Thermo-acoustic three-phase alternating current generating system driven by double-temperature-position heat source

A three-phase AC and power generation system technology, applied in the direction of mechanisms, electrical components, electromechanical devices that generate mechanical power, etc., can solve the problems of many intermediate links, low conversion efficiency, environmental pollution, etc. Low, high utilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below in conjunction with specific examples.

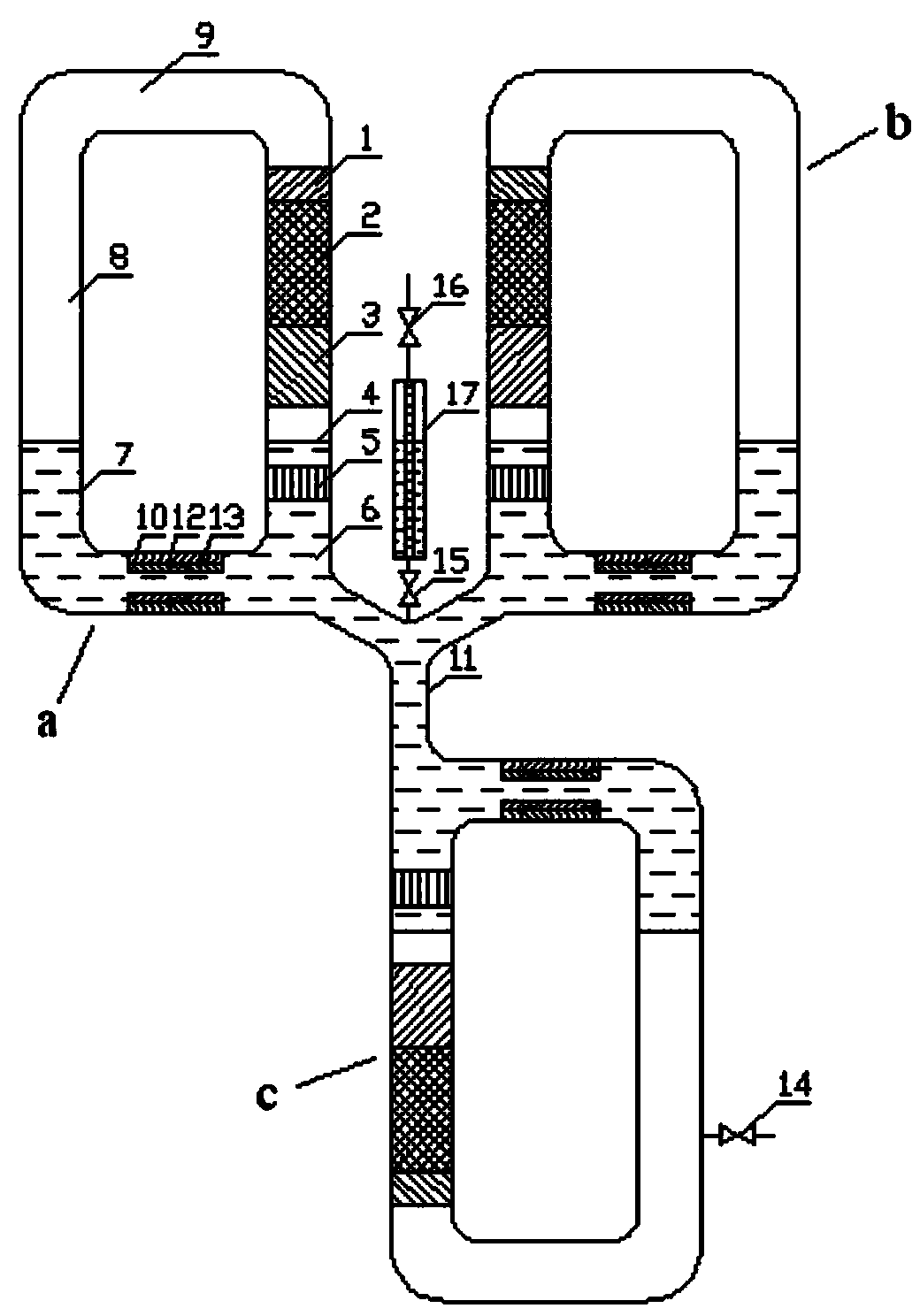

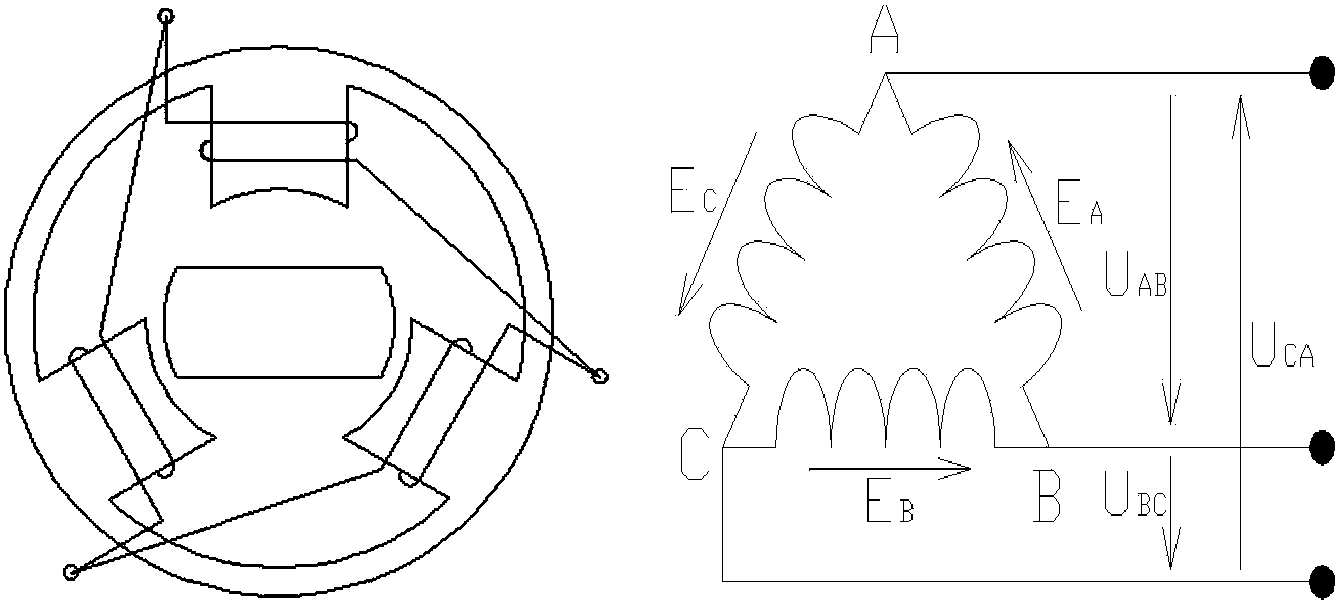

[0047] Such as figure 1 As shown, the thermoacoustic three-phase AC power generation system driven by a dual-temperature heat source includes three loop units with the same structure, which