Apparatus and method for flash vaporization continuous crystallization of calcium gluconate, and applications of method and apparatus

A calcium gluconate and vacuum technology, which is applied to the general layout of the crystallization device, evaporation separation crystallization, solution crystallization, etc., can solve the problems of uneven crystal particle size, low degree of automation, and affecting product quality, and achieve a concise crystallization process. Improvement of labor efficiency and labor productivity, effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

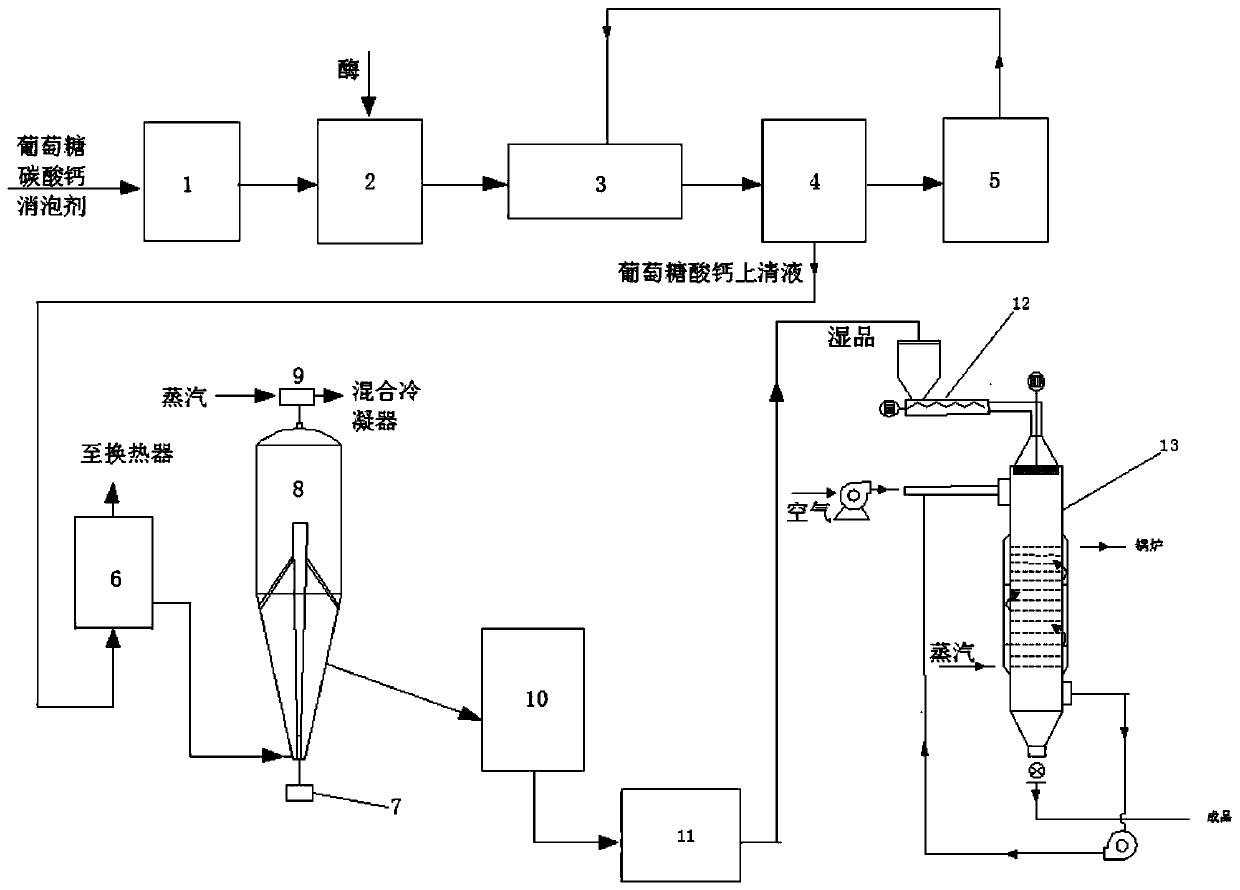

[0049] refer to figure 1 , a device for vacuum flash continuous crystallization of calcium gluconate, comprising: a first dissolution tank 1, an oxidation reaction tank 2, a plate and frame filter press 3, a primary nanofiltration membrane concentration device 4, a second dissolution tank 5, a heating Chamber 6, single-effect vacuum cooling flash crystallization device, slurry tank 10, centrifuge 11, granulator 12, internal heating fluidized bed drying device 13; wherein, the outlet of the first dissolution tank 1 is connected through a thick slurry pump The inlet of the oxidation reaction tank 2, the outlet of the oxidation reaction tank 2 is connected to the inlet of the plate and frame filter press 3, and the outlet of the plate and frame filter press 3 is connected to the primary nanofiltration membrane concentration device 4 through a security filter , the primary nanofiltration membrane concentration device 4 is connected to the second dissolution tank 5, and the second ...

