Circulating dryer for cereals

A technology of cyclic drying and material circulation, applied in dryers, drying solid materials, drying gas layout, etc., can solve the problems of heat energy waste, inability to make full use of residual heat energy, and inability to dry grains with hot air, avoiding large air resistance, High thermal efficiency and improved uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

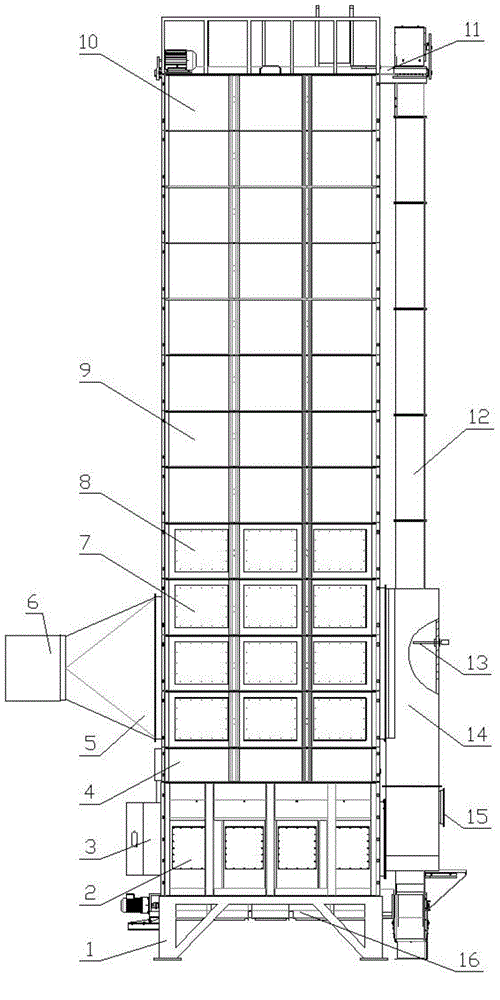

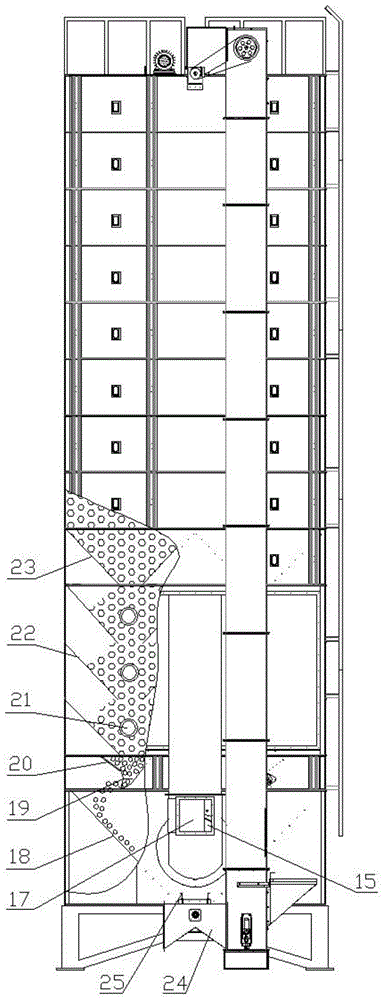

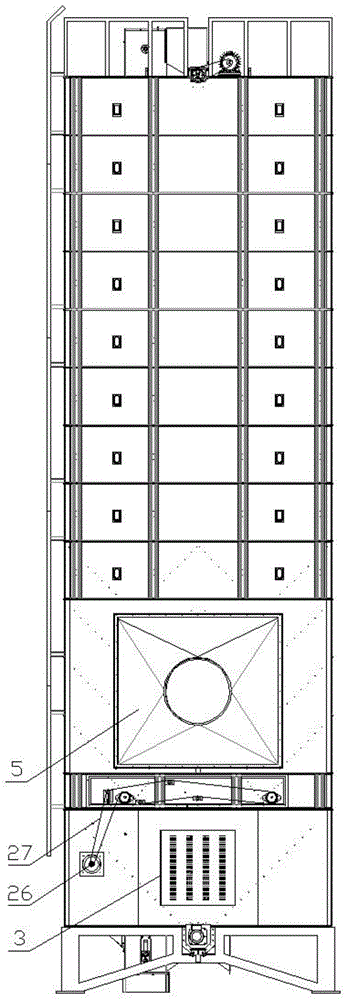

[0029] Such as figure 1 As shown, the grain circulation dryer includes a base 1 on which a radiation drying section 2, a grain discharge section 4, a hot air drying section 7 and a grain storage section are sequentially arranged from bottom to top. A material circulation conveying device is provided between the discharge port of the radiation drying section 2 and the feed port of the grain storage section. The grain storage section is formed by sequentially connecting the top grain storage section 10, the general grain storage section 9 and the bottom grain storage section 8 from top to bottom, and the general grain storage section 9 is formed by overlapping and connecting multiple sections. , the general grain storage section 9 in the present embodiment is formed by superposition of seven sections.

[0030] see figure 1 and figure 2 , the hot air drying section 7 is formed by overlapping and connecting multiple sections, and this embodiment takes three sections as an exam...

Embodiment 2

[0039] Such as Figure 1-Figure 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that there is no infrared coating layer 29 on the outer surface of the tube of the radiator 28 in the radiation drying section 2, and all the other structures are the same as in Embodiment 1, and the dryer is only hot air to the grain. Convection dry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com