Method for Reducing the Band Break Rate of Laser Welding of Chilled Phosphorus-Containing IF Steel

A laser welding, laser technology, applied in laser welding equipment, process efficiency improvement, welding equipment and other directions, can solve problems such as ineffectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, the thickness of the chilled phosphorus-containing IF steel plate is 0.8 mm, the power of the laser welder is 2000 W, and the welding speed is 3 m / min. The length of the high-frequency induction coil used for heat treatment in the weld area after welding is 100mm longer than the weld, the heat treatment time is 1 minute, and the heat treatment temperature is 1100°C.

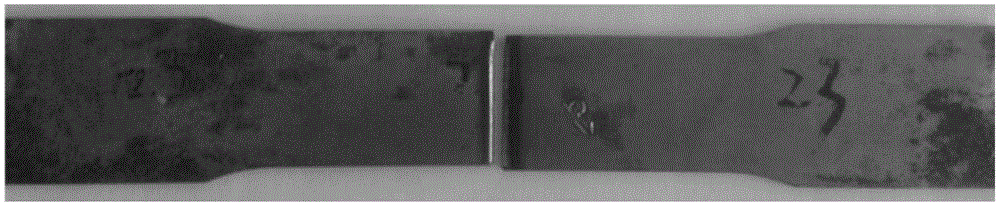

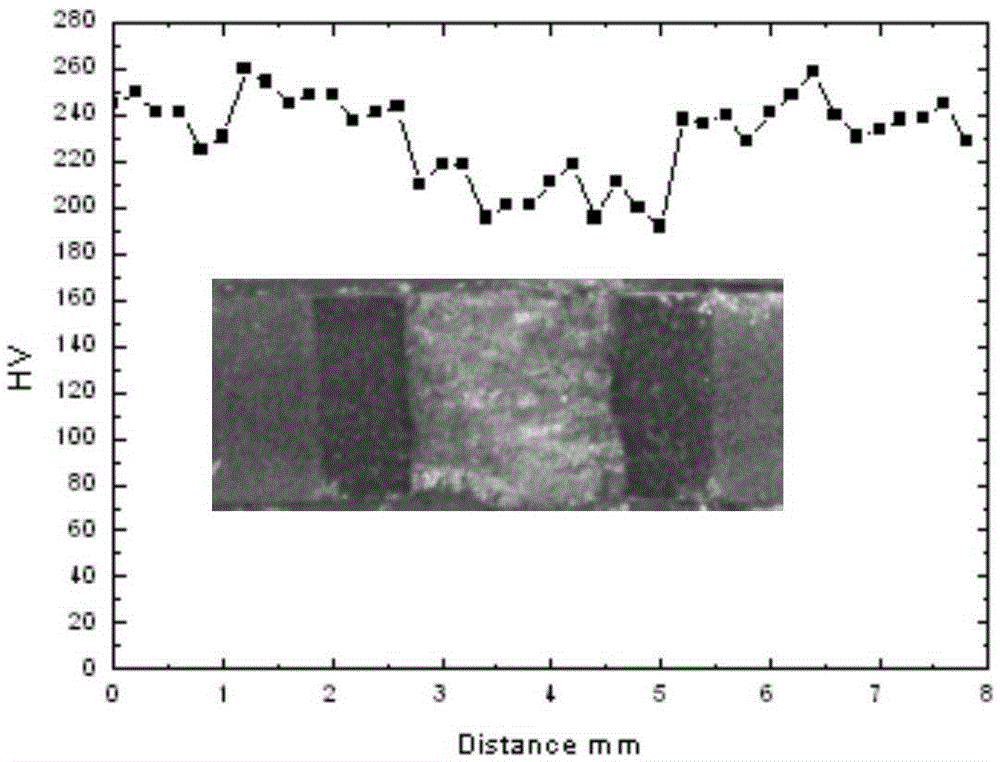

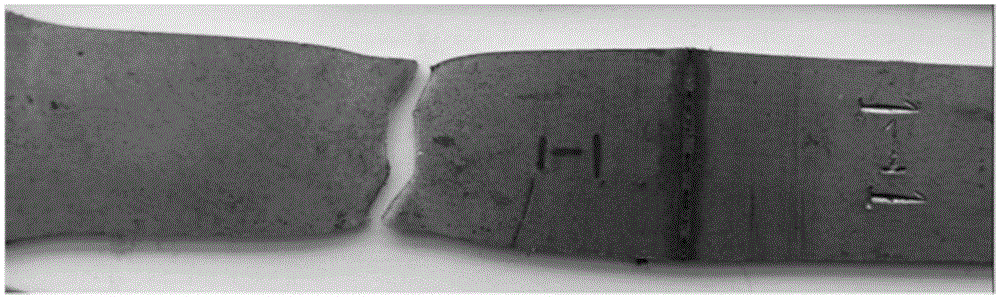

[0022] Metallographic testing results show that the hardness of the weld is 195HV, and the hardness of the base metal is 155HV (see Figure 4 ), the microhardness of the weld is significantly higher than that of the base metal; tensile fracture occurs in the base metal (see image 3 ), the weld strength is higher than that of the base metal. The number of repeated bending fractures of the weld was 19 times, and the number of repeated bending fractures of the base metal was 18 times.

Embodiment 2

[0024] In this embodiment, the thickness of the chilled phosphorus-containing IF steel plate is 1.4 mm, the power of the laser welder is 3000 W, and the welding speed is 3 m / min. The length of the high-frequency induction coil used for heat treatment in the weld area after welding is 50 mm longer than that of the weld, the heat treatment time is 2 minutes, and the heat treatment temperature is 1000 °C.

[0025] The metallographic test results show that the hardness of the weld is 180HV, the hardness of the base metal is 140HV, the microhardness of the weld is significantly higher than that of the base metal, the tensile fracture occurs in the base metal, and the strength of the weld is higher than that of the base metal. The number of times when the weld was repeatedly bent and broken was 20 times, and the number of times when the base metal was repeatedly bent and broken was 17 times.

Embodiment 3

[0027] In this embodiment, the thickness of the chilled phosphorus-containing IF steel plate is 1.6mm, the power of the laser welder is 4000W, and the welding speed is 5m / min. Equal length, the heat treatment time is 3 minutes, and the heat treatment temperature is 800°C.

[0028] Metallographic testing results show that the hardness of the weld seam is 175HV, and the hardness of the base metal is 135HV. The microhardness of the weld seam is significantly higher than that of the base metal; the tensile fracture occurs in the base metal, and the strength of the weld seam is higher than that of the base metal. The number of times when the weld was repeatedly bent and broken was 20 times, and the number of times when the base metal was repeatedly bent and broken was 16 times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com