A method for the automated construction of stable electrocatalytic bacterial biofilms

A bacterial biofilm and automatic construction technology, applied in the direction of biochemical fuel cells, etc., can solve the problems of poor bearing capacity, low electrocatalytic efficiency, and small limit operating current, and achieve improved catalytic activity, strong catalytic activity, and large catalytic current. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

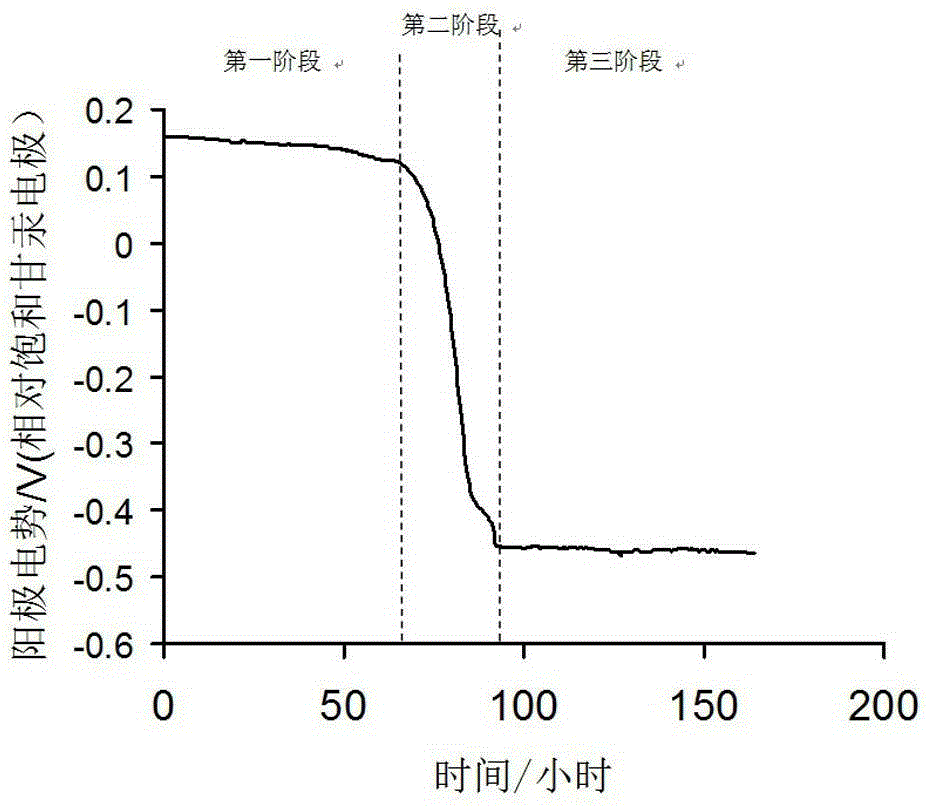

[0035] The present invention automatically constructs the method for stable electrocatalytic bacterial biofilm, comprises the following steps successively:

[0036] (1) Assemble the microbial electrochemical reactor, which includes an anode chamber equipped with an anode plate and a cathode chamber equipped with a cathode plate.

