A heat storage heat exchanger and a heat storage heat exchange device

A technology for heat storage heat exchangers and heat exchange devices, which is applied in the types of heat exchangers, indirect heat exchangers, heat storage equipment, etc., and can solve problems such as failure to improve comprehensive energy saving effects, difficult maintenance, and uneven fluid distribution , to achieve the effect of good heat transfer and flow comprehensive performance, good use effect, and fast heat storage and discharge speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

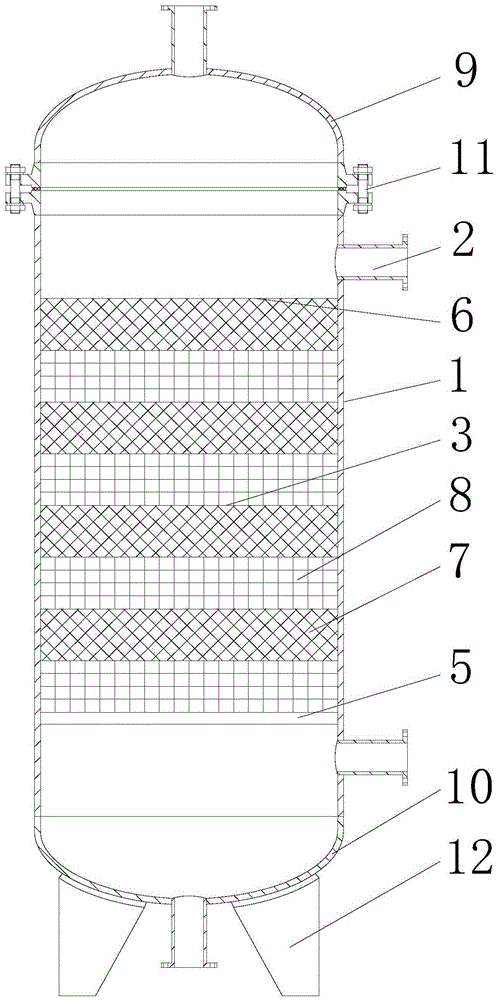

[0029] A heat storage heat exchanger, comprising a tank body 1, the upper and lower sides of the tank body 1 are respectively provided with gas inlet and outlet conduits 2, and a heat storage bed 3 and a heat storage bed fixing structure are arranged between the upper and lower gas inlet and outlet conduits in the tank body 1 The heat storage bed 3 is fixed in the tank body 1 through the heat storage bed fixing structure. Specifically, the heat storage bed fixing structure includes a heat storage medium support plate 5 and a heat storage medium pressure ring 6. The heat storage bed 3 is arranged on the Between the heat medium support plate 5 and the heat storage medium pressure ring 6 .

