Oxidized graphene modified foam material and preparation method thereof

A graphene modification and foaming material technology, applied in the field of foaming materials, can solve problems such as lack of conductive foamed conductive material preparation methods, and achieve the effects of retaining biodegradable properties, controllable density, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

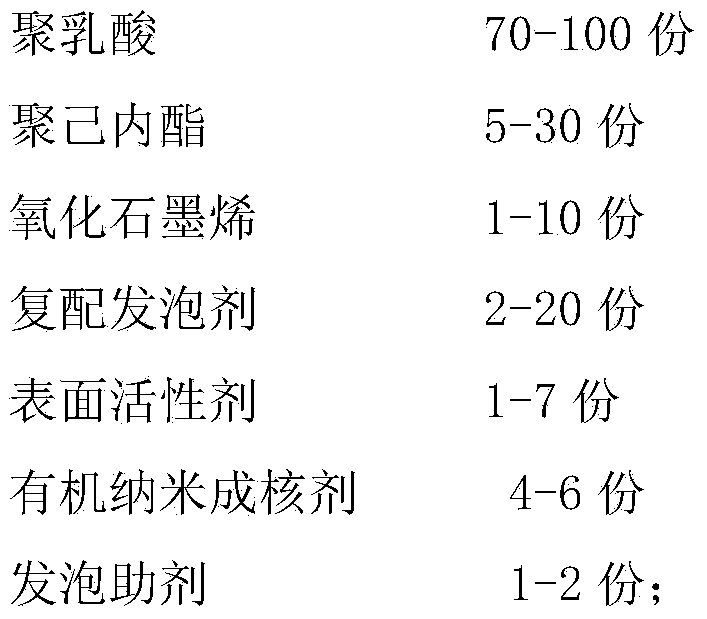

[0031] A graphene oxide modified foam material of the present invention is composed of the following components by weight: 70 parts of polylactic acid (the mass ratio of model 4032D and model 2002D is: 1:1), 1 part of graphene oxide, 30 parts of polycaprolactone, 2 parts of compound foaming agent, 1 part of surfactant, 4 parts of organic nano-nucleating agent, 1 part of foaming aid;