are loop unit a, loop unit b, and loop unit c. Each loop unit includes a heat Acoustic conversion device and magnetic fluid power generation device.

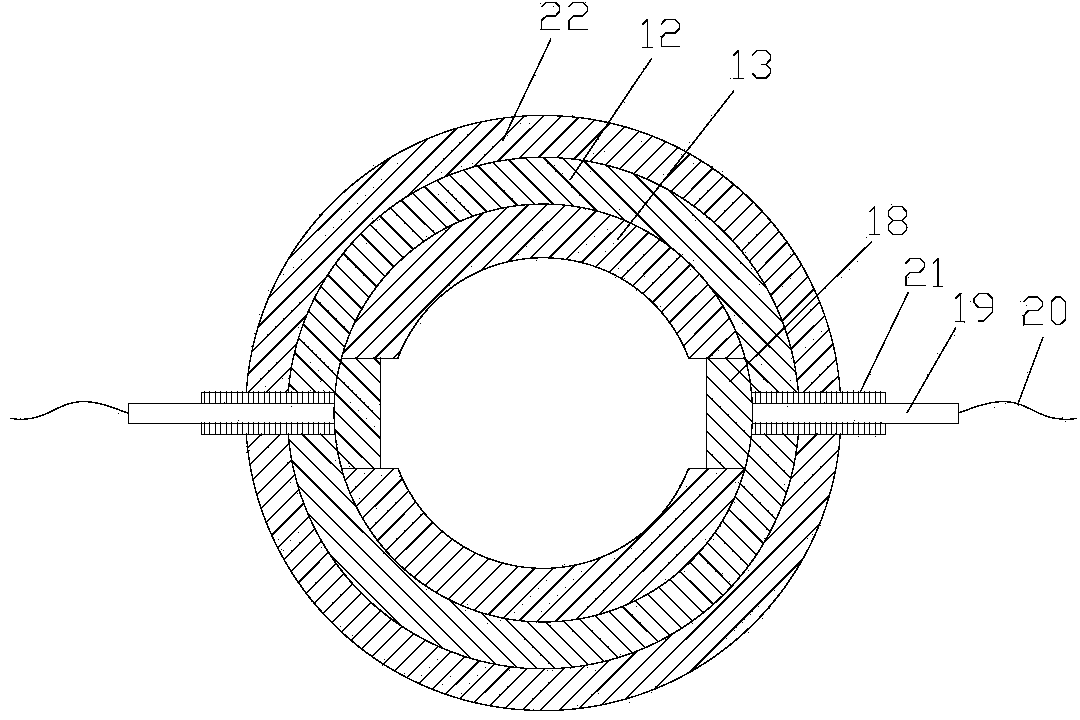

[0048] The thermoacoustic conversion device includes a high-temperature heat exchanger 1 , a regenerator 2 , a medium-temperature heat exchanger 3 , a liquid buffer pipe 4 , a room temperature heat exchanger 5 , a U-shaped pipe 7 , a feedback pipe 8 and an acoustic volume chamber 9 connected end to end. Wherein the high temperature heat exchanger 1, the regenerator 2, the medium temperature heat exchanger 3, the liquid buffer pipe 4 and the room temperature heat exchanger 5 are sequentially connected from top to bottom, and the U-shaped pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com