Electrostatic spinning device available for 3D (three-dimensional) printing

A 3D printing and electrospinning technology, which is applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve the problems of easy clogging of needles or small holes in spinning, so as to reduce the discharge of the tip and solve the problem of easy clogging , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

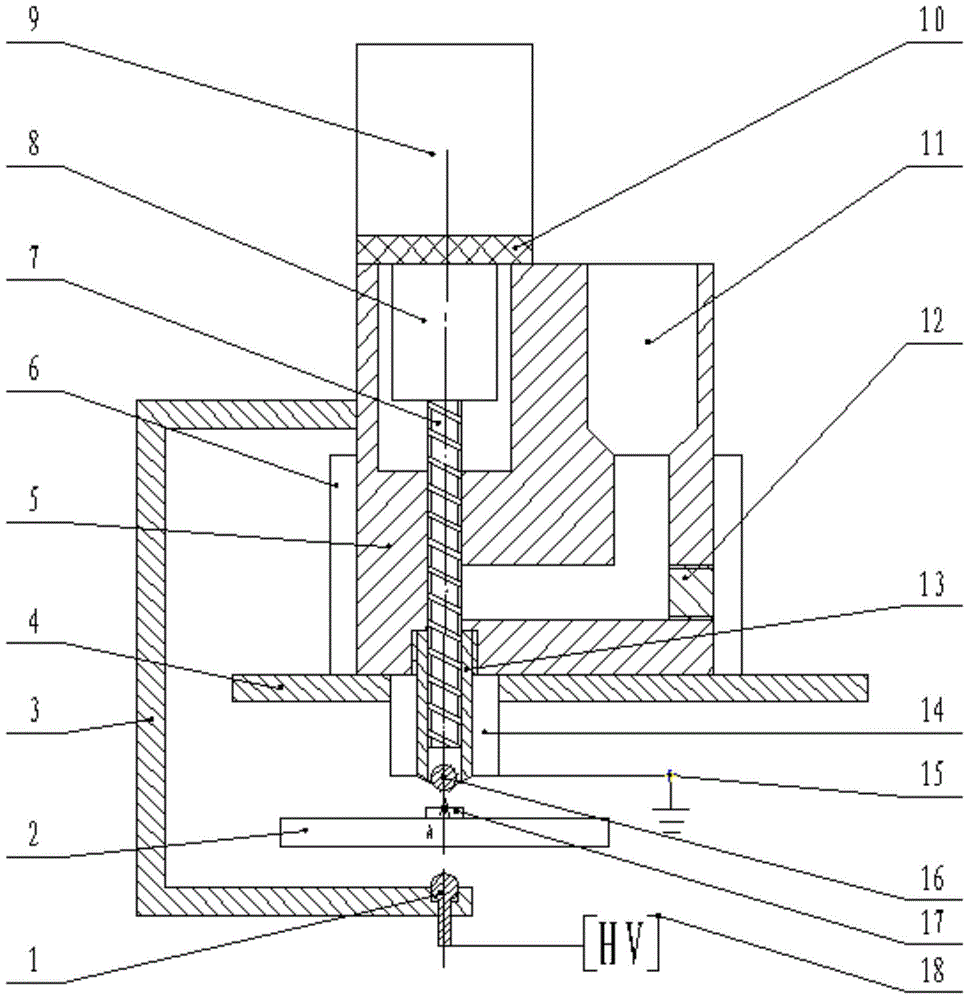

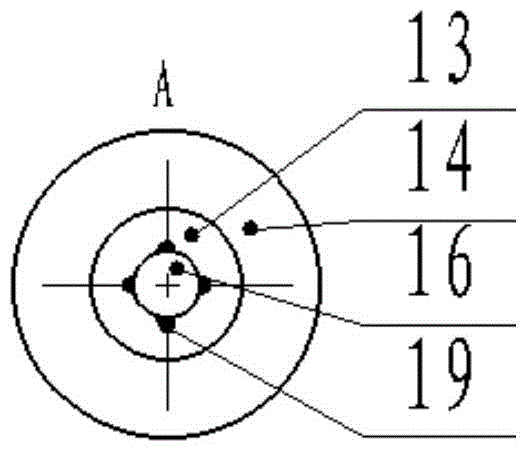

[0024] The present invention proposes an electrospinning device that can be used for 3D printing, such as figure 1 As shown, it mainly includes: spherical high-voltage electrode 1, receiving plate 2, insulating connector 3, fixed bracket 4, machine head 5, machine head heating ring 6, micro screw 7, coupling 8, stepping motor 9, silo 11. Spinning nozzle 13, spinning nozzle heating ring 14, spherical ground electrode 16, workpiece 17 and high-voltage electrostatic generator 18, spherical high-voltage electrode 1 is fixed on the insulating connector 3, and its bottom end and high-voltage electrostatic generator 18 connected, the insulated connector 3 is connected to the machine head 5, and the machine head 5 is fixed on the fixed bracket 4, so that the fixed bracket 4 moves in the X and Y directions, driving the machine head 5 and the spherical high-voltage electrode 1 to move simultaneously, and the stepper The motor 9, the coupling 8 and the micro screw 7 are connected togethe...

Embodiment 2

[0026]Install each component according to the first step of the embodiment, adjust each parameter, print the bottom surface and side profile of the model part according to the set program, the profile thickness is 1-2mm, then automatically close the high-voltage electrostatic generator 18 according to the program, and simultaneously The feeding motor 9 increases the speed to increase the feed rate, and the fixed bracket 4 moves in the X and Y directions according to the program setting, so that the thicker wire fills the inner cavity of the part. After the filling is completed, the device automatically turns on the high-voltage electrostatic generator again according to the program. 18. Adjust the voltage to 7.5kv, reduce the speed of the stepper motor 9 to reduce the feed rate, automatically adjust the distance between the spherical ground electrode 16 and the top of the part to 2mm according to the program, and then print the top structure of the part according to the set prog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com