A castable powder processing device

A powder processing and castable technology, which is applied in the direction of centrifuge, liquid separation agent, solid separation, etc., can solve the problems affecting the performance of refractory brick products, iron is difficult to handle, etc., to reduce physical injuries and reduce dust , Improve the effect of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

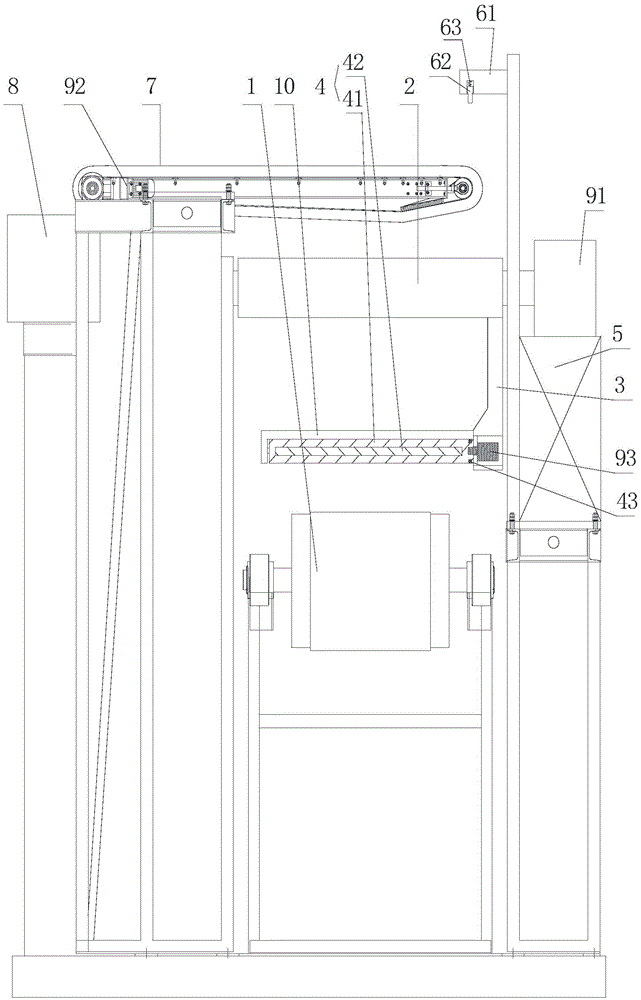

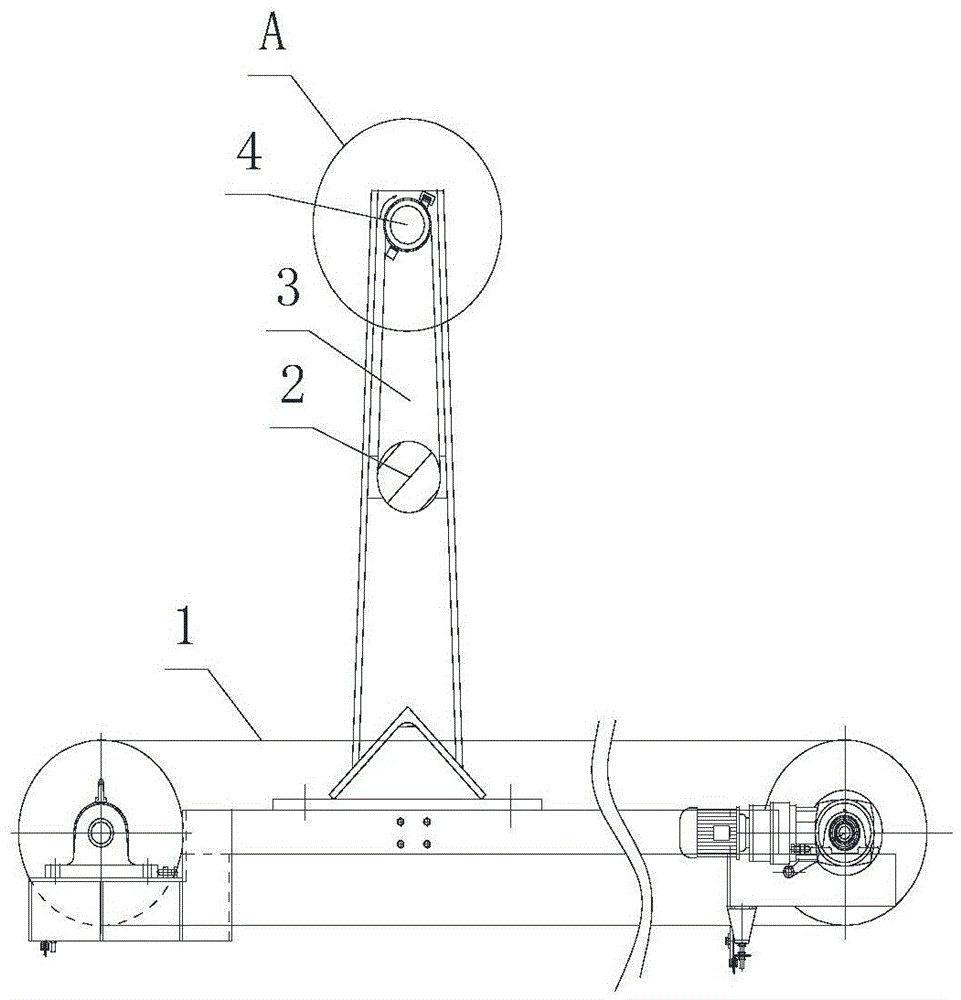

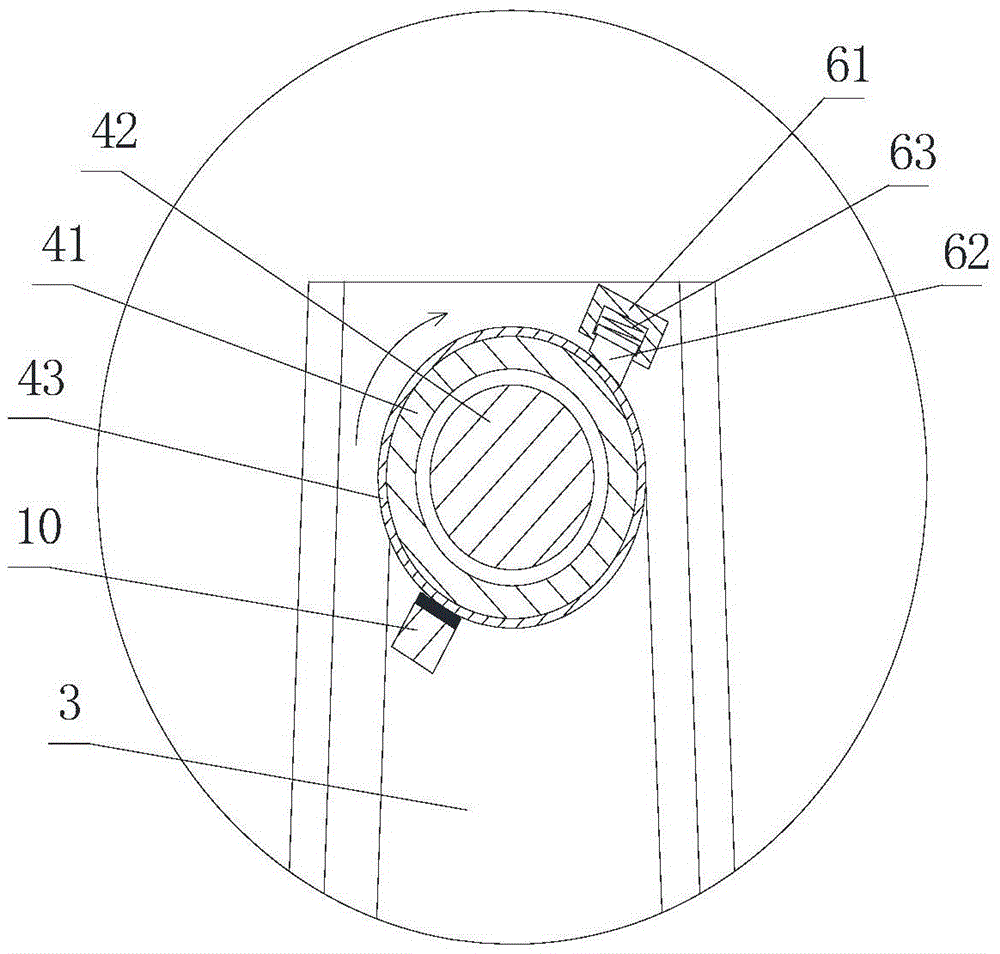

[0015] Such as Figures 1 to 4 As shown, a castable powder processing device includes a conveyor belt I1 for conveying castables, a rotating shaft 2, a magnetic separation shaft 4 and a control system 5, the rotating shaft 2 and the magnetic separation shaft 4 are located above the conveyor belt I1, and the rotating shaft 2 The axial direction of the conveyor belt I1 is perpendicular to the conveying direction of the conveyor belt I1. The rotating shaft 2 is connected to the driving motor 91 and driven to rotate axially by the driving motor 91. The driving motor 91 is electrically connected to the control system 5. The magnetic separation shaft 4 is arranged parallel to the rotating shaft 2. The rotating shaft 2 Connect with the magnetic selection shaft 4 through the connecting rod 3, the magnetic selection shaft 4 includes a shaft cylinder 41 and an electromagnet assembly 42 inside the shaft cylinder 41, a pressure sensor 43 is arranged on the outer wall of the shaft cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com