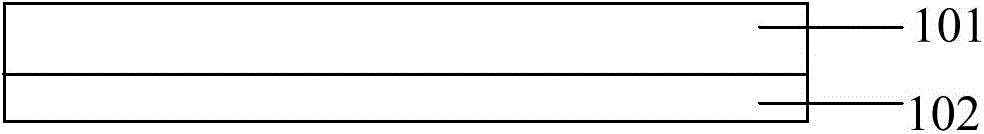

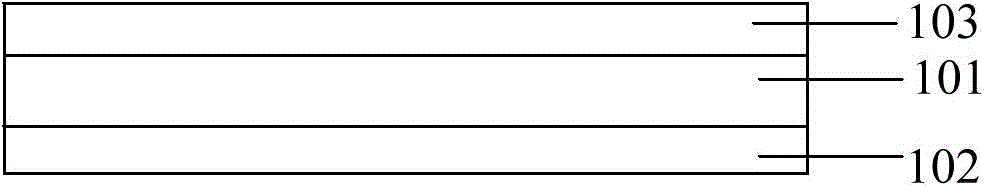

[0029] refer to figure 1 As shown, in order to increase the yield of distilled water and reduce the scaling problem of the heat absorbing layer, the present invention provides a solar distillation device for preparing distilled water, which includes an upper surface structure 1, a lower surface structure 2, and a raw water inlet 3. The distilled water outlet 4 and the sewage outlet 5, the upper surface structure 1 and the lower surface structure 2 enclose a closed storage chamber 6, wherein the upper surface structure 1 is coated with a hydrophilic coating, and the lower surface structure The surface structure 2 is coated with a hydrophobic coating, the sewage flows in from the raw water inlet 3, sunlight shines through the upper surface structure 1, and the water in the storage chamber 6 evaporates to the hydrophilic coating on the upper surface structure 1 to form a water film Finally, the distilled water flows out from the outlet 4, and the sewage layer is absorbed by the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap