Super-heavy functional masterbatch, plastic product based on the masterbatch and method for producing the plastic product by rotational molding

A technology for functional masterbatches and plastic products, applied in coating and other directions, can solve the problems of increased processing difficulty, decreased material performance, increased cost, etc., and achieves the effect of low adhesion performance, appropriate melting point temperature difference, and saving additives.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

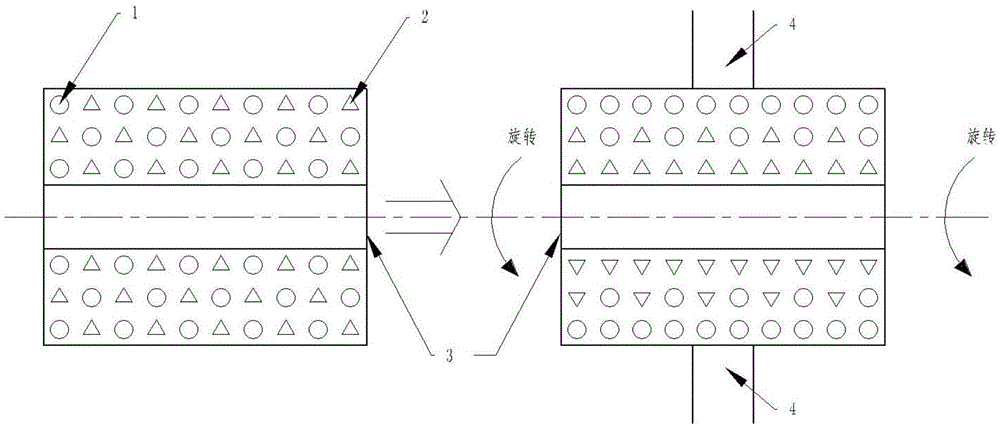

[0041] The method for preparing the plastic product based on the super-heavy functional masterbatch by rotational molding of the present invention comprises the following steps:

[0042] a), select the raw material of the overweight functional masterbatch according to the proportion and prepare the overweight functional masterbatch;

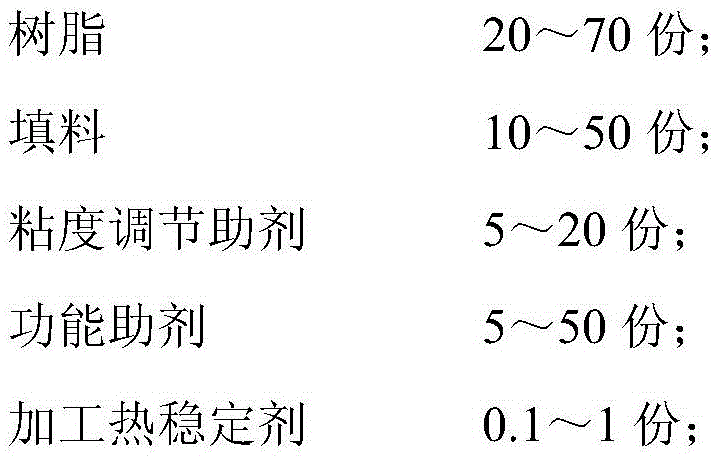

[0043] The super-heavy functional masterbatch raw materials and proportions selected in this example are: 40 parts of PP resin, 30 parts of barium sulfate, 24 parts of graphite, 5 parts of EBS, 0.5 parts of antioxidant, and 0.5 parts of polyol wax; The preparation method of the functional masterbatch is as follows: PP resin, BaSO4, graphite, EBS, antioxidant and polyol wax are uniformly mixed by a high-speed mixer, melted, blended, extruded, stretched, water-cooled, pelletized, and dried , that is super heavy wear-resistant masterbatch;

[0044] b), select base plastic and super-heavy functional masterbatch according to the proportioning;

[00...

Embodiment 2

[0052] The method for preparing the plastic product based on the super-heavy functional masterbatch by rotational molding of the present invention comprises the following steps:

[0053] a), select the raw material of the overweight functional masterbatch according to the proportion and prepare the overweight functional masterbatch;

[0054] The raw materials and proportions of the super-heavy functional masterbatch selected in this embodiment are: 50 parts of PP resin, BaSO 4 20 parts, 24 parts of graphite, 5 parts of EBS, 0.5 parts of antioxidant, 0.5 parts of polyol wax;

[0055] The method for preparing the super-heavy functional masterbatch in this embodiment is the same as that in Example 1;

[0056] b), select base plastic and super-heavy functional masterbatch according to the proportioning;

[0057] The base material selected in this embodiment is PE, and the mass ratio of the selected PE to the functional masterbatch is 1:1;

[0058] c), placing the raw material s...

Embodiment 3

[0064]The method for preparing the plastic product based on the super-heavy functional masterbatch by rotational molding of the present invention comprises the following steps:

[0065] a), select the raw material of the overweight functional masterbatch according to the proportion and prepare the overweight functional masterbatch;

[0066] The raw materials and proportions of the super-heavy functional masterbatch selected in this embodiment are: 45 parts of PP resin, BaSO 4 20 parts, 29 parts of conductive carbon black, 5 parts of EBS, 0.5 parts of antioxidant, 0.5 parts of polyol wax;

[0067] The method for preparing the super-heavy functional masterbatch in this embodiment is the same as that in Example 1;

[0068] b), select base plastic and super-heavy functional masterbatch according to the proportioning;

[0069] The base material selected in this embodiment is PE, and the mass ratio of the selected PE to the functional masterbatch is 1:1;

[0070] c), placing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com