A remote control system and method for material sorting equipment

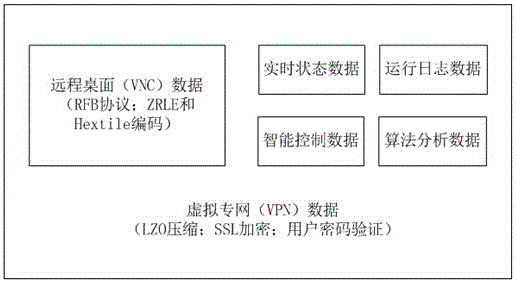

A remote control system and remote control technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve problems such as inability to obtain working information signals and images of material sorting equipment, difficult for customers to solve independently, and difficult operation. , to solve the problem of penetrating gateway and firewall, solve the problem of security and efficiency, and achieve the effect of safe and reliable data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings.

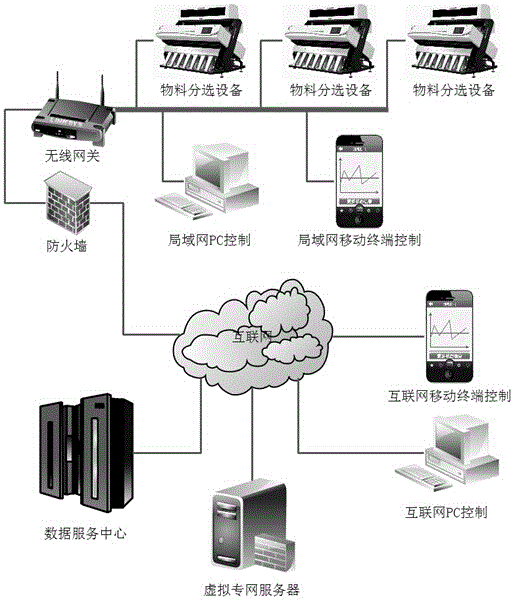

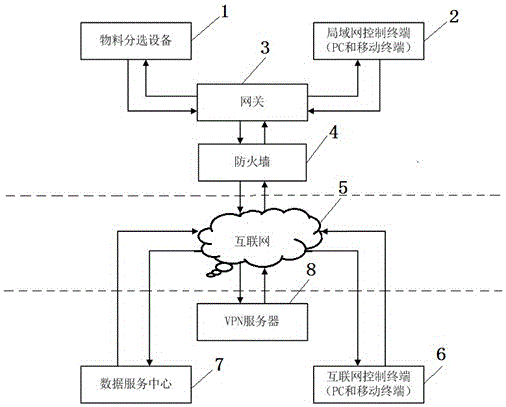

[0037] Such as figure 2 As shown, a remote control system for material sorting equipment, including at least one material sorting equipment 1 set at the customer site, a local area network control terminal 2 and an Internet control terminal 6 set at the after-sales service center, a data service center 7 and the VPN server 8 with public network IP, the local area network control terminal 2 and the Internet control terminal 6 all include PC and mobile terminal; Material sorting equipment 1 and local area network control terminal 2 are connected to the gateway 3 by a star network to form a local area network, And access to the Internet 5 through the firewall 4, the Internet control terminal 6, the data service center 7 and the VPN server 8 are all connected to the Internet 5.

[0038] The working principle of the present invention is described in detail as follows:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com