Preparation method of graphene

A technology of graphene and graphene dispersion liquid, which is applied in the field of graphene preparation, can solve the problems of low graphene yield and achieve the effects of excellent product performance, improved preparation efficiency, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

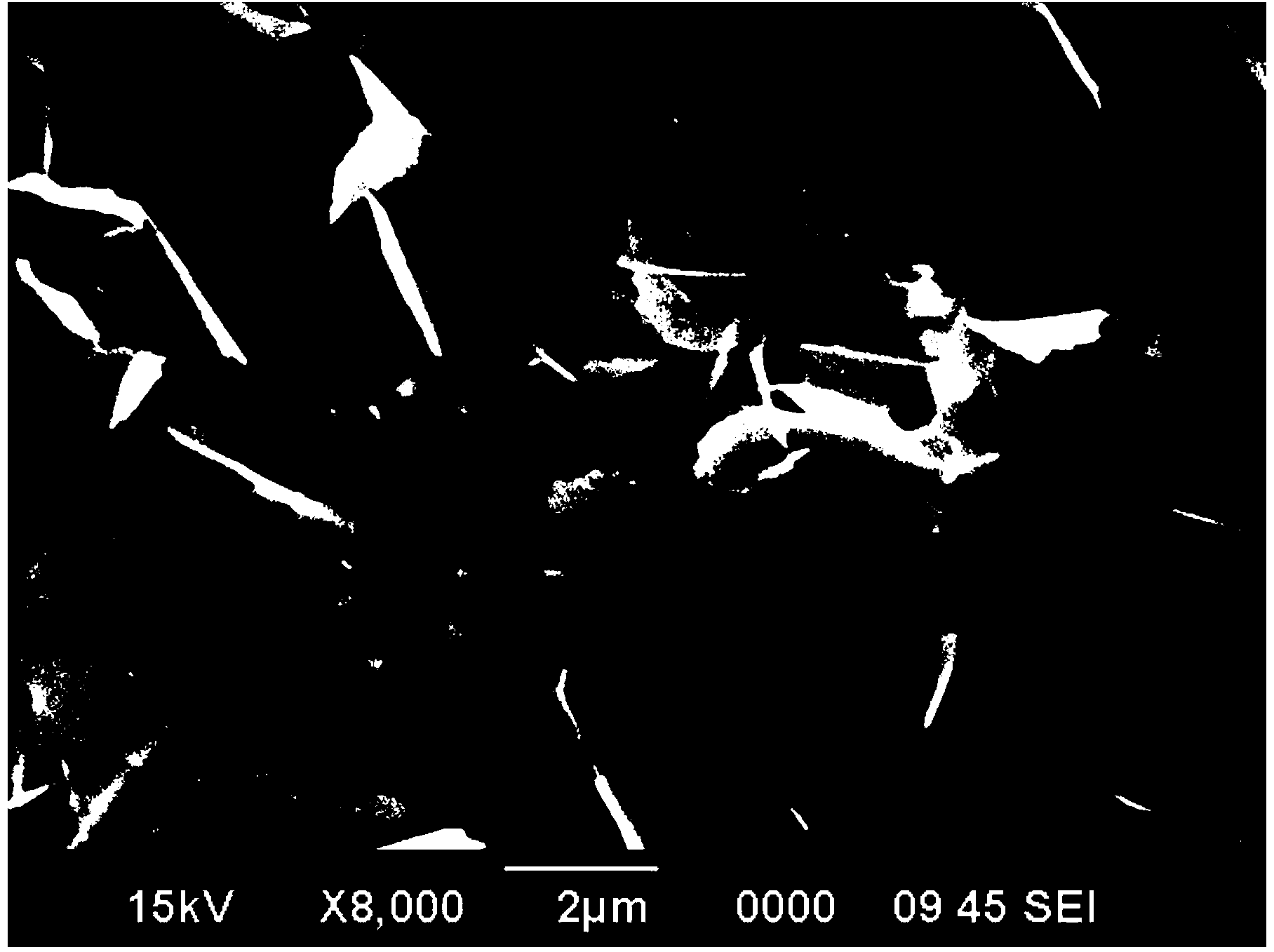

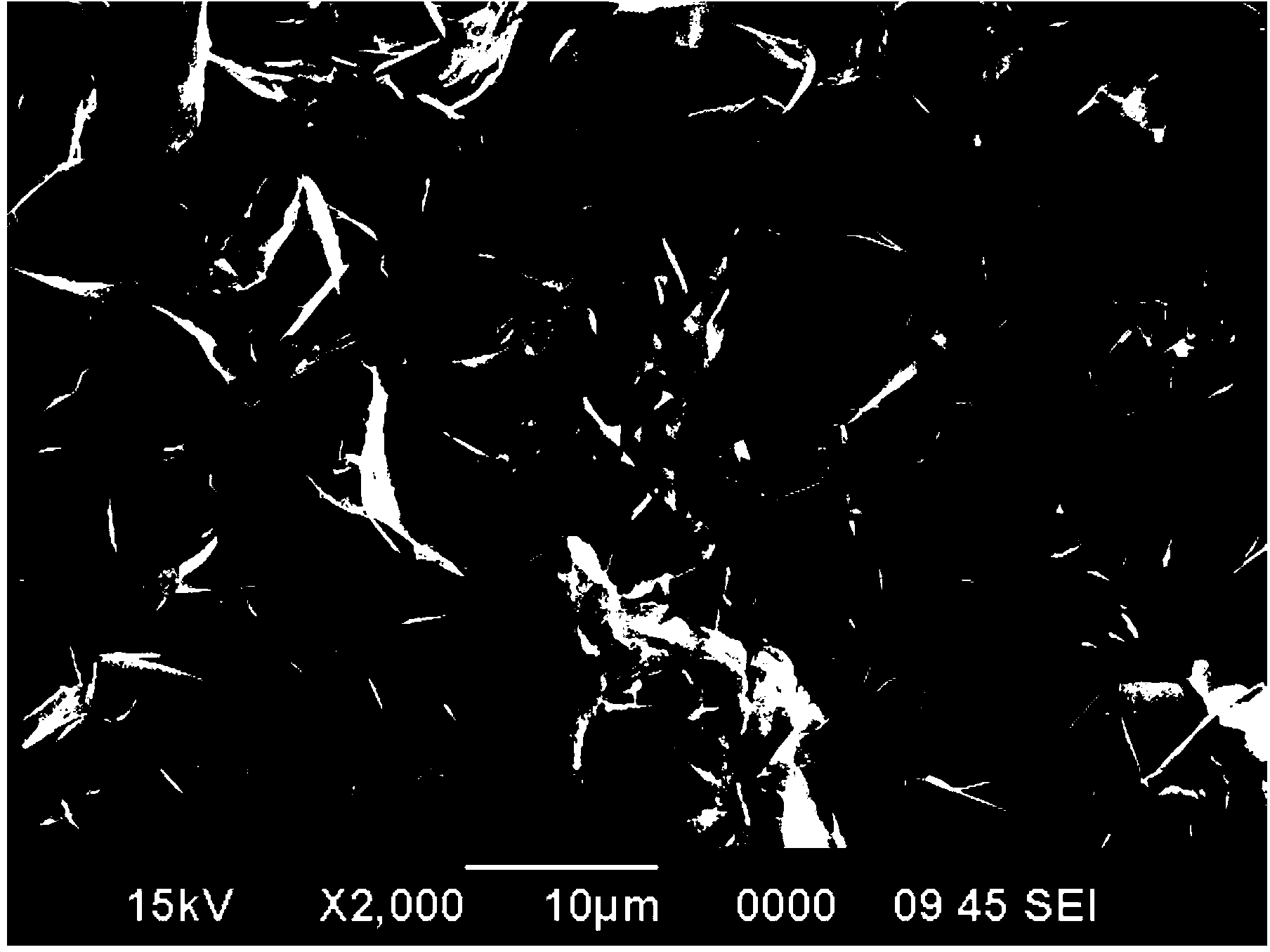

Image

Examples

Embodiment 1

[0053] 1. Add 1g of 500-mesh granular natural graphite and 0.5g of sodium nitrate into a 250mL three-necked flask under ice-water bath conditions. Then slowly add 24mL concentrated sulfuric acid (mass concentration: 98%) into the there-necked flask and stir thoroughly to keep the reaction temperature of the system at about 0°C. First, use an ultrasonic cell pulverizer with a working frequency of 20kHz and an ultrasonic power of 800w for 15 minutes, and then use Ultrasonic treatment with an ultrasonic cleaner with a working frequency of 20kHz and an ultrasonic power of 120w for 30 minutes, and finally ultrasonic treatment with an ultrasonic cell pulverizer with a working frequency of 20kHz and an ultrasonic power of 800w for 15 minutes. During the ultrasonic treatment, an ice bath must be used to keep the system temperature at about 0 ℃, fully stirred for 2~3h after ultrasonic treatment.

[0054] 2. Add 3.0 g of potassium permanganate into a three-necked flask, keep the tempera...

Embodiment 2

[0064] 1. Add 1g of 500-mesh granular natural graphite and 0.5g of sodium nitrate into a 250mL three-necked flask under ice-water bath conditions. Then slowly add 24mL concentrated sulfuric acid (mass concentration: 98%) into the there-necked flask and stir well to keep the reaction temperature