Preparation method of ZnB2O4:Eu<3+> luminescent material

A luminescent material, znb2o4 technology, applied in the field of chemistry, can solve the problems of shape, difficult to control particle size, insufficient luminous intensity of products, low product purity, etc., to achieve the effect of improving product purity, small particle size, and easy source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1): Preparation of Zn[B 3 o 3 (OH) 5 ]H 2 O:Eu 3+

[0033] 2.87g ZnSO 4 ·7H 2 O, 3.81g Na 2 B 4 o 7 10H 2 O and 0.105g Eu 2 o 3 Dissolve in 80mL distilled water, ZnSO 4 ·7H 2 O and Na 2 B 4 o 7 10H 2 O, Eu 2 o 3 The molar ratio of double-distilled water is 1:1:0.06:450, stirred at room temperature for 48 hours, the reaction product was separated by suction filtration, washed three times with double-distilled water and absolute ethanol respectively, and dried in an oven at 40°C for 24 hours , get Zn[B 3 o 3 (OH) 5 ]H 2 O:Eu 3+ .

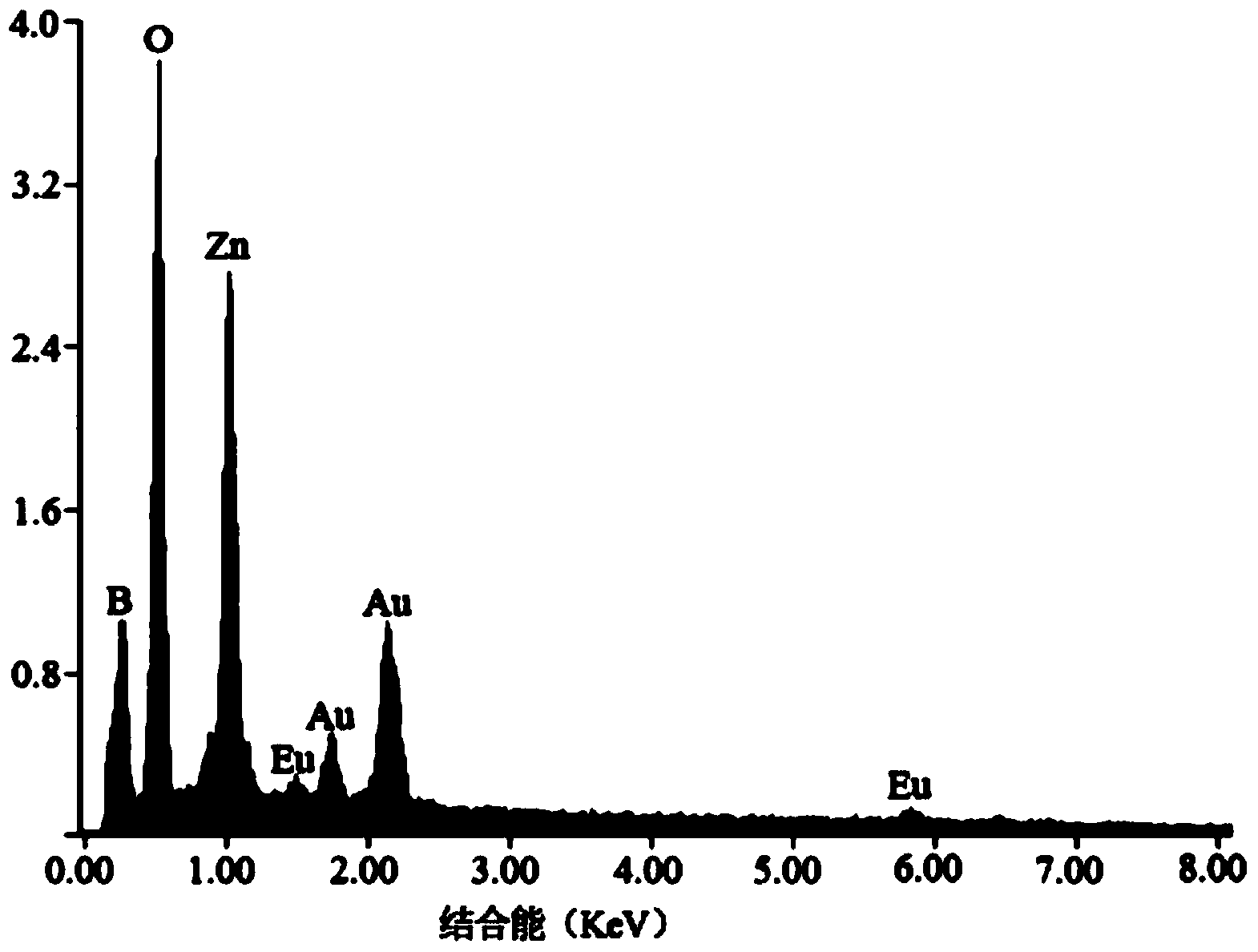

[0034] Step 2): Preparation of ZnB 2 o 4 :Eu 3+ Luminescent material

[0035] With the Zn[B that step 1) obtains 3 o 3 (OH) 5 ]H 2 O:Eu 3+ Calcined at 900°C for 6 hours and cooled to obtain ZnB 2 o 4 :Eu 3+ Luminescent material.

