Coating for inner surface of aluminium food packaging container and manufacturing method thereof

A food packaging container and production method technology, applied in anti-corrosion coatings, polyester coatings, coatings, etc., can solve the problems of water-based coatings being easy to freeze, difficult to implement, inconvenient in transportation and production, and achieve the effect of strong anti-freezing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

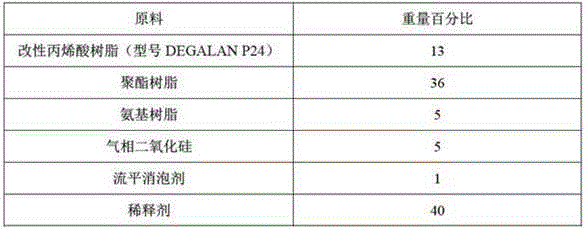

[0027] Embodiment 1, the raw materials used in the inner surface coating of a kind of aluminum food packaging container are as follows:

[0028]

Embodiment 2

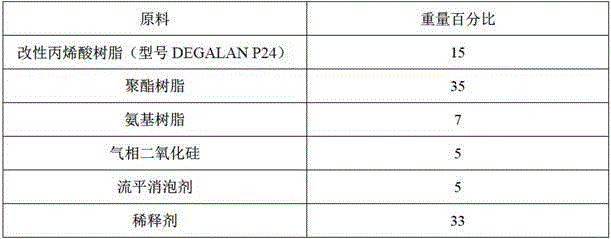

[0029] Embodiment 2, the raw materials used for the inner surface coating of a kind of aluminum food packaging container are as follows:

[0030]

Embodiment 3

[0031] Embodiment 3, the raw materials used for the inner surface coating of a kind of aluminum food packaging container are as follows:

[0032]

[0033] Following is the performance of the coating prepared according to embodiment 1 and the national standard physical and chemical index contrast:

[0034]

[0035] Following is the performance contrast of the ICI46900 coating that the performance of the coating that makes according to embodiment 1 and Taiwan ICI company produces:

[0036]

[0037] It can be seen that the production process and quality of the product of the present invention meet the national standard for water-based modified epoxy resin coatings on the inner wall of pop cans (this standard is applicable to all-aluminum or steel coatings that directly contact beer, carbonated beverages, tea beverages, coffee and energy sports drinks). The anti-corrosion coating on the inner wall of the two-piece tank), and in comparison with similar products in the mark...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com