An integrated lightweight oxygen generating system and its compressor

An oxygen production system, lightweight technology, used in liquid fuel engines, rotary piston machines, pump combinations for elastic fluid rotary piston/oscillating pistons, etc. High requirements for problems, to achieve the effect of reducing adsorbent loading, reducing volume and weight, and high energy utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

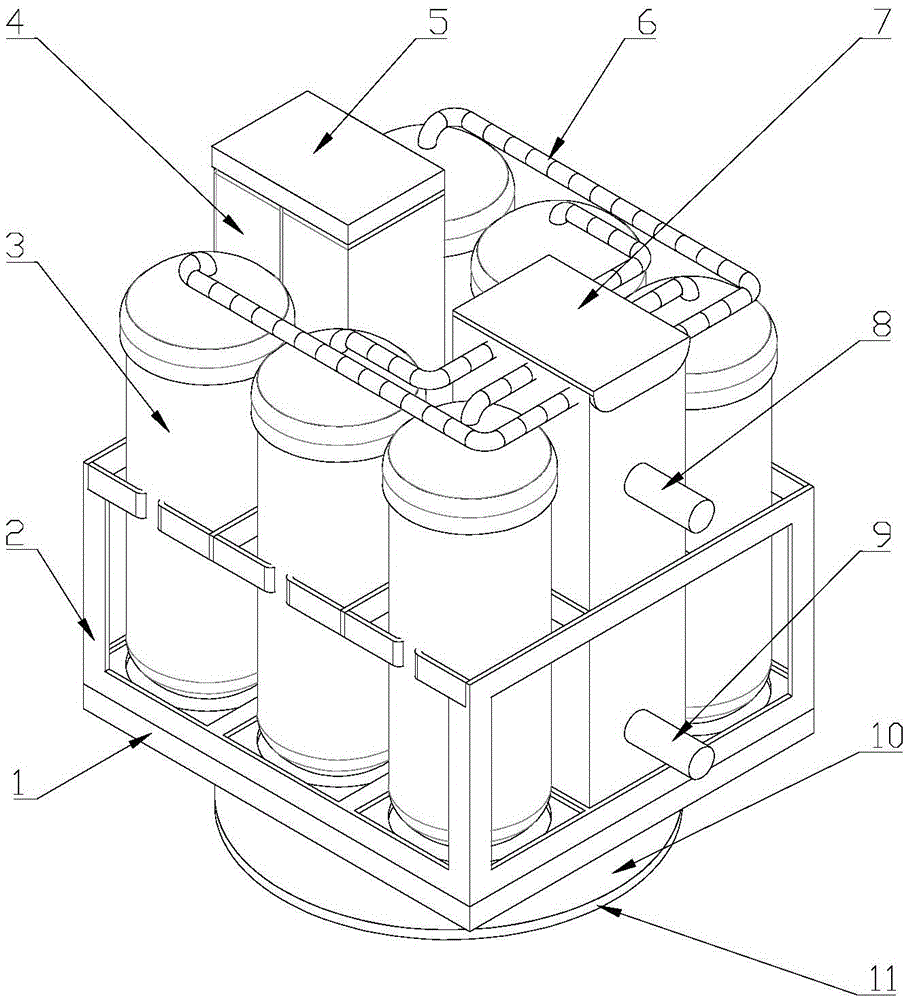

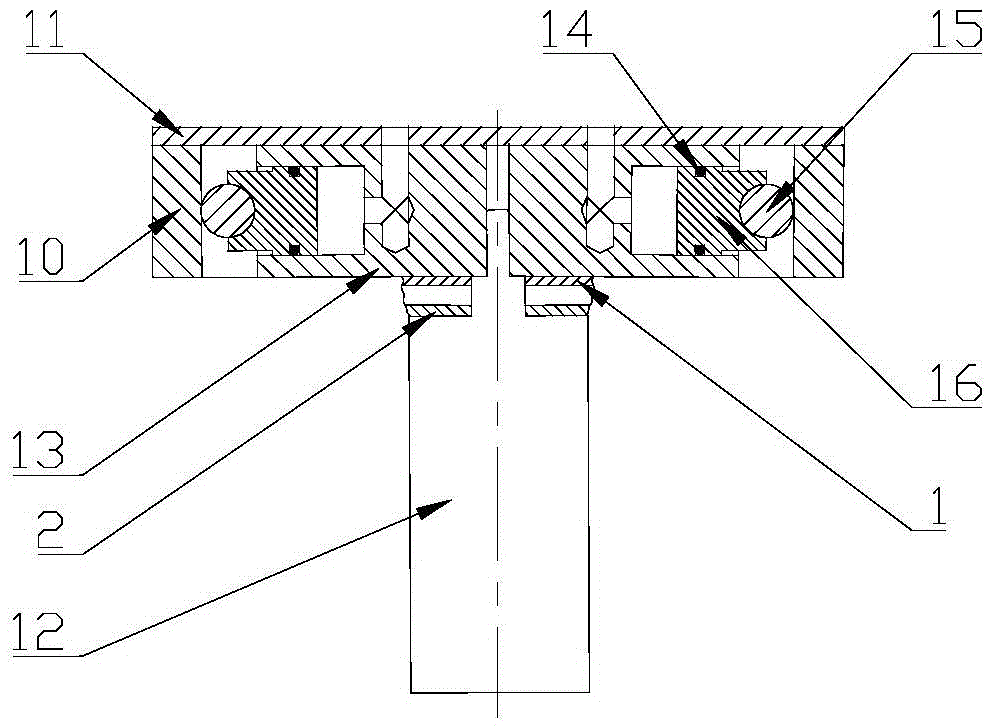

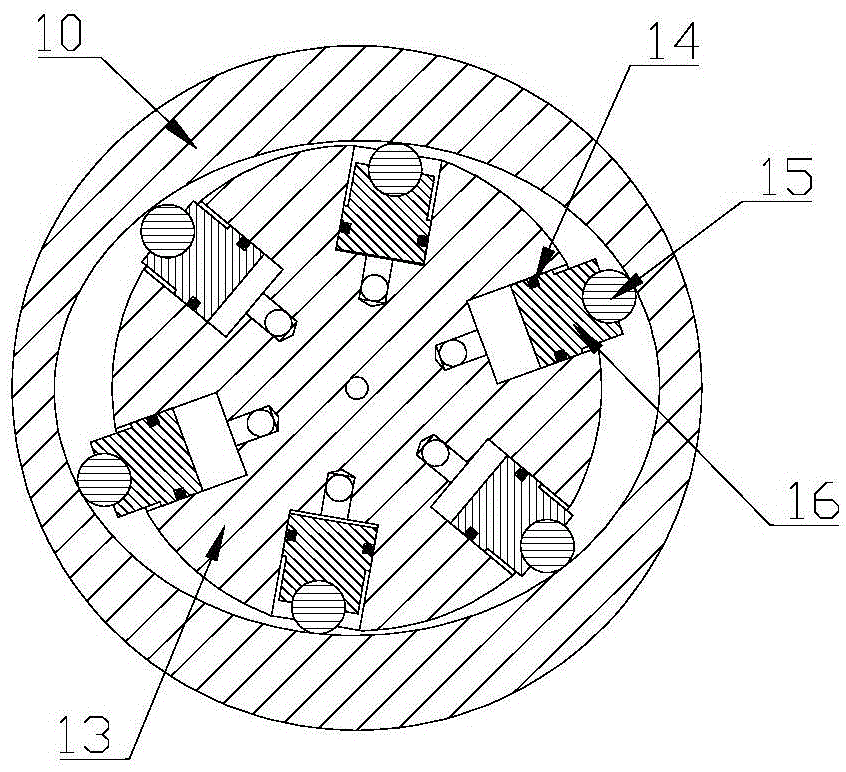

[0022] refer to figure 1 , an integrated lightweight oxygen generation system and its compressor, including an air compressor, an oxygen generation system, and a grid support system. The air compressor and the oxygen generation system are installed and fixed on the grid support system; the air compression includes DC The motor and the air compressor host, the DC motor 12 is placed at the center of the grid frame 2, and the output end of the DC motor 12 passes through the grid frame to connect with the rotor 13 of the air compressor host; the exhaust port of the air compressor host passes through the pipeline and the oxygen generator The multifunctional valve in the system is connected with the gas storage container integration box 7, and the two ends of the adsorption tower in the oxygen generation system are respectively connected with the multifunctional valve and the gas storage container integration box 7 through pipelines; more than two adsorption towers 3 and the multifun...

Embodiment 2

[0029] refer to figure 1 with Figure 5 , the number of adsorption towers in this embodiment is 6, that is, n=6; when oxygen production is working, multi-tower boosting adsorption oxygen production, n 解吸 One tower depressurization desorption, adopts 2 tower depressurization adsorptions in the present embodiment, promptly the adsorption tower number n of booster adsorption 吸附 =n-n 解吸 = 4, the number of adsorption towers for boosting adsorption is greater than the number of adsorption towers for step-down desorption, namely n 吸附 >n 解吸 ; The weight of the adsorbent required for a certain product gas requirement is M, and the weight of the adsorbent required in each adsorption tower is or In the present embodiment, the adsorbent weight required in the adsorption tower is After working for a period of time t, the two adsorption towers originally used for step-down desorption start to increase the pressure and absorb oxygen, that is, the adsorption towers 3A and 3B start to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com