Embodiment 2

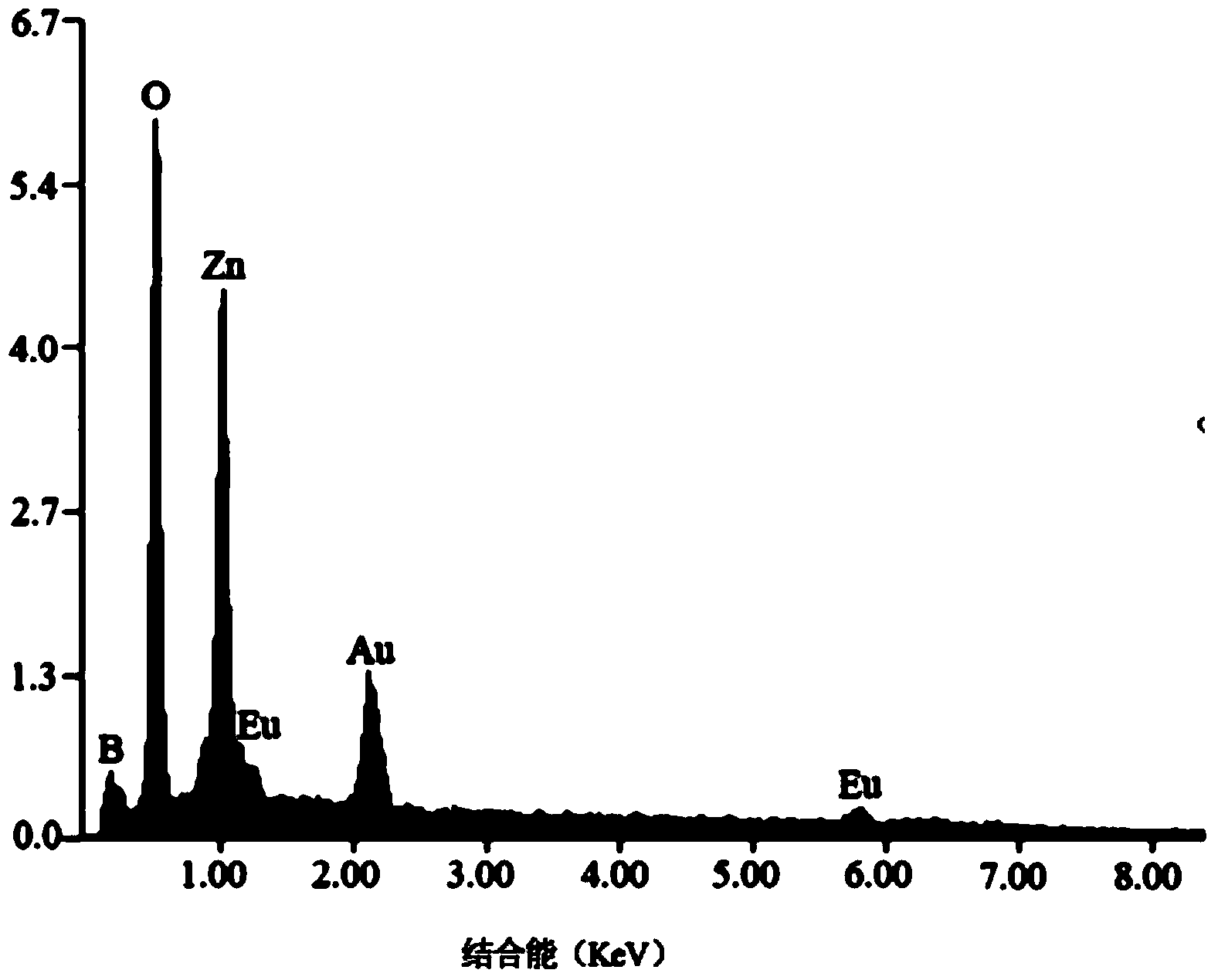

[0049] In the preparation Zn[B of embodiment 1 3 o 3 (OH) 5 ]H 2 O:Eu 3+ In step 1, 2.87g ZnSO 4 ·7H 2 O, 1.91gNa 2 B 4 o 7 10H 2 O and 0.05g Eu 2 o 3 Dissolve in 45mL distilled water, ZnSO 4 ·7H 2 O and Na 2 B 4 o 7 10H 2 O, Eu 2 o 3 , the molar ratio of double distilled water is 1: 0.5: 0.03: 250, stirred at room temperature for 36 hours, the reaction product was separated by suction filtration, washed 3 times with double distilled water and absolute ethanol respectively, and dried at 40°C for 24 hours in an oven. hour, get Zn[B 3 o 3 (OH) 5 ]H 2 O:Eu 3+ . Other steps are identical with embodiment 1, are prepared into ZnB 2 o 4 :Eu 3+ Luminescent material.

