Hollow silica submicro-sphere with ferroferric oxide particle and silica core, and preparation method thereof

A technology of ferric oxide and silicon dioxide, which is applied in the direction of iron oxide/ferric hydroxide, medical preparations of non-active ingredients, oxides of sub-ferric iron, etc., can solve the problem of uncontrollable growth space of ferric oxide particles The interior of the cavity and other problems, to achieve high biological stability and biocompatibility, improve the effect of contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The hollow silica submicron sphere with movable spherical silica core can be prepared with reference to CN200610089184.9.

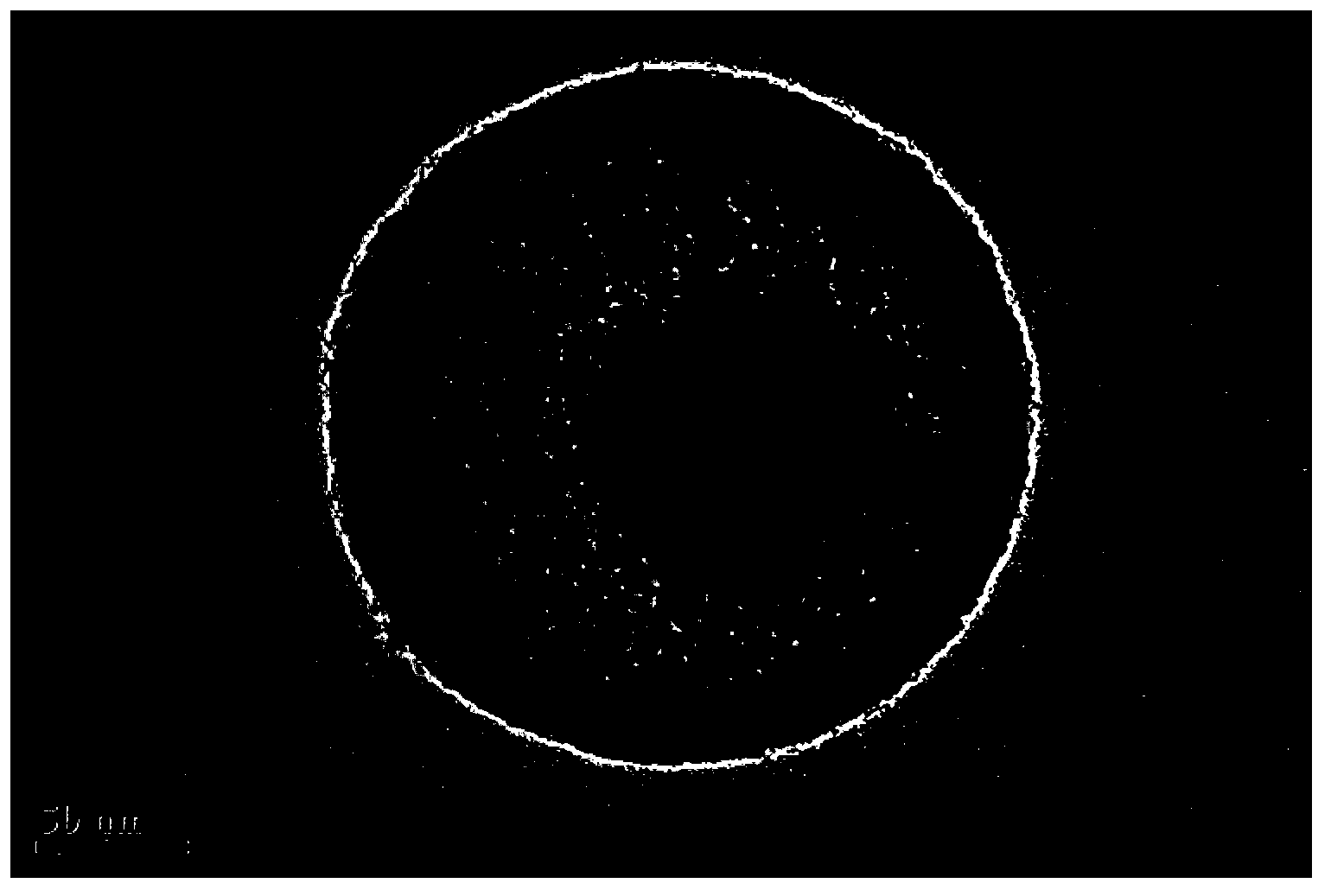

[0031] (1) The specific surface area of the movable spherical silica core with a diameter of 55nm prepared by referring to CN200610089184.9 is 280m 2 / g, a diameter of 310nm, a shell thickness of 21nm, and a hollow silica submicron sphere with an average pore diameter of 3 to 5nm in the mesopores of the shell, soaked in a 1M ferrous ammonium sulfate aqueous solution for 24 hours, Wherein, the mass of the hollow silica submicron sphere with the movable spherical silica inner core accounts for 0.1% of the total mass of the hollow silica submicron sphere with the movable spherical silica inner core and the ferrous ammonium sulfate aqueous solution ; Centrifugation obtains the hollow silica submicron ball with movable spherical silica inner core loaded with ferrous ammonium sulfate;

[0032] (2) Disperse the hollow silica submicron spheres loaded wi...

Embodiment 2

[0035] The hollow silica submicron sphere with movable spherical silica core can be prepared with reference to CN200610089184.9.

