Metallurgical industry cold rolling acid wastewater treatment system device and process thereof

A technology for acidic wastewater and metallurgical industry. It is applied in the fields of metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can solve the problem of short life cycle of equipment system, failure to directly meet discharge standards, frequent maintenance, etc. problems, to achieve the advantages of PLC automatic control, continuous operation of devices, and recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The metallurgical industry cold-rolling acid wastewater treatment system device and the process method thereof of the present invention are realized in this way, and will be described in detail below in conjunction with the accompanying drawings.

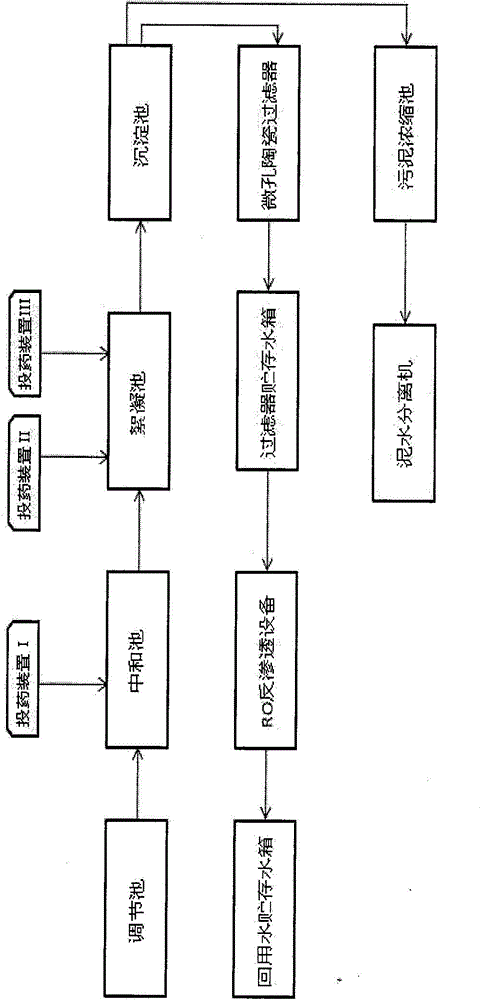

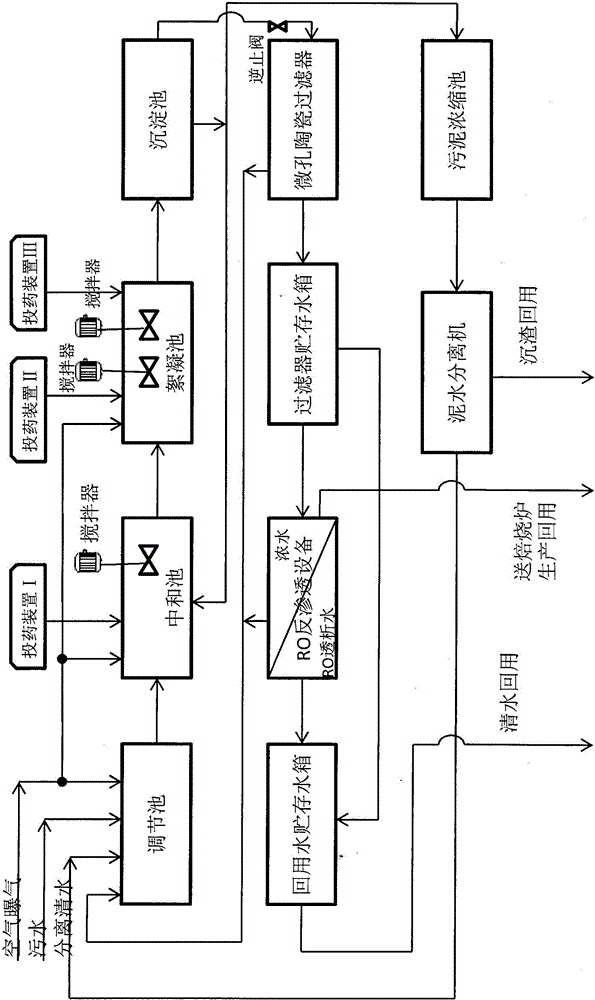

[0022] See figure 1 , the metallurgical industry cold-rolled acid wastewater treatment system device of the present invention is composed of: regulating pool, neutralization pool, dosing device I, dosing device II, dosing device III, flocculation tank, sedimentation tank, cleaning and filtering synchronous operation of fully automatic micro Pore ceramic filter, filter storage tank, RO reverse osmosis equipment, reuse water storage tank, sludge thickening tank and mud-water separator, regulating tank and dosing device I are respectively connected to neutralization tank, neutralization tank and dosing device II and dosing device III are connected to the flocculation tank, the flocculation tank is connected to the sedimentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com