RFeB-based magnet

A manufacturing method and technology of magnets, which are applied in the manufacture of inductors/transformers/magnets, magnetic objects, and the application of magnetic films to substrates, etc., can solve the problems of reducing the coercivity of the indicated magnetic field resistance and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

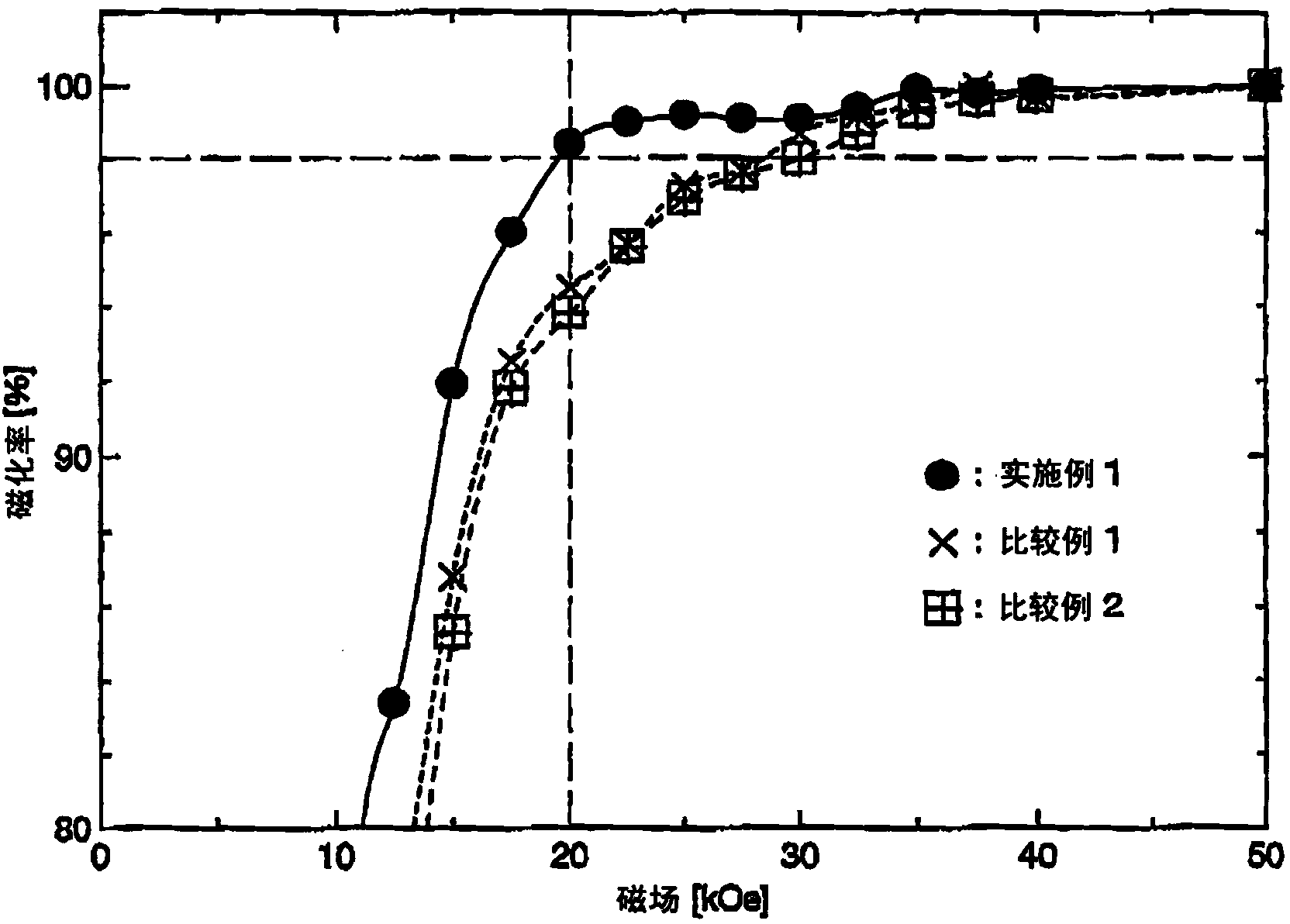

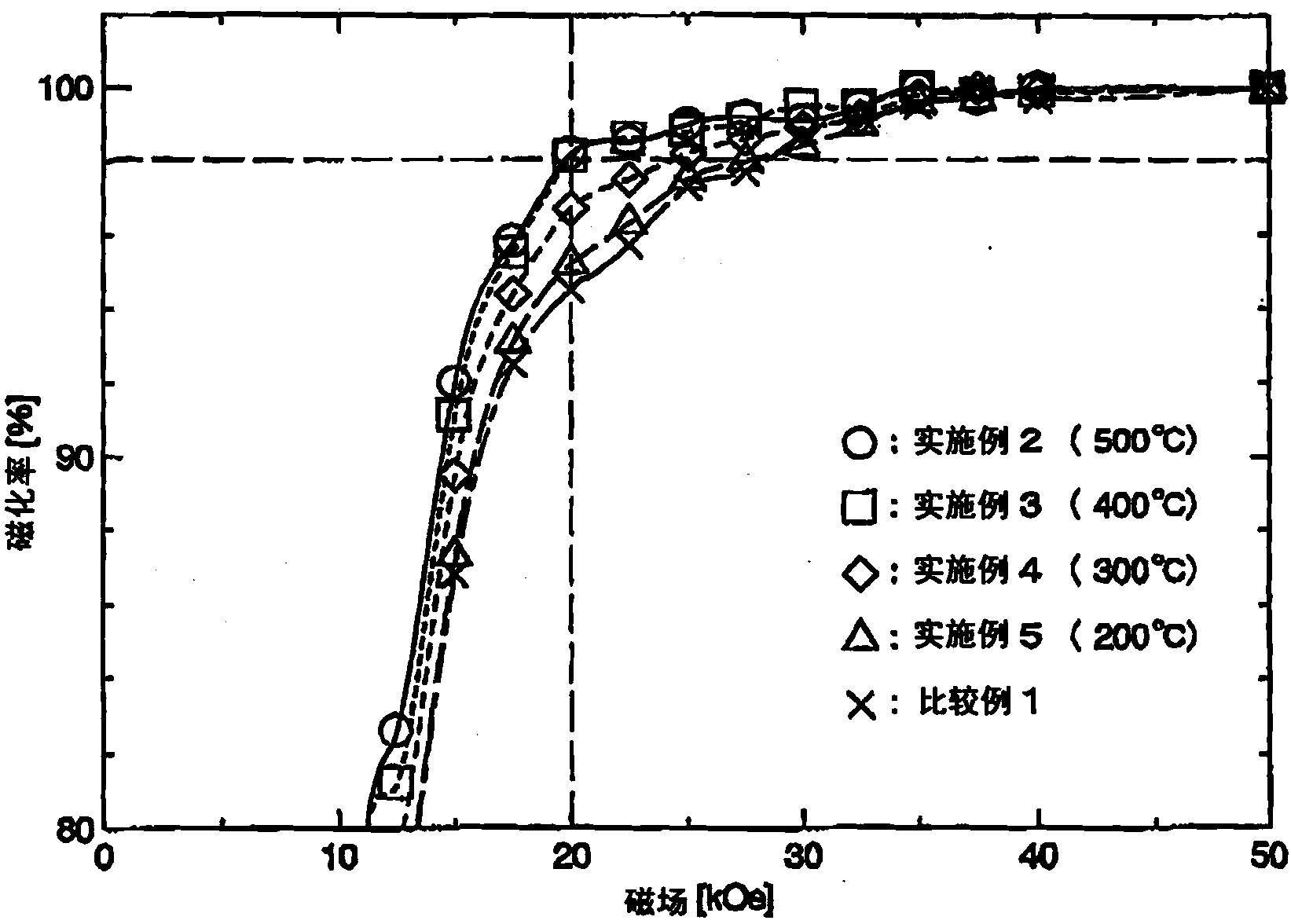

[0051] Examples of RFeB-based magnets actually manufactured using the method of the present invention are described below.