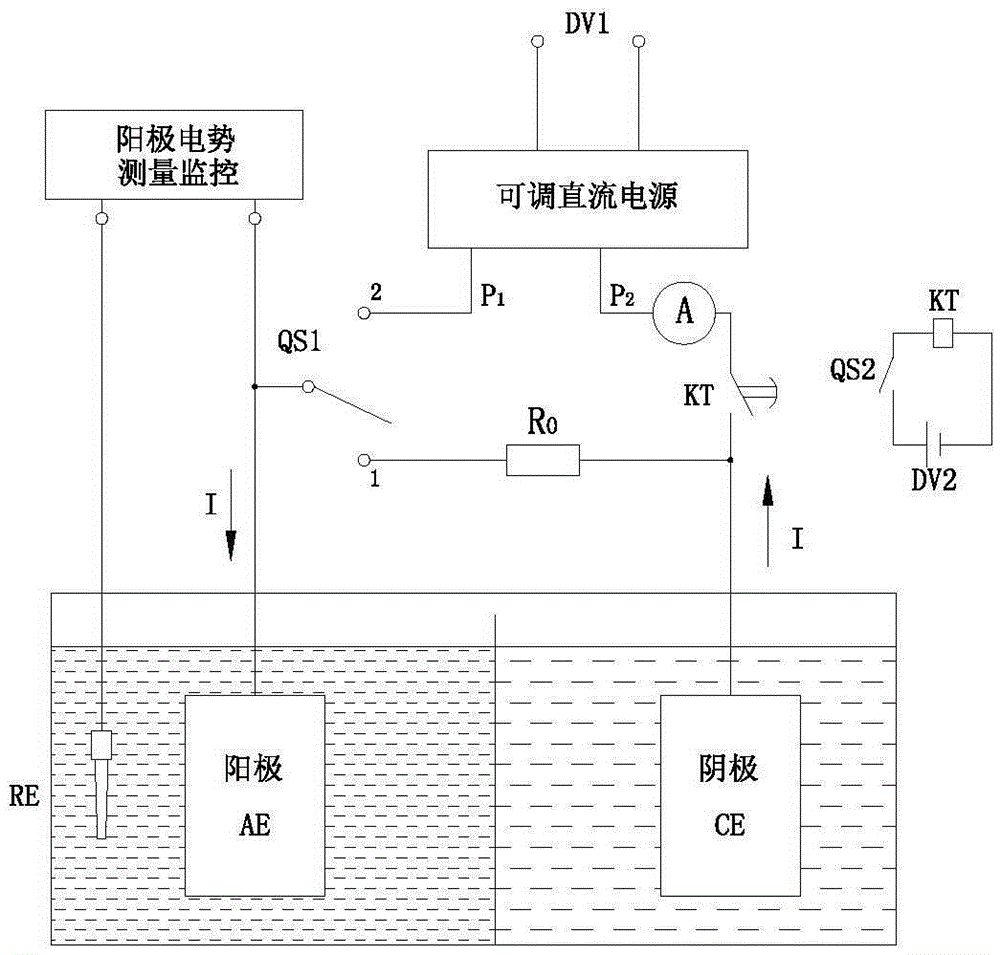

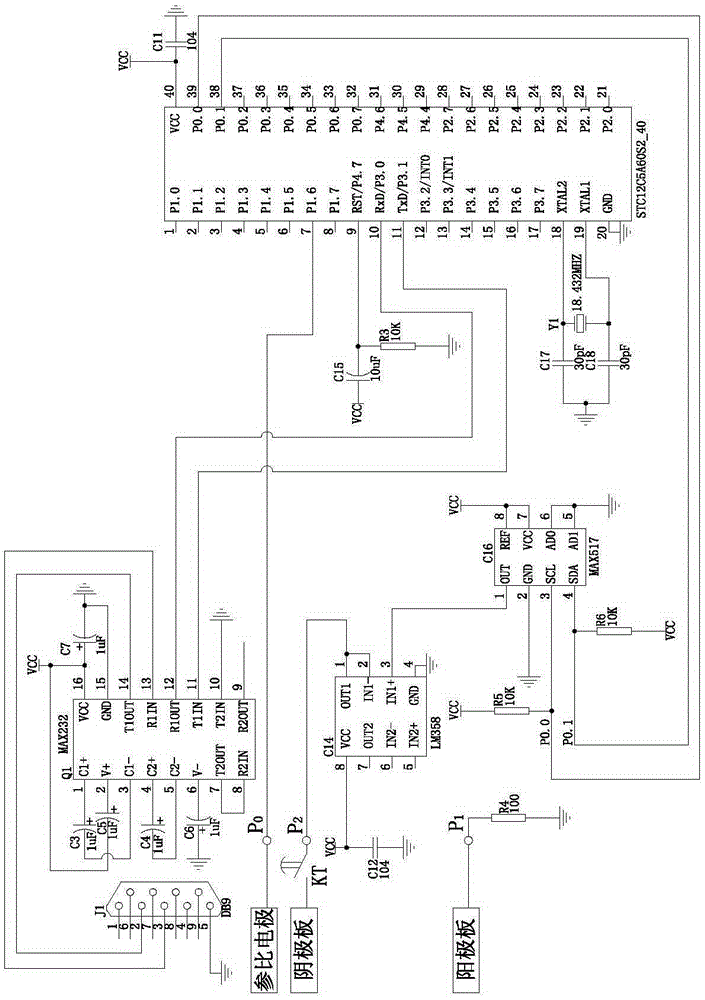

[0037] ⑵ if figure 1 , figure 2 Connect circuit components as shown.

[0038] (3) Pre-start the microbial anode, inject bacterial growth medium solution into the anode chamber of the microbial electrochemical reactor to immerse the anode, inject cathodic solution into the cathode chamber of the microbial electrochemical reactor to immerse the cathode, and then inoculate the anode chamber with The microbial source of bacteria, and then turn the selection switch QS1 to connect with the first selection end so that the anode passes through the fixed resistance R 0 It is electrically connected to the cathode to pre-start the microbial anode.

[0039]...

Embodiment 2

[0046] The present invention automatically constructs the method for stable electrocatalytic bacterial biofilm, comprises the following steps successively:

[0047] (1) Assemble the microbial electrochemical reactor, which includes an anode chamber equipped with an anode plate and a cathode chamber equipped with a cathode plate.

[0048] ⑵ if figure 1 , figure 2 Connect circuit components as shown.

[0049] (3) Pre-start the microbial anode, inject bacterial growth medium solution into the anode chamber of the microbial electrochemical reactor to immerse the anode, inject cathodic solution into the cathode chamber of the microbial electrochemical reactor to immerse the cathode, and then inoculate the anode chamber with Then turn the selection switch QS1 to connect with the first selection terminal so that the anode is electrically connected to the cathode through the fixed resistance R0, and the microbial anode is pre-started.

[0050] The raw material composition and weig...

Embodiment 3

[0057] The present invention automatically constructs the method for stable electrocatalytic bacterial biofilm, comprises the following steps successively:

[0058] (1) Assemble the microbial electrochemical reactor, which includes an anode chamber equipped with an anode plate and a cathode chamber equipped with a cathode plate.

[0059] ⑵ if figure 1 , figure 2 Connect circuit components as shown.

[0060] (3) Pre-start the microbial anode, inject bacterial growth medium solution into the anode chamber of the microbial electrochemical reactor to immerse the anode, inject cathodic solution into the cathode chamber of the microbial electrochemical reactor to immerse the cathode, and then inoculate the anode chamber with The microbial source of bacteria, and then turn the selection switch QS1 to connect with the first selection end so that the anode passes through the fixed resistance R 0 It is electrically connected to the cathode to pre-start the microbial anode.

[0061]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com