Embodiment 2

[0054] A vacuum flash continuous crystallization device for calcium gluconate, the same as in Example 1, the difference is that the ratio of the straight cylinder section to the cone section of the vacuum flash cooling crystallizer 8 is 3:2. The nanofiltration membrane in the first-stage nanofiltration membrane concentration device 4 is a flat nanofiltration membrane. The slurry outlet has a length of 70 μm and a diameter of 100 μm.

Embodiment 3

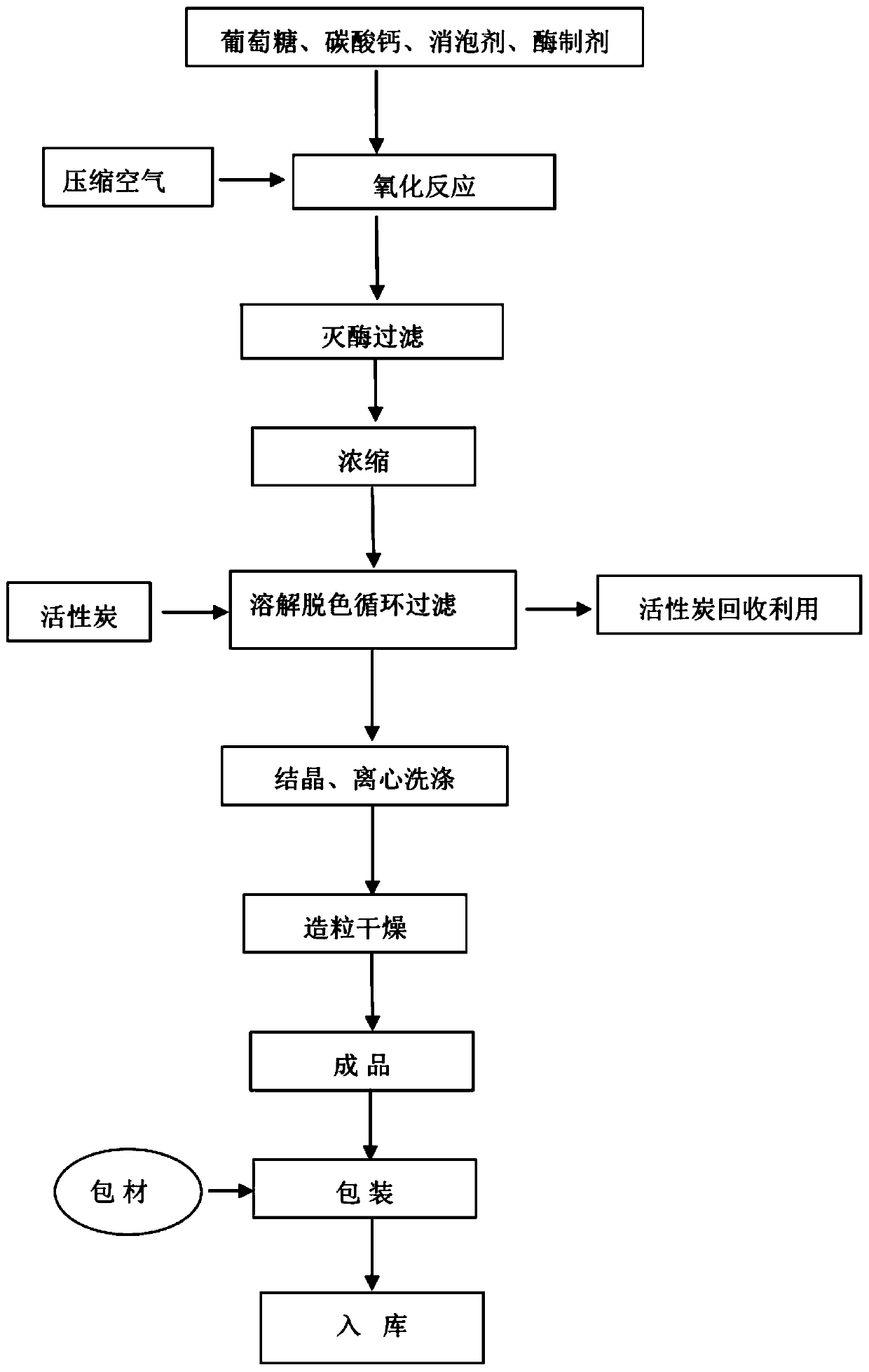

[0056] refer to figure 2 A method for calcium gluconate vacuum flash continuous crystallization adopts the device described in embodiment 1 to implement, comprising the steps:

[0057] Calcium gluconate formula is as shown in table 1:

[0058] Table 1

[0059] raw material Dosage ratio% Amount added kg purity level glucose 100 6000 pharmaceutical grade or food grade calcium carbonate 30 1800 industrial grade or food grade glucose oxidase 0.25 15 industrial grade or food grade Catalase 0.2 12 industrial grade or food grade

[0060] Note: raw material consumption ratio % in table 1 refers to the consumption weight % of other raw materials needed based on raw material glucose conversion 100% dry basis (hereinafter the same).

[0061] S1. Dissolving to constant volume: first add about 30m of purified water into the dissolving tank 3 , turn on the stirrer, add 6000kg glucose, 1800kg calcium carbonate, 2kg defoamer, 15kg gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com