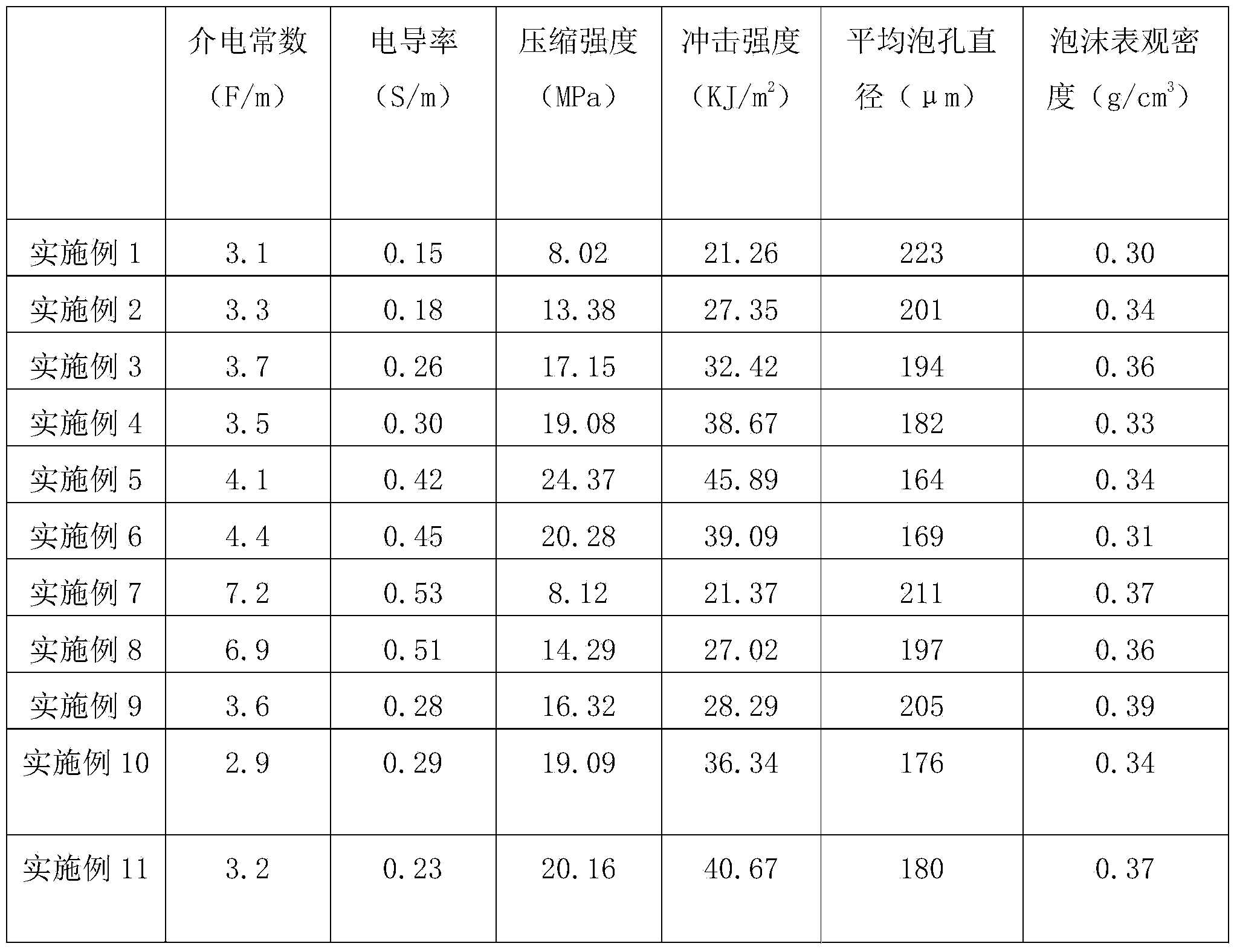

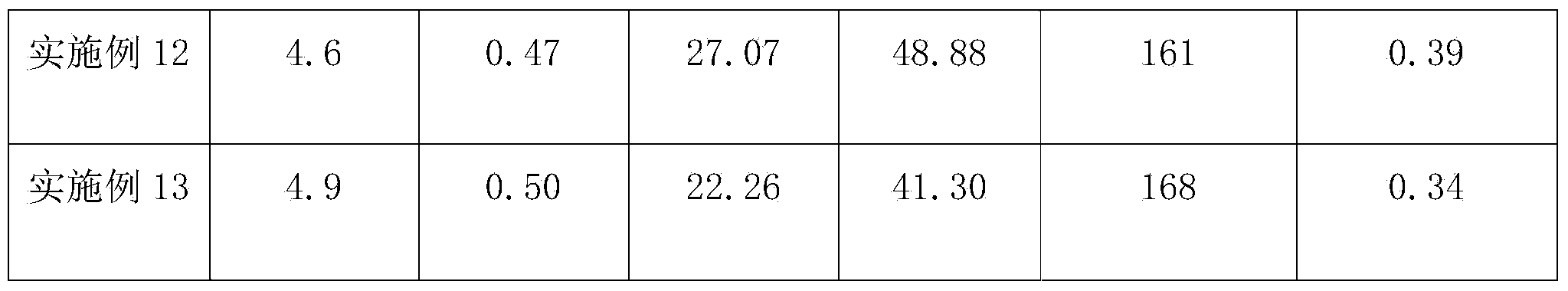

[0032] The dielectric constant of the graphene oxide modified foam material is 2F / m-9F / m, the electrical conductivity is 0.10S / m-0.80S / m, and the apparent density is 0.10g / cm 3 ~0.90g / cm 3 , compressive strength is 5~30MPa, impact strength is 10~85KJ / m 2 , The average cell diameter is 100 ~ 300um.

[0033] The polylactic acid is a matrix resin, graphene oxide is a conductive material, and flexible and biodegradable polycaprolactone is a toughening agent; the purity of the graphene oxide is not less than 99%, and the particle size of less than or equal to 30um is ≥95 The graphite powder adopts ...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is: a kind of graphene oxide modified foam material of the present invention is made up of the component that comprises following parts by weight: 75 parts of polylactic acid (the mass ratio of model 4032D and model 2002D is: 1:1), 1 part of graphene oxide, 25 parts of polycaprolactone, 5 parts of compound foaming agent, 3 parts of surfactant, 4 parts of organic nano-nucleating agent, and 1 part of foaming aid.

[0051] The preparation method of the graphene oxide modified foaming material of the present invention, in step (3), 39g of the foaming masterbatch is placed in the mould, and the flat vulcanizer is heated to 158 ℃ foam molding, foaming The time is 50 minutes. Obtain an apparent density of 0.34g / cm 3 Graphene oxide modified foam material.

Embodiment 3

[0053] The difference between embodiment 3 and embodiment 1 is: a kind of graphene oxide modified foaming material of the present invention, is made up of the component that comprises following parts by weight: 80 parts of polylactic acid (the mass ratio of model 4032D and model 2002D is: 1:1), 3 parts of graphene oxide, 20 parts of polycaprolactone, 5 parts of compound foaming agent, 3 parts of surfactant, 4 parts of organic nano-nucleating agent, and 1 part of foaming aid.

[0054] The preparation method of the graphene oxide modified foaming material of the present invention, in step (3), 39g of the foaming masterbatch is placed in the mould, and the flat vulcanizer is heated to 158 ℃ foam molding, foaming The time is 50 minutes. Obtain an apparent density of 0.36g / cm 3 Graphene oxide modified foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com