Air bearing compressor for fuel cell

An air bearing and fuel cell technology, applied in the field of compressors, can solve the problems of not being able to give full play to the advantages of air bearings, low actual efficiency, and bulky volume, and achieve the effects of reducing connecting parts, reducing part quality, and improving transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be described in further detail below in conjunction with specific examples.

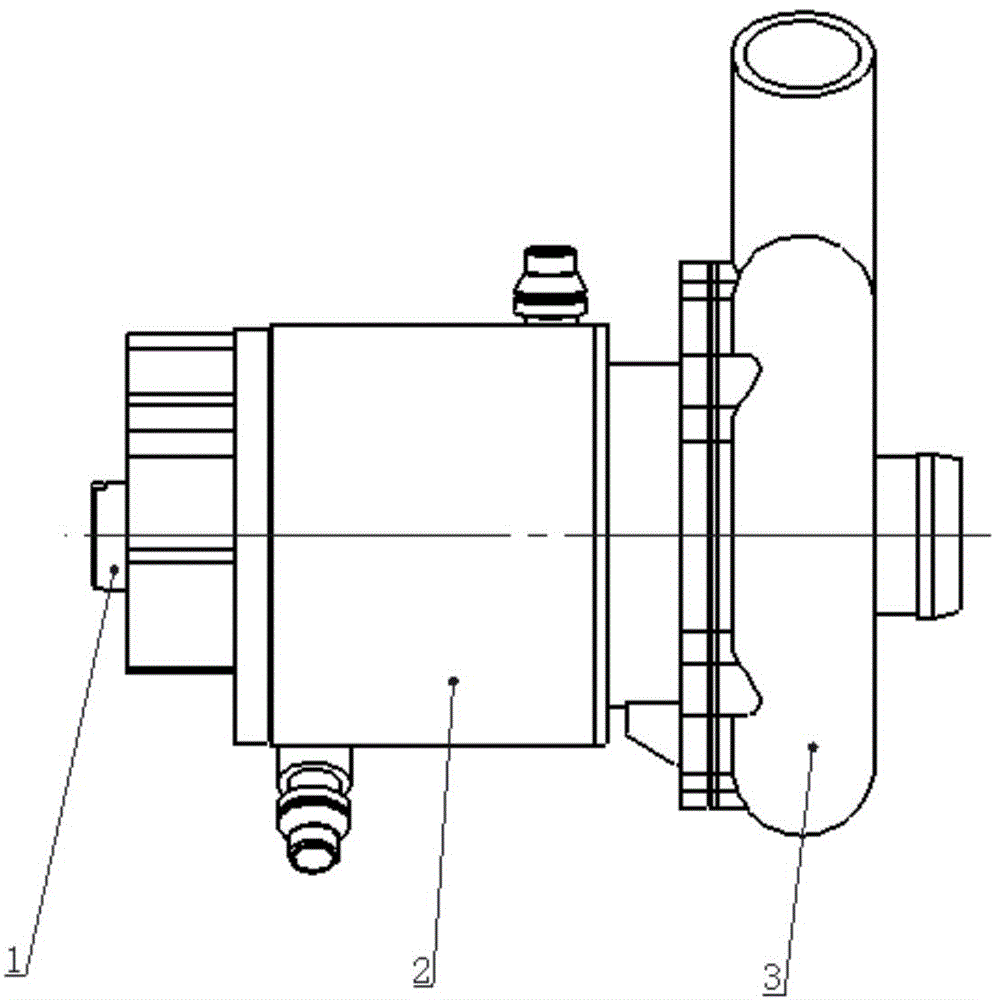

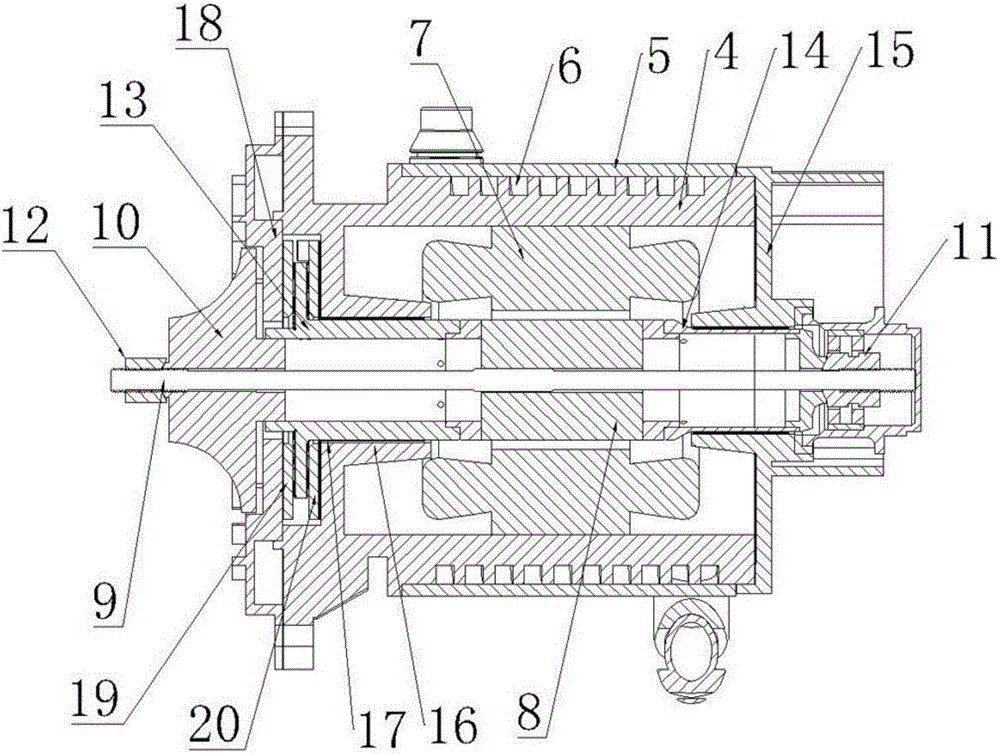

[0024] The present invention mainly divides into three parts, as figure 1 As shown, the left end is the resolver motor part 1, the middle part is the drive motor part 2, and the right end is the impeller volute part 3.