Embodiment 3

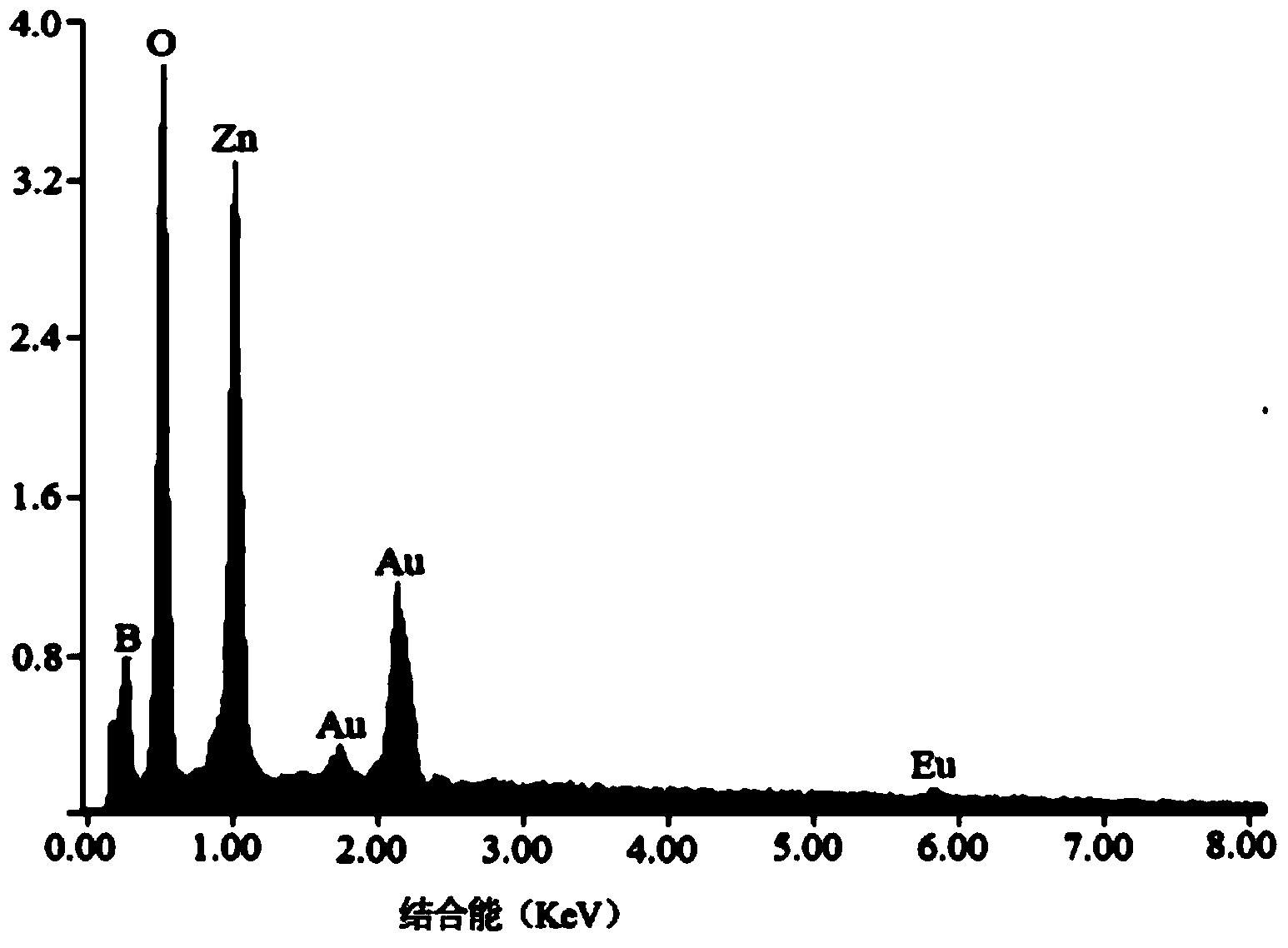

[0051] In the preparation Zn[B of embodiment 1 3 o 3 (OH) 5 ]H 2 O:Eu3+ In step 1, 2.87g ZnSO 4 ·7H 2 O, 5.72gNa 2 B 4 o 7 10H 2 O and 0.07g Eu 2 o 3 Dissolve in 63mL distilled water, ZnSO 4 ·7H 2 O and Na 2 B 4 o 7 10H 2 O, Eu 2 o 3 , the molar ratio of twice distilled water is 1: 1.5: 0.04: 350, stirred at room temperature for 14 hours, the reaction product was separated by suction filtration, washed 3 times with twice distilled water and absolute ethanol respectively, and dried at 40°C for 24 hours in an oven. hour, get Zn[B 3 o 3 (OH) 5 ]H 2 O:Eu 3+ . Other steps are identical with embodiment 1, are prepared into ZnB 2 o 4 :Eu 3+ Luminescent material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com