Multi-proof thermosensitive paper free of top coating and manufacture process thereof

A production process and heat-proof technology, applied in papermaking, coating, paper coating, etc., can solve the problems of being unsuitable for low production costs, and achieve the effects of stable properties, reduced coating processes, and strong weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

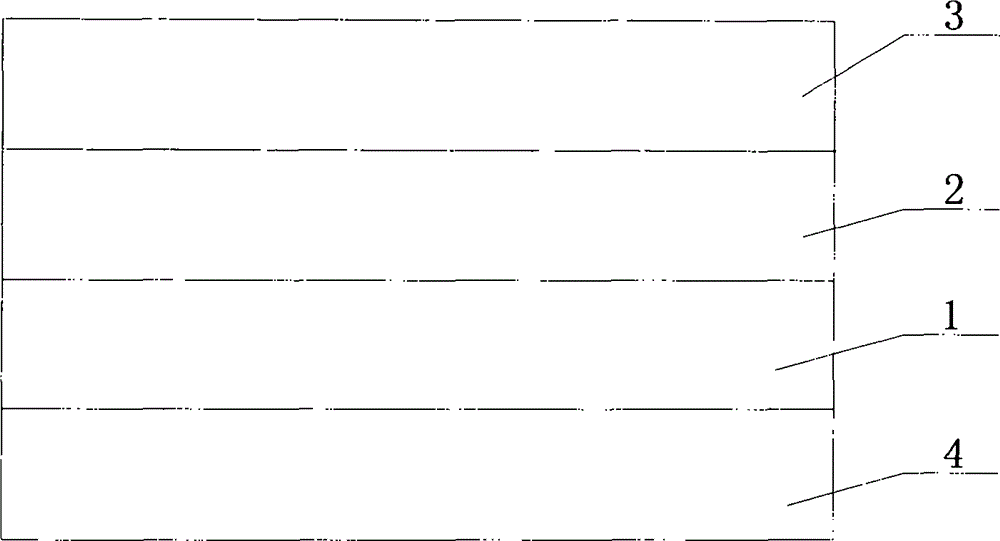

[0015] This specific embodiment adopts the following technical scheme: it comprises base paper 1, precoat 2, heat-sensitive coating 3 and back coat 4; Sensitive coating 3, the bottom of base paper 1 is provided with back coating 4.

[0016] The manufacturing process of this specific embodiment is as follows: the upper part of the base paper is coated with a pre-coat layer, the upper part of the pre-coat layer is coated with a heat-sensitive top coat layer, and the lower part of the base paper is coated with a back coat layer.

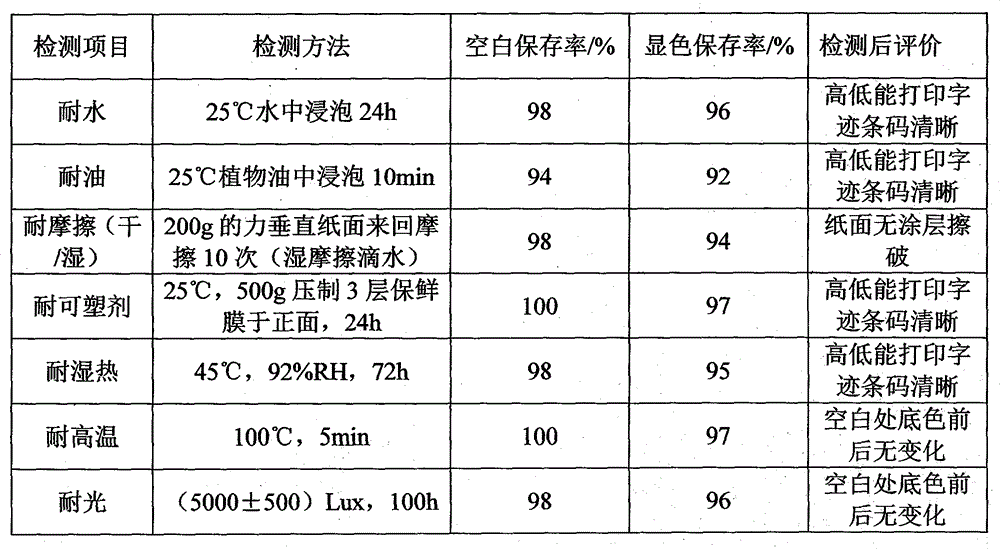

[0017] The color developer in the heat-sensitive top coat is a derivative of urea or thiourea, or a mixture with phenylsulfones and polyphenols, and the product reacted with a leuco dye has strong weather resistance, including water resistance , Oil resistance, plasticizer resistance, light resistance, high temperature resistance, dry / wet friction resistance, etc.

[0018] The base paper weight is 40~160g / m 2 , frontal smoothness 50-100s, Cobb 30s 0-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com