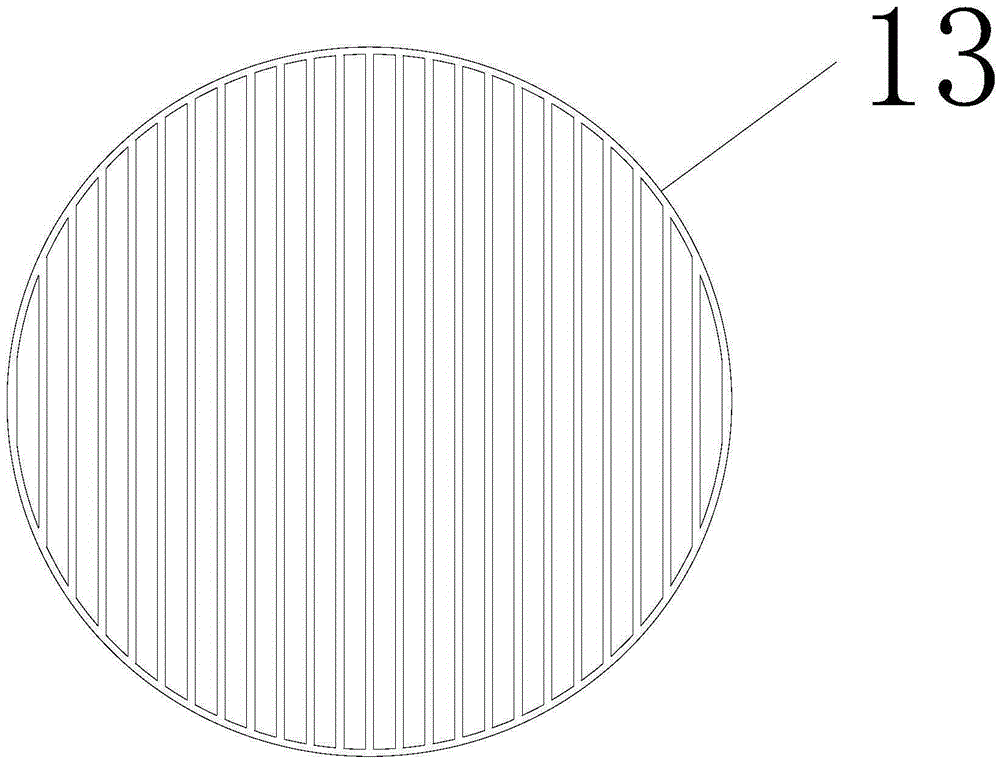

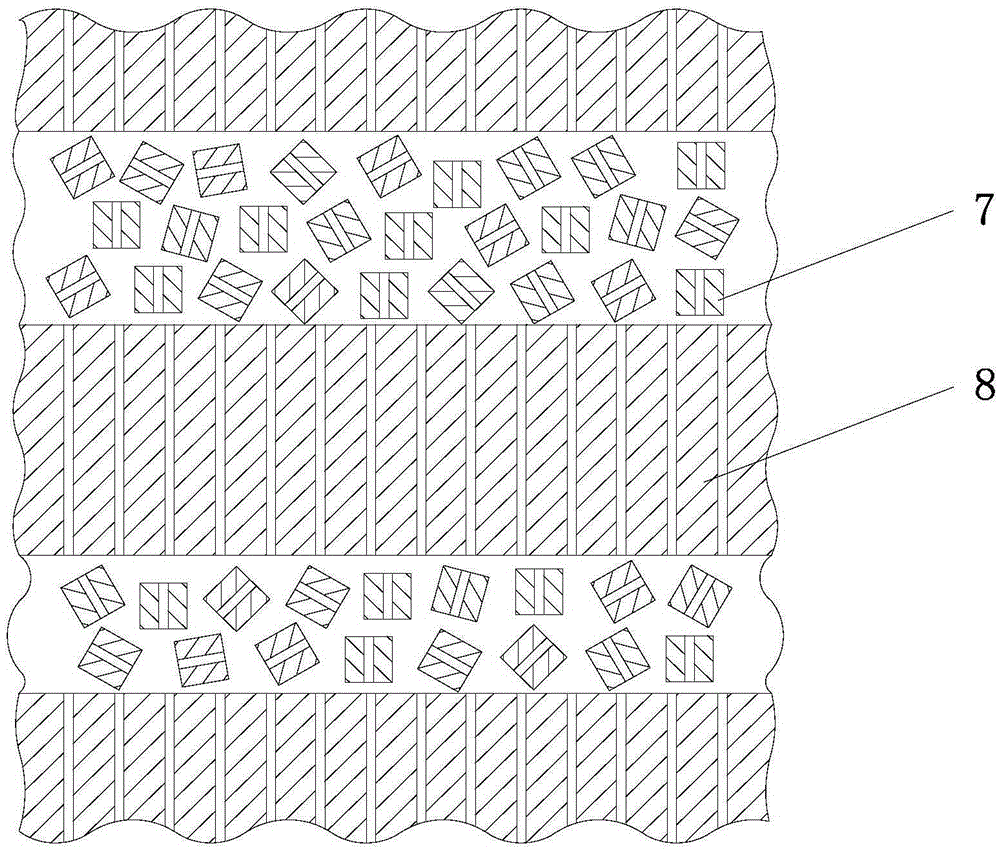

[0030] The heat storage bed 3 includes a stacked scattered heat storage medium layer 7 and a regular heat storage medium layer 8. The scattered heat storage medium layer 7 is stacked together by a plurality of scattered heat storage media. A first flow channel is formed between the media, and...

Embodiment 2

[0036] A heat storage and heat exchange device, including a heat storage heat exchanger of the first two embodiments, an intelligent controller 14, a hot gas pipeline 15, and an air pipeline 16. The gas inlet and outlet conduits 2 include hot gas inlet and outlet and air The inlet and outlet, the inlet and outlet of hot air and the inlet and outlet of air are respectively provided with valves. Specifically, the valves are pneumatic valves. The inlet and outlet of hot air include a hot air inlet 21 and a hot air outlet 22. On the body 1, the air inlet and outlet include an air inlet 23 and an air outlet 24, and the air inlet 23 and the air outlet 24 are respectively arranged on the tank body 1 up and down. The hot gas inlet 21 , the hot gas outlet 22 , the air inlet 23 and the air outlet 24 are provided with the pneumatic valves. The output port of the hot gas pipeline 15 is provided with a hot gas outlet temperature sensor 25, the output port of the air pipeline 16 is provided...

Embodiment 3

[0045] This embodiment is controlled by setting the alternate heat storage and heat release time of the two heat storage heat exchangers, the details are as follows: the regular heat storage medium layer uses a honeycomb ceramic heat storage body, and its specification is Φ4mm honeycomb round holes, and the heat storage is scattered The medium layer uses thick-walled ceramic Pall rings with a specification of Φ16x16x5mm. The two selected heat storage media are alternately stacked in the tank. The height of a single regular heat storage medium layer is 40mm, and the height of a single scattered heat storage medium layer is 60mm, the regular heat storage medium layer and the random heat storage medium layer are 5 layers each. Both tanks have a diameter of 500mm and a height of 1200mm. The valve switching time is set to 1min through the intelligent controller, that is, the alternate heat storage and heat release process of the two heat storage heat exchangers is 1min, and the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com