Intelligent aquagel based on cyclodextrin functional groups, and preparation method and application thereof

A functional group, tosyl cyclodextrin technology, applied in the field of intelligent hydrogel, can solve the problems of poor mechanical properties, poor biocompatibility, slow response rate, etc., to improve mechanical properties, fast response, improve Effect of swelling and deswelling kinetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

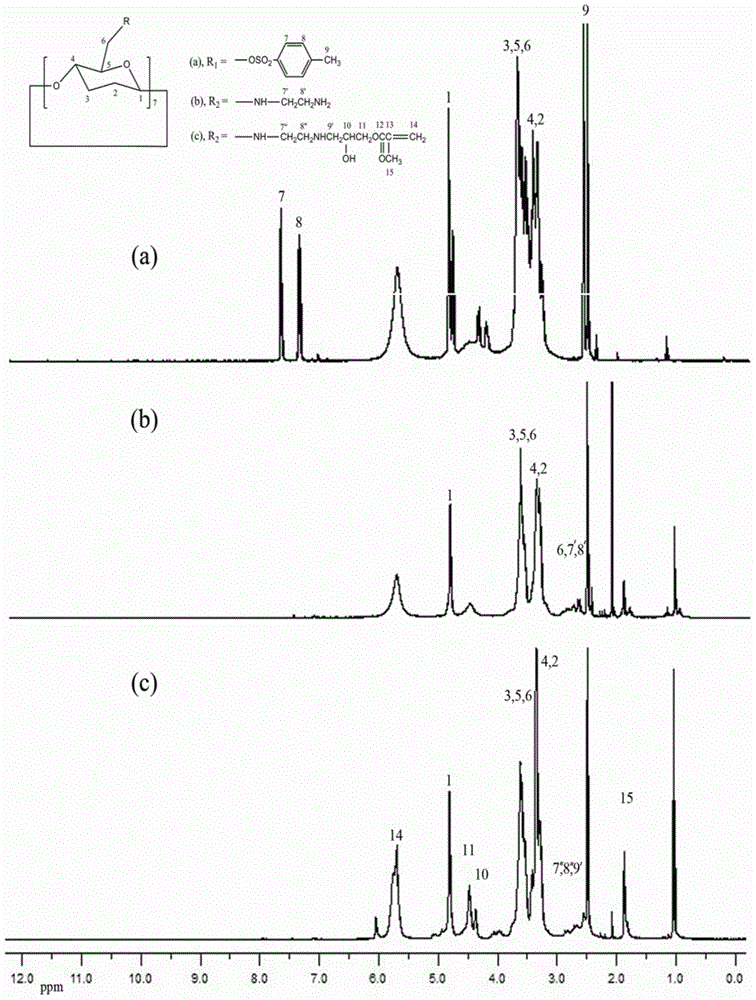

Method used

Image

Examples

Embodiment 1

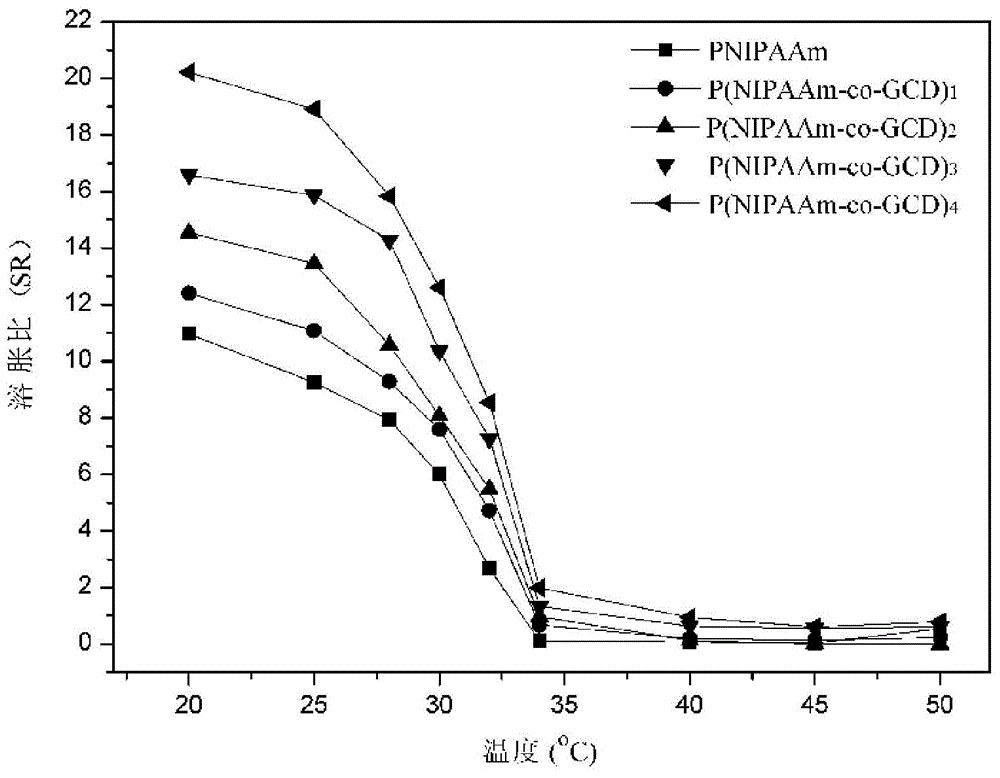

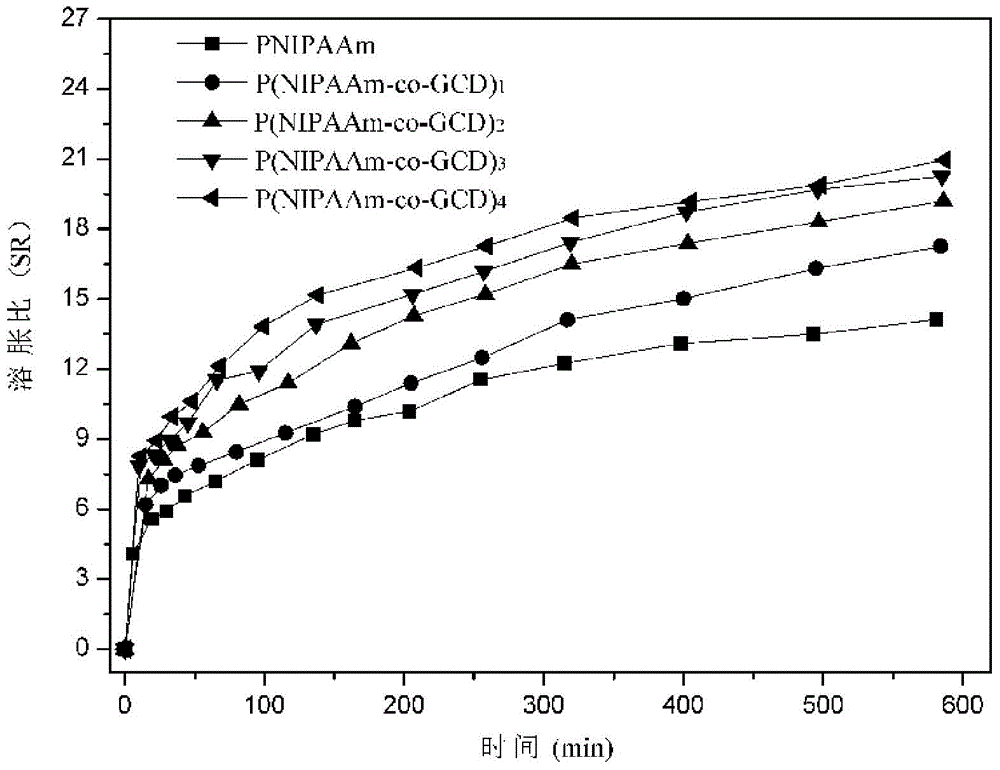

[0047] A method for preparing a poly(N-isopropylacrylamide) smart hydrogel based on cyclodextrin functional groups in this embodiment, the specific preparation steps are as follows:

[0048] Weigh 0.4g of N-isopropylacrylamide (NIPAAm), 20mg of GCD and 32mg of BIS, dissolve in 4ml of dimethyl sulfoxide, mix the raw materials uniformly by ultrasonication for 15min, then add 10mg of azobisisobutylcyanide, and then mix thoroughly by ultrasonication for 15min before freezing Thaw cycle to remove oxygen, react at 60°C for 24 hours under the protection of nitrogen, crush the reactor, soak the gel in distilled water for a week, change the water every day, remove unreacted raw materials and obtain poly(N-iso Propylacrylamide) smart hydrogel, cut into 10mm*5mm cylindrical small pieces for later use, recorded as P(NIPAAm-co-GCD) 1 .

Embodiment 2

[0050] A method for preparing a poly(N-isopropylacrylamide) smart hydrogel based on cyclodextrin functional groups in this embodiment, the specific preparation steps are as follows:

[0051] Weigh 0.4g of N-isopropylacrylamide (NIPAAm), 40mg of GCD and 32mg of BIS, dissolve it in 4ml of dimethyl sulfoxide, mix the raw materials uniformly by ultrasonication for 15min, then add 10mg of azobisisobutylcyanide, and then mix thoroughly by ultrasonication for 15min before freezing Thaw cycle to remove oxygen, react at 60°C for 24 hours under the protection of nitrogen, crush the reactor, soak the gel in distilled water for a week, change the water every day, remove unreacted raw materials and obtain poly(N-iso Propylacrylamide) smart hydrogel, cut into 10mm*5mm cylindrical small pieces for later use, recorded as P(NIPAAm-co-GCD) 2 .

Embodiment 3

[0053] A method for preparing a poly(N-isopropylacrylamide) smart hydrogel based on cyclodextrin functional groups in this embodiment, the specific preparation steps are as follows:

[0054] Weigh 0.4g of N-isopropylacrylamide (NIPAAm), 60mg of GCD and 32mg of BIS and dissolve it in 4ml of dimethyl sulfoxide, mix the raw materials uniformly by ultrasonication for 15min, then add 10mg of azobisisobutylcyanide, and then 15min of ultrasonication to fully mix and freeze Thaw cycle to remove oxygen, react at 60°C for 24 hours under the protection of nitrogen, crush the reactor, soak the gel in distilled water for a week, change the water every day, remove unreacted raw materials and obtain poly(N-iso Propylacrylamide) smart hydrogel, cut into 10mm*5mm cylindrical small pieces for later use, recorded as P(NIPAAm-co-GCD) 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com