[0025] The specific implementation is as follows:

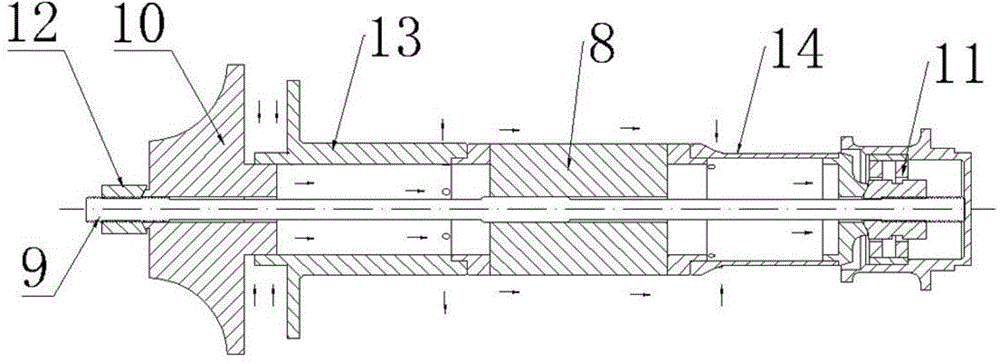

[0026] Such as figure 2 and image 3 As shown, the housing of the driving motor is composed of two parts, the inner housing 4 and the outer housing 5, both of which are in interference fit. The inner housing 4 of the motor is provided with a spiral groove cooling water channel 6, and the outer housing of the motor is provided with a water inlet. , Water outlet system, the water inlet and outlet system of the motor shell has multiple high-precision temperature sensor installation structures for multi-point temperature measurement, and the sensor feedback signal line is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com