Novel three kettle polymerization process of chinlon 6

A kettle polymerization and process technology, which is applied in the field of continuous polymerization production of chemical fiber spinning raw material nylon 6 slices, can solve the problems of large polymerization kettle equipment, complex equipment structure, and no consideration of repolymerization, etc., and achieves a wide range of strength and tensile properties. The effect of simple equipment structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

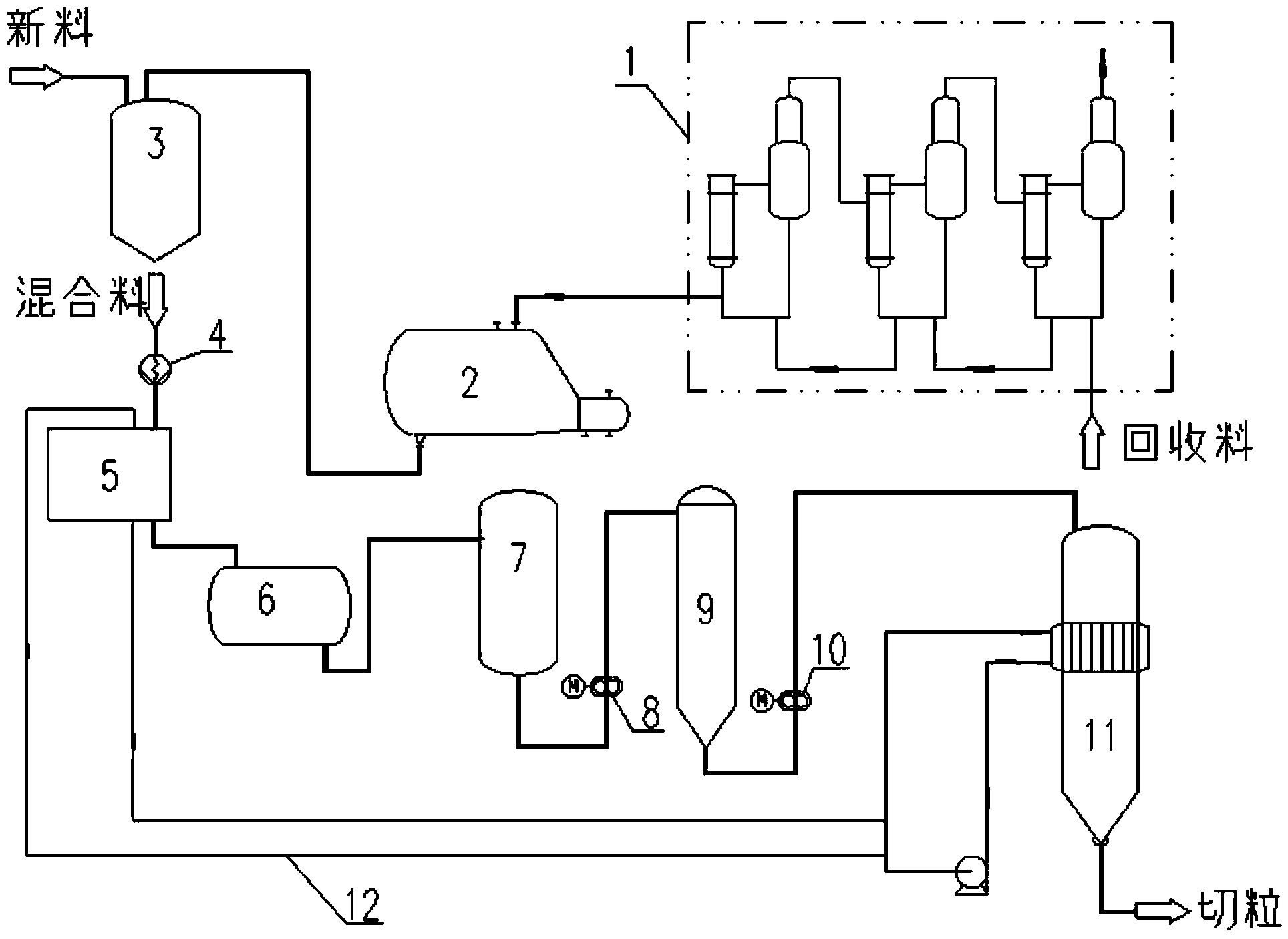

[0032] Specific examples of the present invention are attached figure 1 As shown, using the three-pot polymerization technology of the present invention, the output of nylon 6 slices is 100 tons per day, and about 30 tons of reclaimed materials are used. The process is as follows:

[0033] 1. Preparation of fresh raw materials:

[0034] The fresh caprolactam raw material prepared according to the conventional method should be a liquid material. Whether it is melted from a solid caprolactam material or directly purchased from a liquid caprolactam material, it should be kept in hot water at about 85-100°C and stored in a storage tank protected by nitrogen. In, and then sent out with a jacket insulation pump.

[0035] 2. Preparation of additives:

[0036] This example only exemplifies the case of using one additive, that is, using terephthalic acid (PTA). Dissolve PTA in liquid caprolactam according to the general method to prepare a caprolactam solution containing about 6% PT...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com