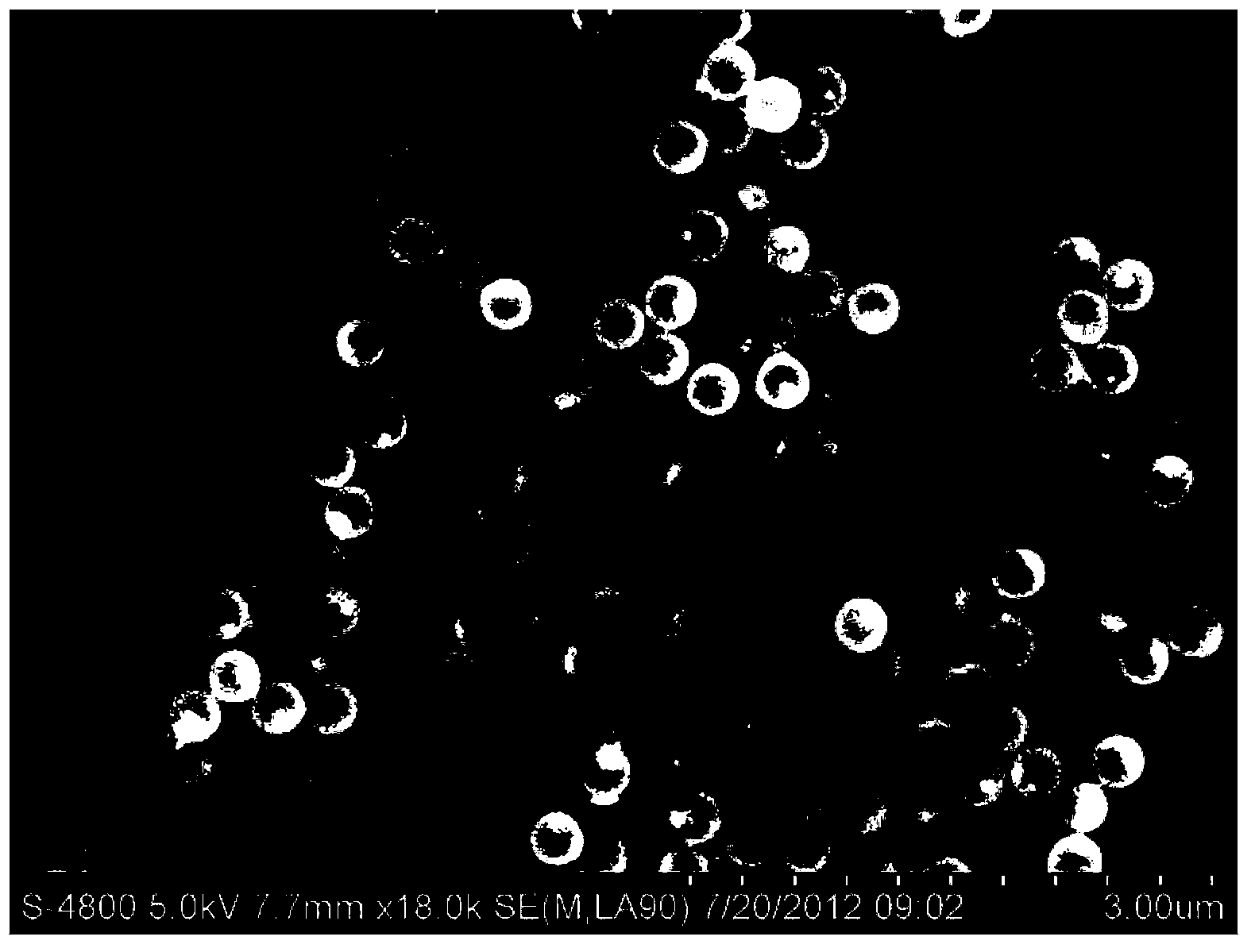

[0036] (1) The specific surface area of the movable spherical silica core with a diameter of 540nm prepared by referring to CN200610089184.9 is 460m 2 / g, a diameter of 980nm, a shell thickness of 100nm, and a hollow silicon dioxide submicron sphere with an average pore diameter of 10nm in the mesopores of the shell was immersed in a 2M ammonium ferrous sulfate aqueous solution for 24 hours, wherein, The mass of the hollow silica submicron sphere with the movable spherical silica inner core accounts for 1% of the total mass of the hollow silica submicron sphere with the movable spherical silica inner core and the ferrous ammonium sulfate aqueous solution; centrifugation The hollow silica submicron spheres with movable spherical silica inner core loaded with ammonium ferrous sulfate are separated;

[0037] (2) Disperse the hollow silica submicron...

Embodiment 3

[0040] The hollow silica submicron sphere with movable spherical silica core can be prepared with reference to CN200610089184.9.

[0041] (1) The specific surface area of the movable spherical silica core with a diameter of 50nm prepared by referring to CN200610089184.9 is 140m 2 / g, a diameter of 500nm, a shell thickness of 25nm, and a hollow silica submicron sphere with an average pore diameter of 3 to 5nm in the mesopores of the shell, soaked in an aqueous solution of 1M ferrous ammonium sulfate for 12 hours, Wherein, the mass of the hollow silica submicron sphere with the movable spherical silica inner core accounts for 20% of the total mass of the hollow silica submicron sphere with the movable spherical silica inner core and the ferrous ammonium sulfate aqueous solution ; Centrifugation obtains the hollow silica submicron ball with movable spherical silica inner core loaded with ferrous ammonium sulfate;

[0042] (2) Disperse the hollow silica submicron spheres loaded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com