Air compressor heatless adsorption air drying method and modular air dryer

An air compressor and air drying technology, which is applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of many sealing points, many control pipelines, and complex structures, so as to reduce the occurrence of faults and overcome the problems of connection The effect of many parts and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

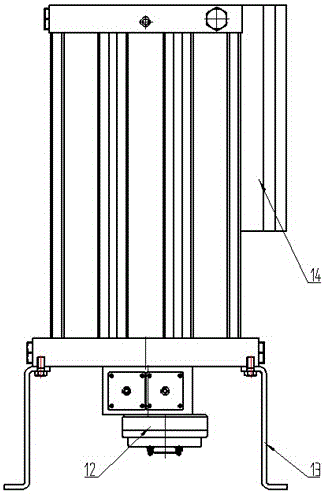

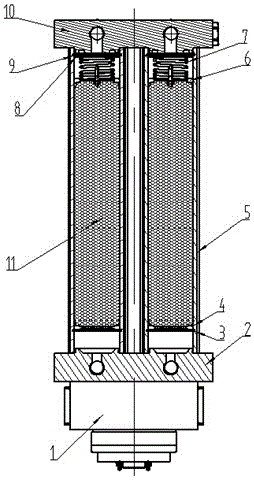

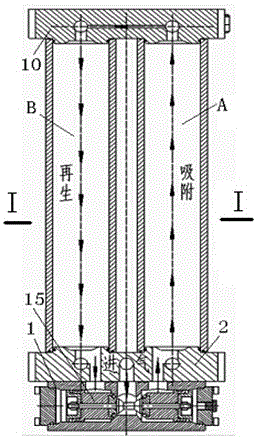

[0031] by attaching Figure 1-3 It can be seen that the present invention is a heatless adsorption air dryer for a locomotive air compressor, comprising 6 adsorption towers 5, the adsorption towers 5 are modular structures, and the upper filter group 6 and the anti-loosening spring of each adsorption tower 5 are 7. The upper positioning filter screen 8 and the positioning retainer 9 are installed on the upper inner surface of the adsorption tower 5, the lower filter combination 3 and the axial positioning retainer 4 are installed on the lower inner surface of the adsorption tower 5, and the upper filter group 6 and the lower filter combination 3 are integrated with the cylinder body of the adsorption tower 5 and the adsorption material 11 to form an adsorption tower module. The six adsorption tower modules are divided into two groups and installed between an upper cover plate 10 and a lower cover plate 2. The upper cover plate 10 and the lower cover plate 2 are respectively co...

Embodiment 2

[0038] The basic composition principle of Embodiment 2 is the same as that of Embodiment 1, except that there are 4 adsorption tower modules, and the 4 adsorption tower modules are divided into two groups, which are installed obliquely between the upper cover plate and the lower cover plate respectively. , when one group is adsorbed, the other group is regenerated. An electric control valve is provided on the lower cover plate to change the inlet or outlet channel of the adsorption tower module, so that the adsorption tower module can alternately perform adsorption or regeneration. Through the electric control valve The automatic control of the adsorption tower module makes the adsorption or regeneration work alternately.

[0039] The automatic control is to install an electric control device on the electric control valve, and the electric control valve is controlled by the electric control device to perform switching operations; the electric control device is controlled in seq...

Embodiment 3

[0042] The basic composition principle of the third embodiment is the same as that of the first embodiment, except that the adsorption tower module is installed horizontally and horizontally, and the upper cover plate and the lower cover plate at both ends of the adsorption tower module become the right cover plate and the left cover plate respectively. And the electric control valve is installed on the right cover plate, through the automatic control of the electric control valve, the adsorption tower module can perform the alternate operation of adsorption or regeneration.

[0043] The automatic control is to install an electric control device on the electric control valve, and the electric control valve is controlled by the electric control device to perform switching operations; the electric control device is controlled in sequence by a PLC controller, and the PLC controller adopts programmable logic control Technology, through the control of the dew point temperature at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com