Coke oven raw gas waste heat recovery power generation system and method

A waste heat recovery and power generation system technology, applied in the direction of machines/engines, steam engines, mechanical equipment, etc., can solve the problems of increasing waste heat recovery costs, heat energy emissions, unutilized and other problems, and achieve a low and stable adjustment rate. The effect of continuous production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

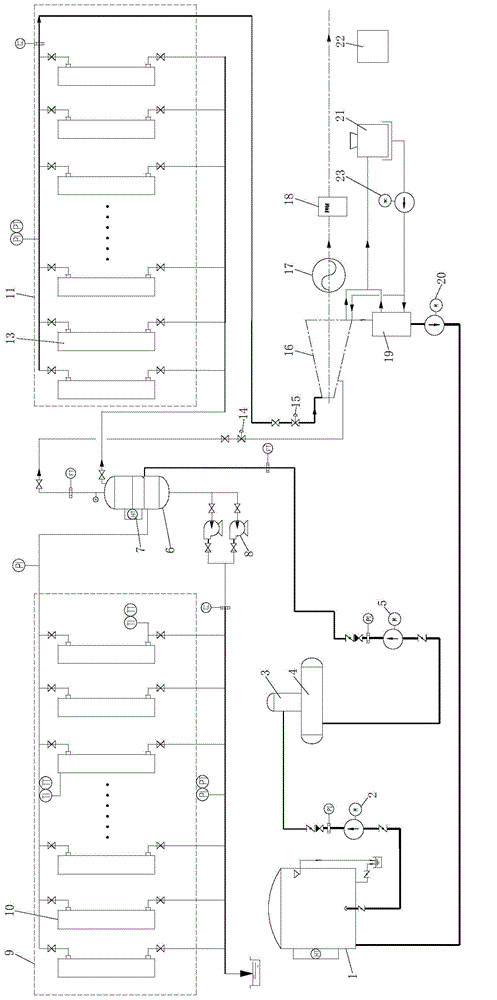

[0032] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

[0033] refer to figure 1 , the coke oven raw gas waste heat recovery power generation system of the present invention includes a steam drum 6, a forced circulation device 8, a saturated steam heat exchanger group 9, a superheated steam heat exchanger group 13, a main steam regulating valve 15, and an air supplement regulating valve 14 , steam turbine 16, generator 17.

[0034]The water outlet of the steam drum is connected with the input end of the forced circulation device, the output end of the forced circulation device is connected with the input end of the saturated steam heat exchanger group 9, and the output end of the saturated steam heat exchanger group 9 is connected with the steam drum 6 Soda mix input port connection. The saturated steam heat exchanger group 9 is composed of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com