Multi-layer upright tower type duff dust and oil shale distillation plant with stirring function and process

A technology of oil shale and dry distillation, which is applied in special forms of dry distillation, petroleum industry, coke oven, etc., can solve the problems of low energy utilization rate, achieve the effect of reducing post-treatment gas volume, reducing heat load, and reducing pyrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

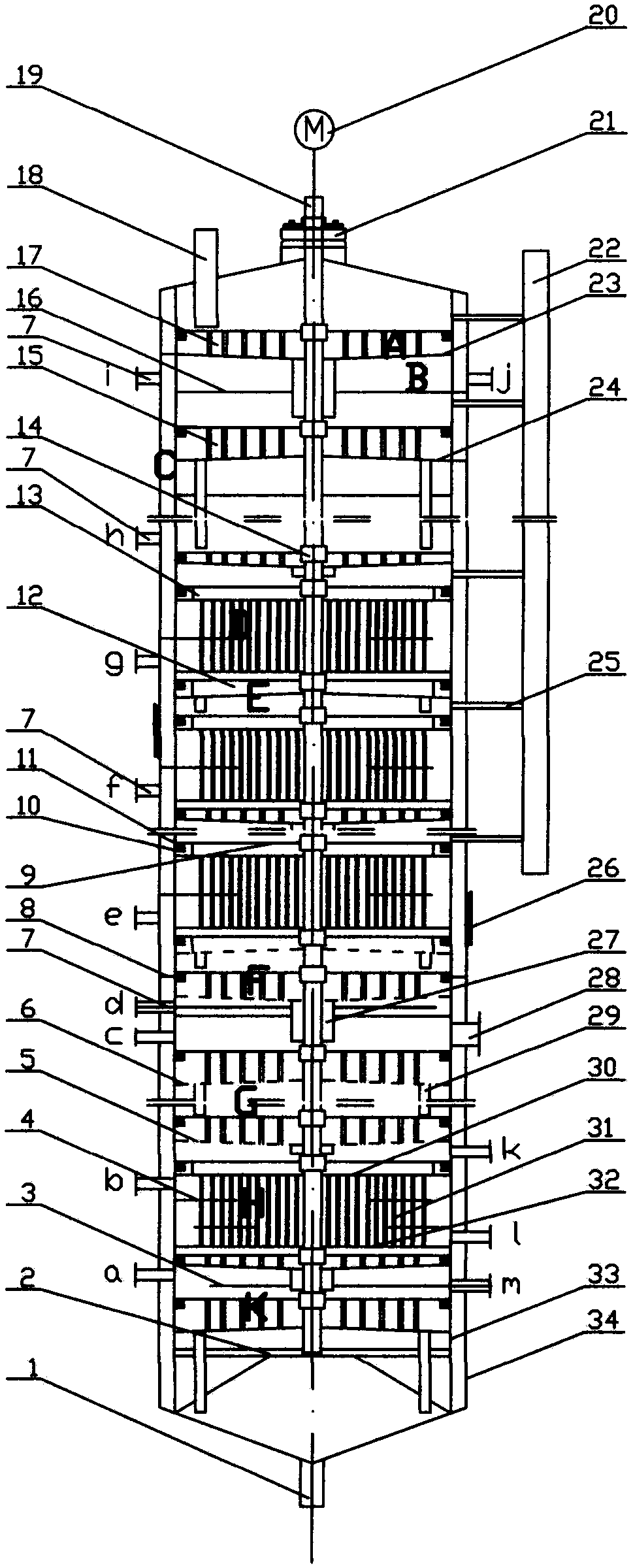

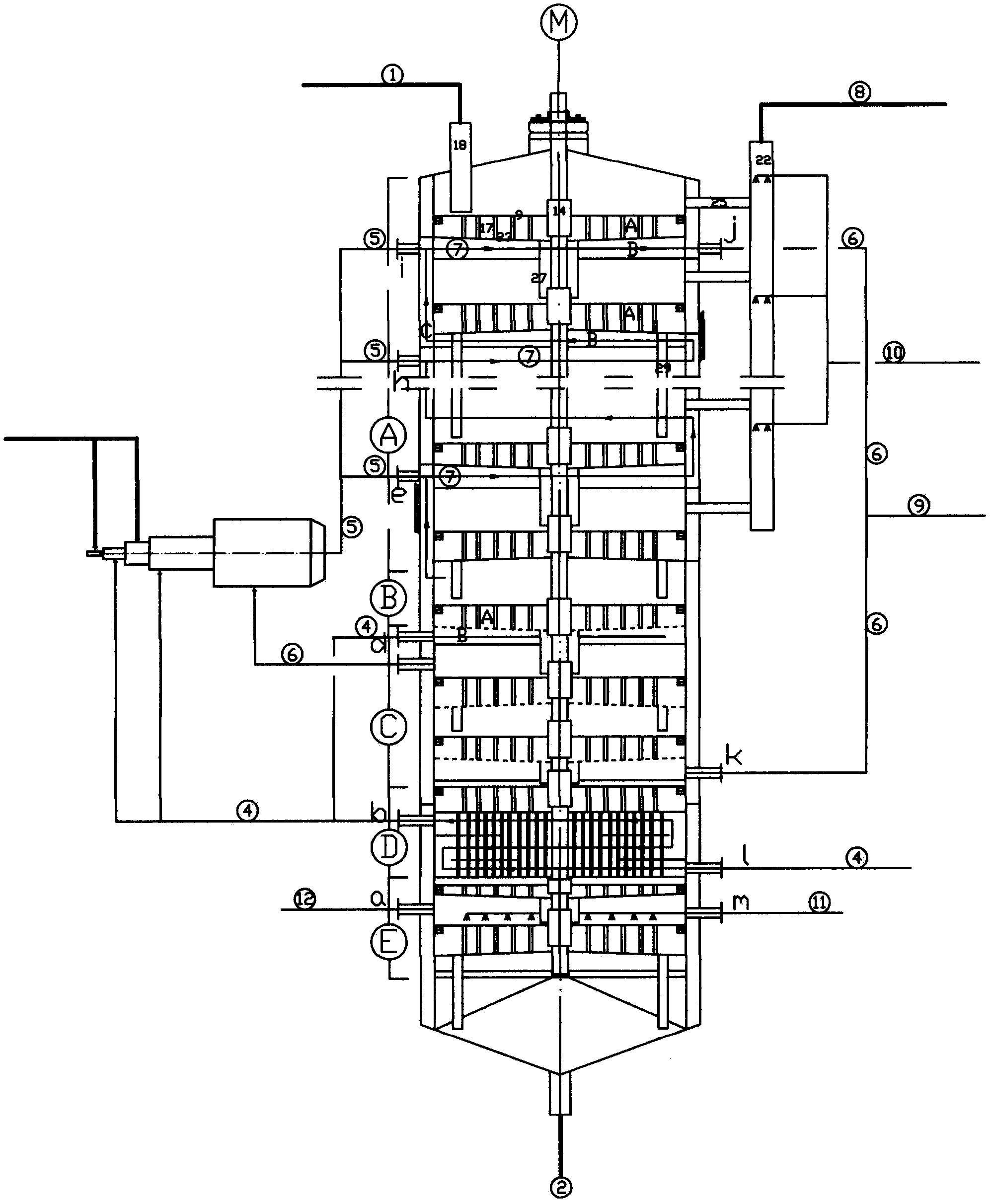

[0019] Embodiment 1: select particle diameter figure 2 process flow.

[0020] The fine coal enters the tower from the sealed feeding pipe 18, and three stirring arms 9 are arranged on the stirring shaft sleeve 14, and the high temperature and wear-resistant material groups are installed on the stirring arms 9. Propelled from the outside to the inside, the I-type sealed drop pipe 27 on this layer is set in a circular tube shape, the upper end of the tube is flush with the dry distillation layer, and the lower end passes through the heating layer B, above the heating layer B is the upper dry distillation and drying layer A, set up a high temperature wear-resistant layer, a metal plate layer in turn, and a partition plate 16 with the lower retort layer below, and heat storage materials or heating pipes inside the heating chamber B, such as heat storage ceramics, mixed hot gas ⑦ by purified Retort gas and air are combusted, combustion gas ⑤ is introduced from i and channel C, mixe...