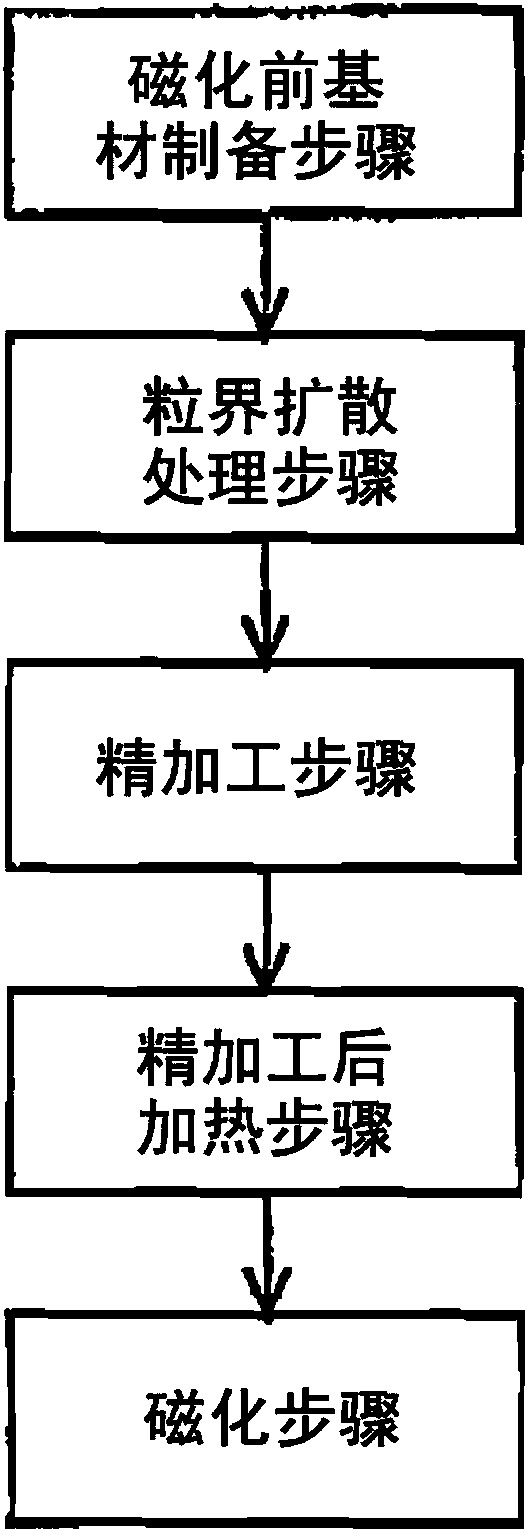

[0052] (a) Method of manufacturing the RFeB-based magnet of the example of the present invention

[0053] (a-1) Preparation steps of substrate before magnetization

[0054] In this embodiment, a sintered body manufactured by the PLP method is used as the base material before magnetization. Specifically, the base material before magnetization was manufactured by the following method.

[0055] First, a strip casting method was used to prepare Nd: 26.6% by weight, Pr: 4.7% by weight, Fe: 65.5% by weight, Co: 1.9% by weight, B: 1.0% by weight, Al: 0.2% by weight, and Cu: The raw alloy flakes with a composition of 0.1% by weight are hydrogen crushed and then pulverized using a jet mill, thereby producing raw alloy powders having (i) 3 μm and (ii) 4 μm average particle diameters. Hereinafter, the powder of (i) is referred to as "3-μm powder", and the powder of (ii) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com