of the system at about 0°C. First, use an ultrasonic cleaner with a working frequency of 20kHz and an ultrasonic power of 120w for 15 minutes, and then use a working Ultrasonic treatment with a frequency of 20kHz and an ultrasonic power of 800w for 30 minutes, and finally ultrasonic treatment with an ultrasonic cleaner with a working frequency of 20kHz and an ultrasonic power of 120w for 15 minutes. During the ultrasonic treatment, an ice bath must be used to keep the system temperature at about 0°C , fully stirred for 2~3h after ultrasonic treatment.

[0065] 2. Add 3.0 g of potassium permanganate into a three-necked flask, keep the temperature of the reaction system below 10°C, keep t...

Embodiment 3

[0074] 1. Add 1g of 500-mesh granular natural graphite and 0.5g of sodium nitrate into a 250mL three-necked flask under ice-water bath conditions. Then slowly add 24mL of concentrated sulfuric acid (mass concentration: 98%) into the three-necked flask and stir thoroughly, keeping the reaction temperature of the system not higher than 5°C, and fully react for 3 hours.

[0075] 2. Add 3.0g of potassium permanganate into the three-necked flask, keep the temperature of the reaction system at 20-30°C, and keep stirring for 3 hours.

[0076] 3. Add 500ml of crushed ice cubes, and add 20ml of hydrogen peroxide solution with a mass concentration of 3% drop by drop until the gas completely escapes.

[0077] 4. Add 20ml of hydrochloric acid with a mass concentration of 10%, react fully, and repeat centrifugation with deionized water not higher than 10°C until the pH of the supernatant is neutral.

[0078] 5. The obtained precipitate is ultrasonically treated with an ultrasonic pulveriz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com