Embodiment 2

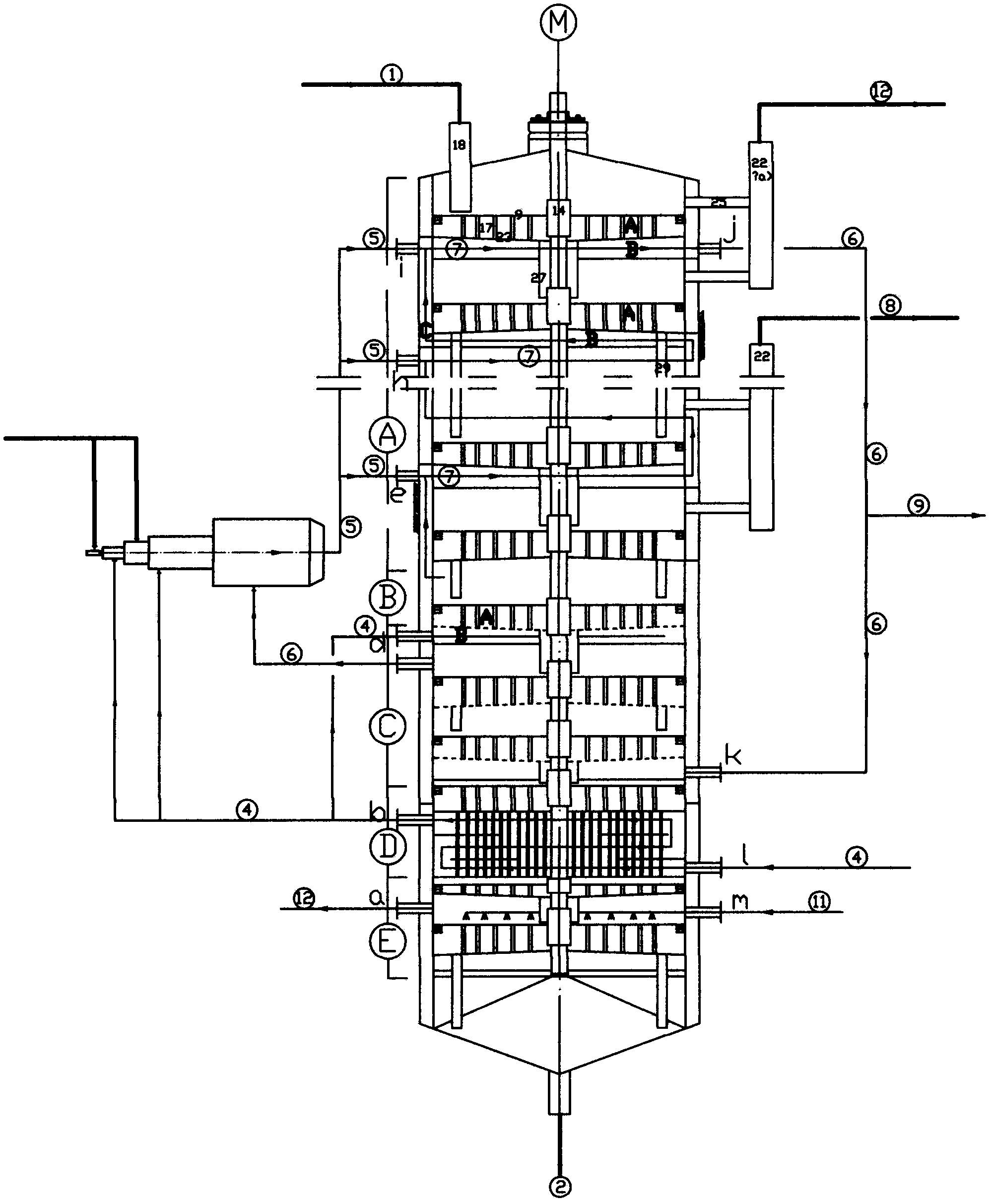

[0021] Embodiment 2: choose particle diameter image 3 process flow.

[0022] For the fine coal with high moisture content, the amount of moisture produced by drying is relatively large, and the gas collection pipe is set independently to reduce the processing load of the dry distillation gas in the later stage. To recover heat and water, the dry distillation layer A starts from the fourth layer, and the temperature is gradually increased from 105-550 ° C. The drying layer and the dry distillation layer are isolated by sealing in the downcomer. Other processes are the same as in embodiment 1.

Embodiment 3

[0023] Embodiment 3: choose the oil shale with particle diameter image 3 or Figure 4 process flow.

[0024] Full column retort layer The segment is 11 layers, the combustion segment 3-6 layers, cooling section 3 layers, spray cooling section for 1 layer, in The carbonization temperature of the section is increased from normal temperature to 550°C layer by layer, and more than 95% of the total oil is obtained by dry distillation. The oil, volatile matter, and carbon residue that have not been dry-distilled enter the combustion section, and 95-98% of the carbon residue in the shale is burned. Provide heat for the retort furnace, the retort process is similar to that of Example 1; the retort time is 30-60min, the retort oil shale produces 95kg of shale oil per ton, the retort gas is 150Nm3, and the calorific value is 4500kcal / Nm3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com