Method For Manufacturing Pressure-sensitive Adhesive Sheet Having Ultraviolet-curable Pressure-sensitive Acrylic Adhesive Agent Layer

A manufacturing method and adhesive layer technology, applied in the direction of non-polymer organic compound adhesives, film/sheet adhesives, adhesives, etc., can solve problems such as poor productivity and long polymerization reaction time, and achieve production Excellent properties, suppression of low molecular weight, and effects of preventing reduction in cohesive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

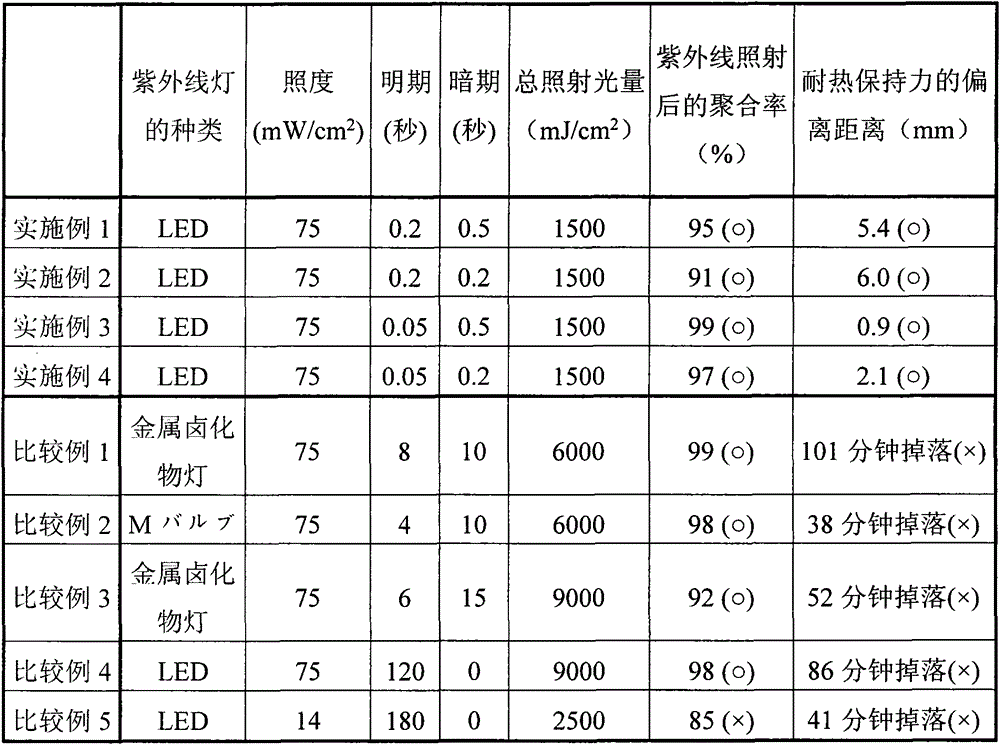

Embodiment 1

[0088] (Preparation of ultraviolet curable acrylic adhesive composition)

[0089] After adding 0.04 parts by weight of 1,6-hexanediol diacrylate to 100 parts by weight of the above-mentioned acrylic polymer slurry 1, the mixture was uniformly mixed to prepare an ultraviolet curable acrylic adhesive composition.

[0090] (production of adhesive sheet)

[0091] On the peeled surface of a polyester film (trade name: MRF, manufactured by Mitsubishi Chemical Polyester Co., Ltd.) with a thickness of 38 μm that has been peeled with silicone on one side, the above-mentioned ultraviolet-curable acrylic film was coated with an applicator. An adhesive composition was used to achieve a final thickness of 60 μm to form a coating layer. After that, a polyester film (trade name: MRN, Mitsubishi Chemical Polyester Co., Ltd. system), so that the release-treated surface of the film was the coating layer side. Thereby, the coating layer of the ultraviolet curable acrylic pressure-sensitive ad...

Embodiment 2

[0093] The bright period time is 0.2 seconds, and the dark period time is 0.2 seconds. Repeat this light-dark cycle until the total light exposure reaches 1500mJ / cm 2 , thereby photopolymerizing the monomer components contained in the above-mentioned ultraviolet curable acrylic pressure-sensitive adhesive composition to obtain a polymer with a polymerization rate of 91%. Then, it dried in 130 degreeC environment for 90 second, and obtained the adhesive sheet of 99% of polymerization rate, it carried out similarly to Example 1, and produced the adhesive sheet.

Embodiment 3

[0095] The bright period time is 0.05 seconds, and the dark period time is 0.5 seconds. Repeat this light-dark cycle until the total light exposure reaches 1500mJ / cm 2 , thereby photopolymerizing the monomer components contained in the above-mentioned ultraviolet curable acrylic pressure-sensitive adhesive composition to obtain a polymer with a polymerization rate of 98%. Then, it dried in 130 degreeC environment for 90 second, and obtained the adhesive sheet of 99% of polymerization rate, it carried out similarly to Example 1, and produced the adhesive sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com