Film forming method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

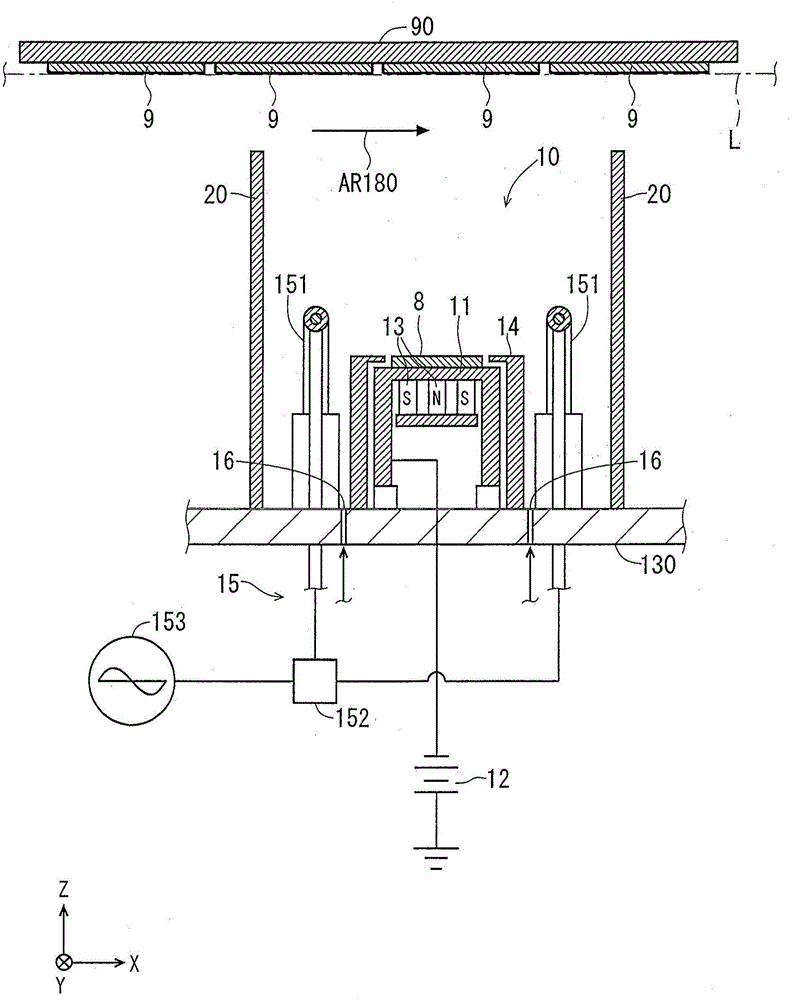

[0054] Embodiments will be described below with reference to the drawings. In addition, the following embodiment is an example which actualized this invention, and is not an example for limiting the technical scope of this invention. In addition, for easy understanding, in the drawings, the size and number of each part may be exaggerated or simplified. In addition, in some of the drawings, XYZ orthogonal coordinate axes are indicated for explaining directions. The Z-axis direction among these coordinate axes indicates the direction of the vertical line, and the XY plane is a horizontal plane.

[0055]

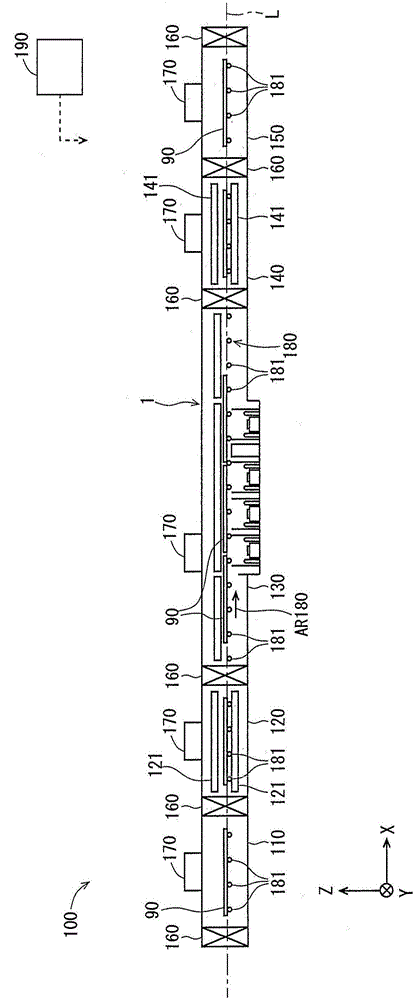

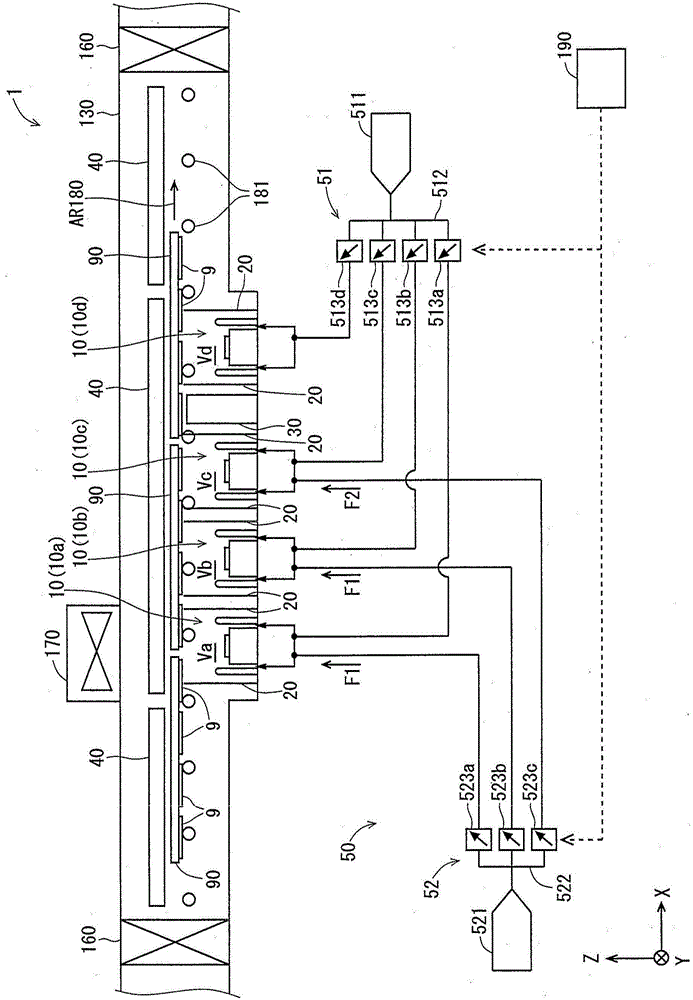

[0056] while referring to figure 1 , the overall structure of the film forming apparatus 100 will be described. figure 1 is a diagram schematically showing a schematic configuration of the film forming apparatus 100 . In addition, in figure 1 and later referenced figure 2 , Figure 7 In , the interior of the chamber is seen through the side walls of the chamber.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com